Niobate-series leadless piezoelectric ceramic-polymer three-phase composite material with high dielectric constant

A lead-free piezoelectric and composite material technology is applied in the field of high dielectric composite materials to achieve the effects of high dielectric constant, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

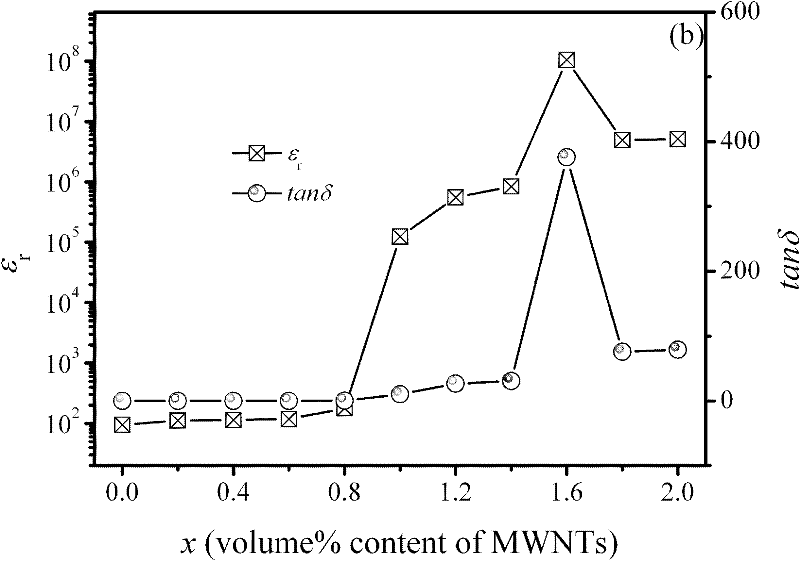

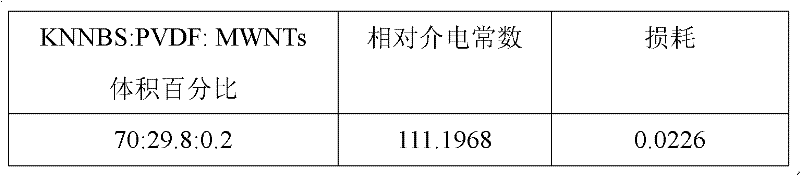

[0031] The lead-free piezoelectric ceramic fine powder KNNBS was prepared according to the above-mentioned materials and preparation process steps, and the prepared KNNBS, PVDF and MWNTs were prepared into composite powder according to the volume fraction of 70:29.8:0.2; the composite powder was placed in In the tablet press, a disc with a diameter of 10mm and a thickness of 0.5mm was pressed into a disc with a diameter of 10mm and a thickness of 0.5mm; the obtained disc was placed in a muffle furnace and heat-treated at a temperature of 80°C for 2h to obtain KNNBS-PVDF- MWNTs three-phase composite material sample; Sputter the gold electrode on the surface of the obtained sample with a small ion sputtering instrument; after standing in the air for 24 hours, test the relative dielectric constant and dielectric loss of the sample at 1kHz; the ingredients used in this example The volume percentage, and the relative dielectric constant and dielectric loss of the measured samples are...

Embodiment 2

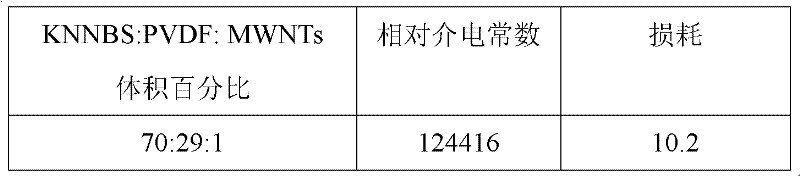

[0035] As in Example 1, the lead-free piezoelectric ceramic fine powder KNNBS was prepared according to the above-mentioned materials and preparation process steps, and the prepared KNNBS, PVDF and MWNTs were formulated into composite material powder according to the volume fraction of 70:29:1; Place the composite material powder in a tablet press and press 10 MPa pressure to form discs with a diameter of 10 mm and a thickness of 0.5 mm; the obtained discs are placed in a muffle furnace and heat treated at a temperature of 150 ℃ for 4 hours, namely Prepare the KNNBS-PVDF-MWNTs three-phase composite material sample; Sputter the gold electrode on the surface of the obtained sample with a small ion sputtering apparatus; after standing in the air for 24 hours, test the relative permittivity and dielectric constant of the sample at 1kHz Electrical loss; the volume percentage of ingredients used in this example, and the relative dielectric constant and dielectric loss of the measured ...

Embodiment 3

[0039] As in Example 1, the lead-free piezoelectric ceramic fine powder KNNBS was prepared according to the above-mentioned materials and preparation process steps, and KNNBS, PVDF and MWNTs were prepared into composite powder according to the volume fraction of 70:28.4:1.6; the composite material The powder is placed in a tablet press and pressed into a disc with a diameter of 10 mm and a thickness of 0.7 mm under a pressure of 18 MPa; the obtained disc is placed in a muffle furnace and heat-treated at a temperature of 220° C. for 8 hours to obtain KNNBS -PVDF-MWNTs three-phase composite material sample; Sputter the gold electrode on the surface of the obtained sample with a small ion sputtering instrument; after standing in the air for 24 hours, test the relative dielectric constant and dielectric loss of the sample at 1kHz; The volume percentage of ingredients used in the example, and the relative dielectric constant and dielectric loss of the measured samples are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com