Cleansing color coated steel plate for purification and preparation method thereof

A color-coated steel plate and surface cleaning technology, applied in the field of materials, to achieve the effect of fine and smooth appearance, not easy to scratch and damage, and high scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

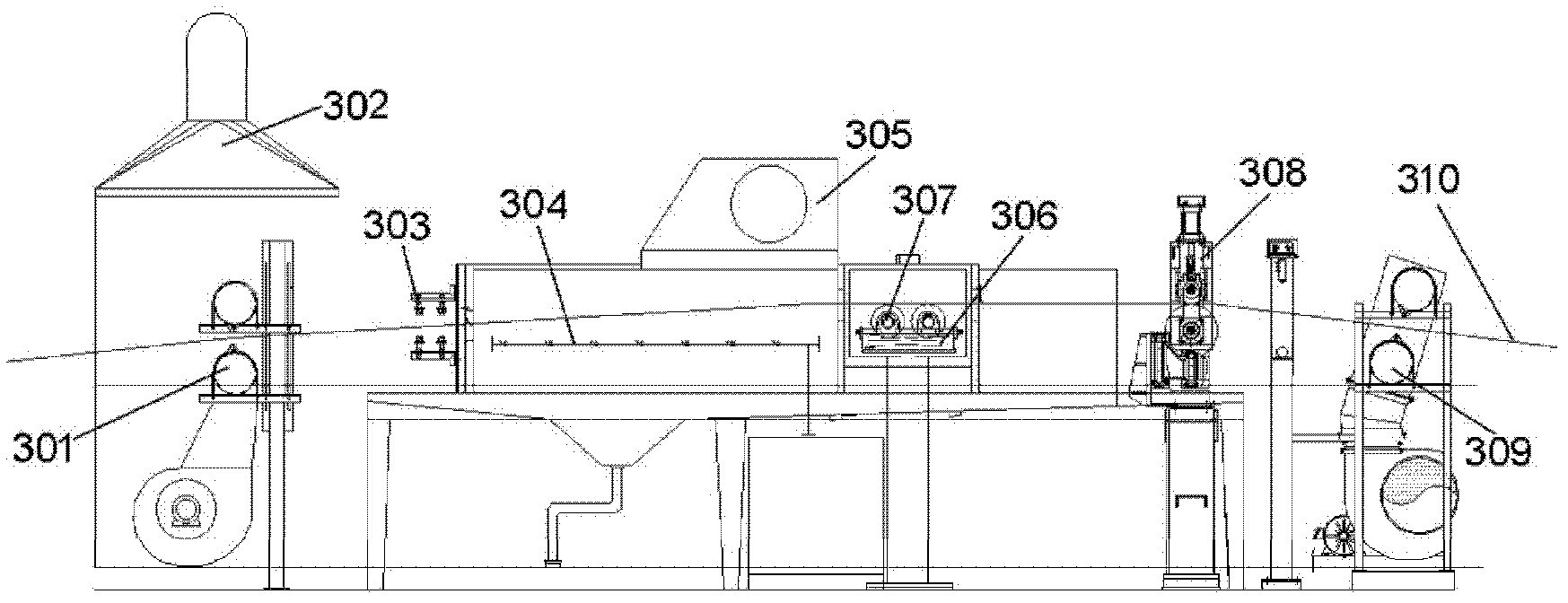

[0050] Using smooth galvanized substrate as the base material, the continuous automatic production process of cleansing color-coated steel sheets for purification and cleaning is briefly described as follows: uncoiling → degreasing I → brush roller grinding → degreasing II → three washings → chemical conversion film → drying →Primer coating / back coating→baking→cooling I→top coating→baking→cooling II→inspection→winding.

[0051] Spray degreasing I adopts alkaline degreasing method, the main components are sodium hydroxide, sodium carbonate, trisodium phosphate, sodium silicate, etc. and surfactants, the temperature of the bath is controlled at 55±5°C; cm 2 ; Effective spraying time is 10 seconds; Degreasing II is to wash the board with the above lye;

[0052] Among the three washings, softened water is used for the first and second washings, and deionized water is used for the third washing to ensure the cleanliness of the substrate surface;

Embodiment 2

[0065] Pollutants include water and carbon black. Under the condition that the preparation ratio is water: carbon black (FW 200) = 85:15, it is made of cleansing color coated steel plate (white ash) and ordinary color steel plate (white ash) for purification respectively. There are three test panels each, and after the pollutants are evenly painted on the surface of the test panels, they are baked in an oven at a temperature of 60°C for 2 hours. After taking them out, they are rinsed with clean running water, and then wiped with absorbent cotton until the carbon black on the coating surface cannot be wiped off. until. Based on the sample plate before the test, the color change was tested with a color difference meter. The stain resistance comparison between the cleansing color coated steel plate of this embodiment and the ordinary color steel plate is shown in Table 3:

[0066]

[0067] table 3

[0068] Note: In Table 3, ΔL, Δa, and Δb refer to the difference in hue change...

Embodiment 3

[0072] Under the condition that the temperature is 23°C, the load of the nylon brush is 454g, and the frequency of back-and-forth brushing is 37 times / min, the comparison of the wiping resistance of the cleansing color-coated steel plate of this embodiment with that of ordinary color-coated steel plates is shown in Table 4:

[0073]

[0074] Table 4

[0075] The results shown in Table 4 are:

[0076] Cleansing color-coated steel plate for purification can withstand an average of 1525 times of wiping

[0077] The average number of wipes of ordinary color steel plate is 1133 times

[0078] Result = number of times of wiping resistance of color-coated steel plate for purification / number of times of wiping resistance of ordinary color steel plate = 135%

[0079] After comparing the results of three groups of tests, the average value is greater than 100%, which shows that the abrasion resistance of the cleansing color-coated steel plate for purification is obviously better t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com