Preparation method of Cu-Zn-Sn-S thin film

A copper-zinc-tin-sulfur and thin-film technology is applied in the direction of final product manufacturing, sustainable manufacturing/processing, solid-state chemical plating, etc., to avoid the use of potassium cyanide and organic additives, simple and applicable process methods, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

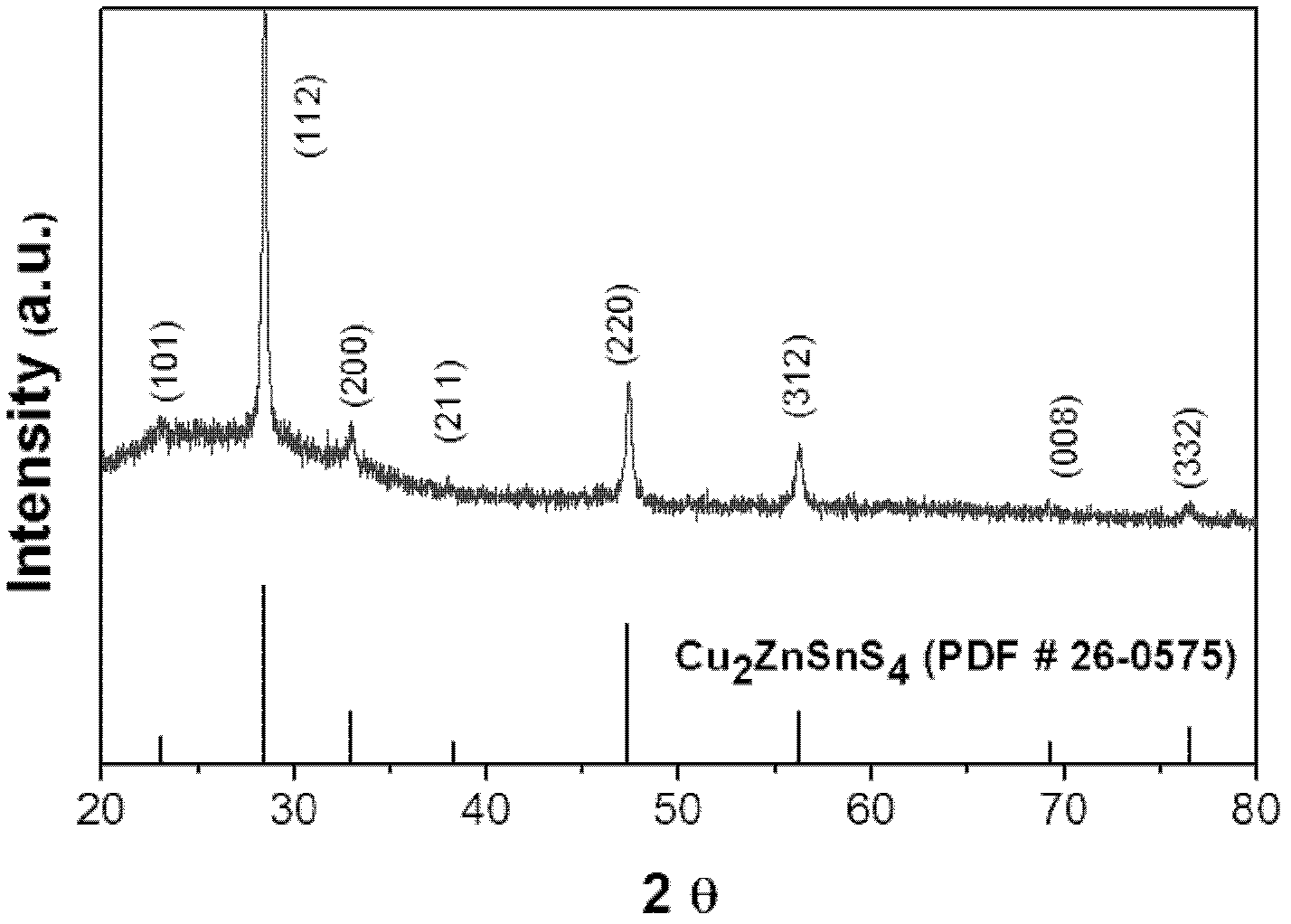

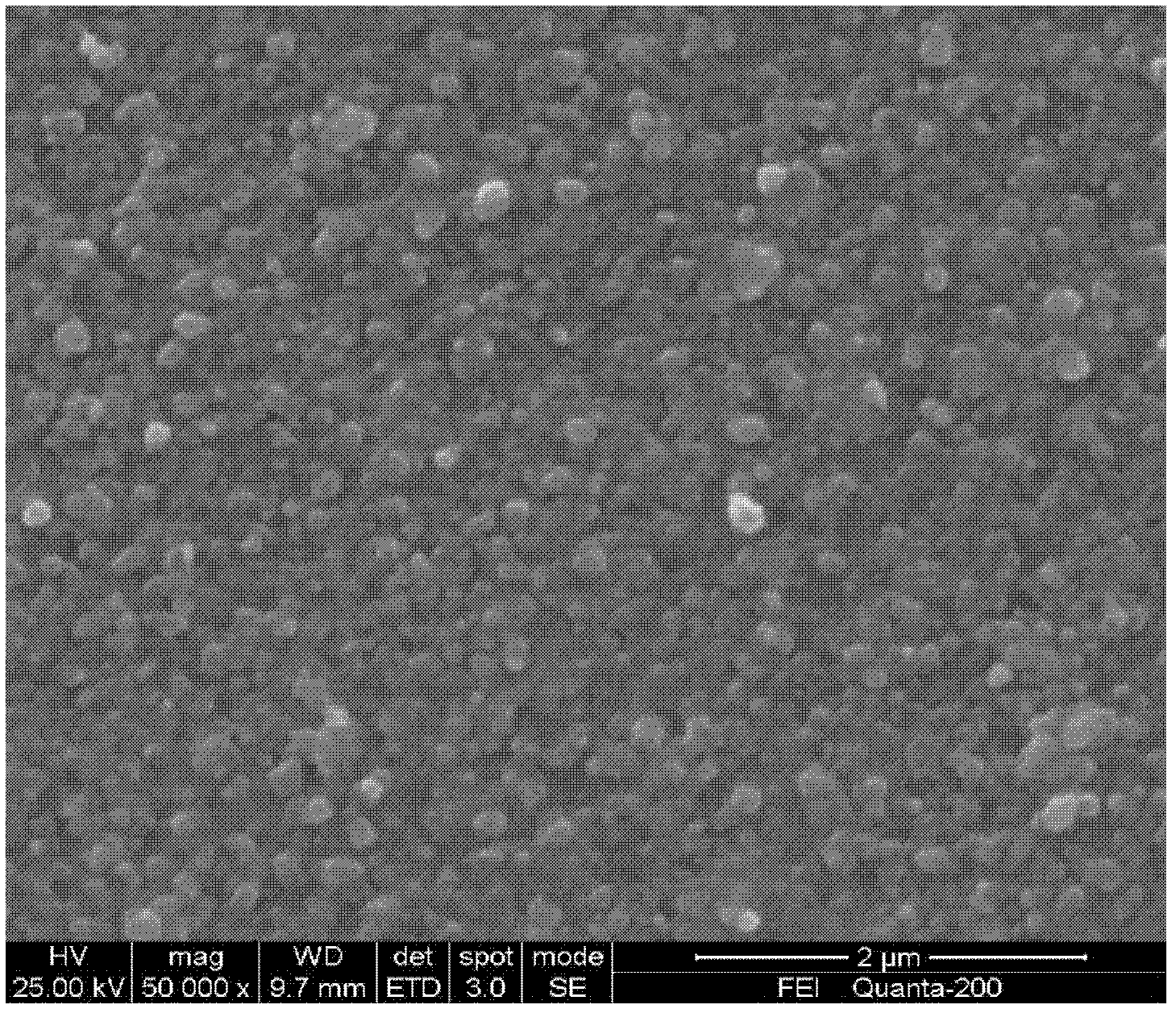

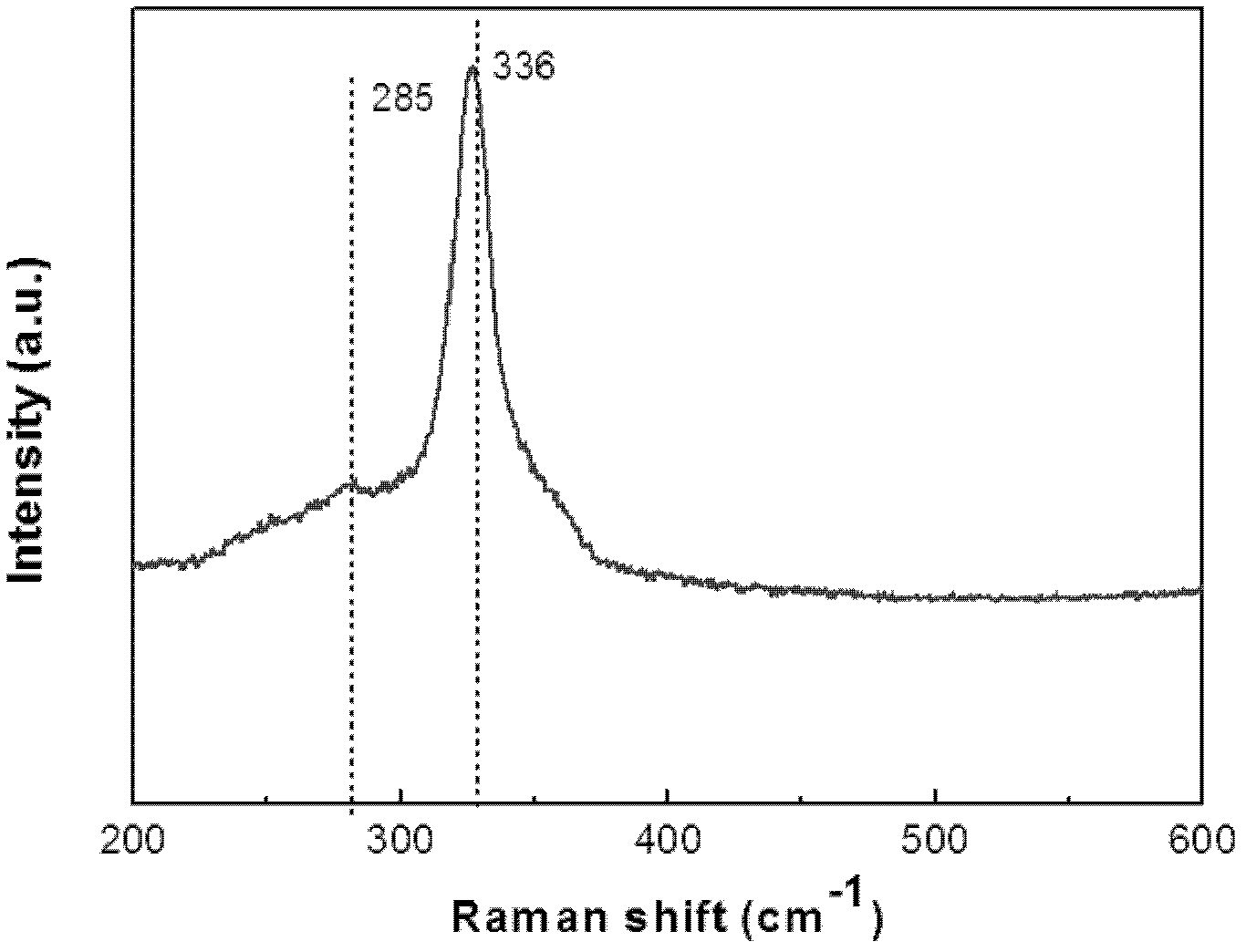

[0025] Step 1. Preparation of Cu 2 SnS x film:

[0026] 1. Preparation of cationic precursor solution: the medicines used are analytical reagents and prepared with deionized water. Weigh a certain amount of CuSO 4 , SnSO 4 and tartaric acid, mixed together to prepare a 100ml solution and placed in a 200ml beaker, in which CuSO 4 , SnSO 4 The molar concentrations of tartaric acid and tartaric acid are 0.01M / L, 0.05M / L and 1.0M / L respectively;

