Halogen-free fire retardant containing benzoxazine and polymer material comprising same

A technology of benzoxazine and flame retardant, which is applied in the field of halogen-free flame retardants, can solve the problems of low cost and high production cost, and achieve the effects of good flame retardancy, good compatibility and good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

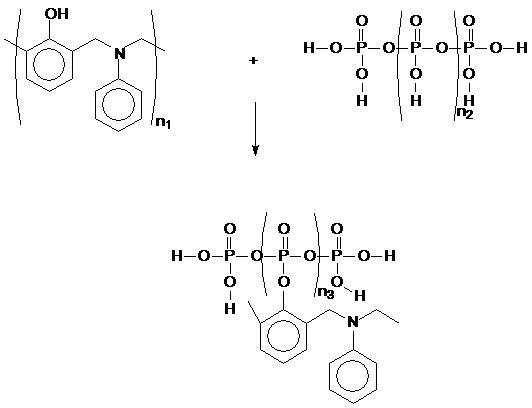

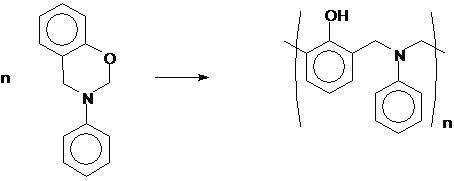

Method used

Image

Examples

Embodiment 1-8

[0058] The preparation process of Comparative Examples 1-2 and Examples 1-8: After a certain amount of ABS or HIPS is plasticized on a double-roll mill at 170-180°C, antioxidants (mass Antioxidants 1076 and 168 with a ratio of 1:1), benzoxazine resin, microcapsule red phosphorus and other raw materials, after mixing evenly, put them in the mold after discharging, and heat press on a flat vulcanizing machine at 180°C for 10 Minutes, then cold press at room temperature for 10 minutes, and then molded boards for performance testing. The test standard is shown in Table 6.

[0059] The physical properties of the benzoxazine-based halogen-free flame-retardant ABS in the comparative examples and examples are shown in Table 2, and the test standards are shown in Table 6. In Example 1, 9 parts of bisphenol A-type benzoxazine was used to replace 9 parts of microencapsulated red phosphorus, and the tensile strength, impact strength and flame retardancy of the material prepared were all ...

Embodiment 9~10

[0065] After mixing all the components in proportion (see Table 3), put them into a twin-screw extruder for melt extrusion, and the extrusion temperature is 200~250°C. The extruded material is granulated and post-processed, and then injection molded to obtain test specimens. Antioxidants are selected from antioxidant 1076 and 168 composite antioxidants with a mass ratio of 1:1. Table 3 flame retardant PC / ABS alloy formula / (weight part)

[0066]

[0067] The physical properties of the benzoxazine-based halogen-free flame-retardant PC / ABS alloys in the comparative examples and examples are shown in Table 4, and the test standards are shown in Table 6.

[0068] Table 4 Physical Properties of Flame Retardant PC / ABS Alloy

[0069] project Comparative example Example 9 Example 10 Tensile strength (MPa) 52 46 42 Notched impact strength (KJ m -2 ) 42 38 32 Flame retardant (1.6mm) combustion V-1 V-0

Embodiment 11

[0071] Mix 10 parts of BPOZ with 10 parts of red phosphorus powder and 0.2 parts of magnesium hydroxide evenly, and then add them to a twin-screw extruder with a temperature set at 120°C to extrude and granulate to obtain a non-toxic compound containing benzoxazine and red phosphorus. Halogen flame retardant A.

[0072] Mix 10 parts of ABS with 1.8 parts of the above-mentioned halogen-free flame retardant A containing benzoxazine and red phosphorus, extrude and granulate on a twin-screw extruder at 200°C, and then put the obtained flame-retardant ABS on an injection molding machine at Sample preparation by injection molding at 220°C. The properties of the obtained samples are shown in Table 5

[0073] Table 5 Example 11 sample properties

[0074] project Example 11 Tensile strength (MPa) 35 Notched impact strength (KJ m -2 ) 6.3 Flame retardant (1.6mm) V-0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com