[0027] 2. Preparation of anion precursor solution: weigh a certain amount of Na 2S is prepared into a 100ml solution and placed in a beaker, Na 2 The molar concentration of S is 0.05M / L;

[0028] 3. Immerse the glass slides cleaned by dilute sulfuric acid, ammonia water and absolute ethanol in the mixed cation solution for surface adsorption for 20 seconds, then immerse in the flowing deionized water container for 20 seconds, and then immerse in the anion precursor Body Na 2 React in S solution for 20 seconds, and finally wash ...

Embodiment 2

[0038] Step 1. Preparation of Cu 2 S film:

[0039] 1. Preparation of cationic precursor solution: the medicines used are analytical reagents and prepared with deionized water. Weigh a certain amount of CuSO 4 and ammonia, mixed together to prepare a 100ml solution and placed in a 200ml beaker, where CuSO 4 The molar concentrations of ammonia and ammonia are 0.02M / L and 1.0M / L respectively;

[0040] 2. Preparation of anion precursor solution: weigh a certain amount of Na 2 S is prepared into a 100ml solution and placed in a beaker, Na 2 The molar concentration of S is 0.06M / L;

[0041] 3. Immerse the glass slides cleaned by dilute sulfuric acid, ammonia water and absolute ethanol in the mixed cation solution for surface adsorption for 20 seconds, then immerse in the flowing deionized water container for 20 seconds, and then immerse in the anion precursor Body Na 2 React in S solution for 20 seconds, and finally wash the glass slide with flowing deionized water for 20 se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com