Environment-friendly flame-retardant nylon 6 nano composite material and preparation method thereof

A nano-composite material and environmental technology, applied in the direction of fibrous filler, dyed low molecular organic compound treatment, etc., can solve the problems of poor clay peeling and dispersing effect, poor heat resistance of flame retardants, unfavorable processing, etc., and achieve good peeling effect, The effect of excellent flame retardant performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

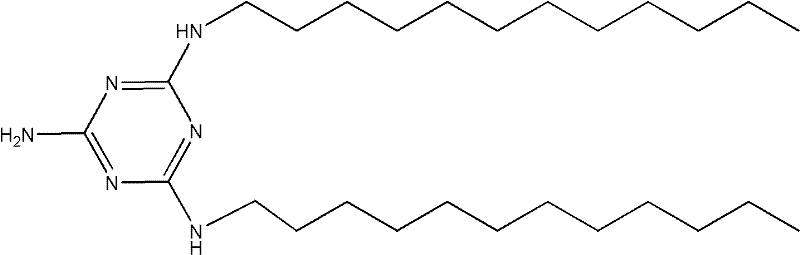

[0033] Weigh 35g of concentrated ammonia solution (mass percentage concentration 25%, Beijing Chemical Plant) and put it into a volumetric flask, then add deionized water to constant volume 500ml, stir and leave it behind and transfer it to an Erlenmeyer flask. Store at low temperature. Weigh 9.24g of cyanuric chloride (CC) (Beijing Bailingwei Technology Co., Ltd.) and dissolve it in about 100ml of ice acetone (stored at 0°C for at least 24h), and quickly pour it into a three-neck flask filled with about 80ml of ice water at low temperature , the entire reaction system was placed in an ice bath environment. Add dropwise 100ml of ice ammonia water prepared above with a concentration of 1mol / L. The whole dropping process lasts for about 10 minutes. After the dropping is completed, start timing. The temperature of the reaction solution is controlled at 0°C or 5°C (within this temperature range There is basically no difference in the performance of the prepared organoclay) for 30...

Embodiment 2

[0037] Dry nylon 6 slices (Zhuangyuan Shijiazhuang Refining and Chemical Company), epoxy resin (Phoenix Bluestar New Material Wuxi Resin Factory), MPP (Xingxing Zhejiang Xingxing Flame Retardant Company), organoclay at 80°C for 36 hours, and mix briefly Finally, it is added to a HT-30 twin-screw extruder with a diameter of 30 mm and an aspect ratio of 48 for mixing. The extrusion temperature of the extruder is 225° C., the feeding speed is 20 r / min, and the screw speed is 300 r / min. After compounding, the materials were cut into pellets and dried at 80°C for 24 hours.

[0038] The pellets of the nanocomposite prepared above were injection molded in a HTF80X1 injection molding machine. The injection molding temperature of the injection machine is 230° C., the injection pressure is 30 MPa, the holding time is 20 seconds, and the cooling time is 30 seconds. Injection molded sample sizes are 130mm×13mm×3.2mm and 100mm×100mm×3mm.

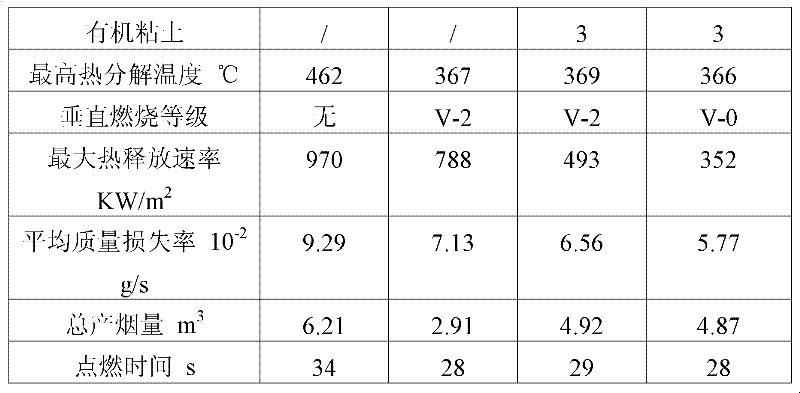

[0039] The nanocomposite samples prepared above...

Embodiment 3

[0047] Nylon 6 slices, MPP, epoxy resin, nanoclay (Cloisite Na + Southern Clay Company, US) was dried at a temperature of 80° C. for 36 hours, and after simple mixing, it was added to a HT-30 twin-screw extruder with a diameter of 30 mm and an aspect ratio of 48 for mixing. The extrusion temperature of the extruder is 225°C, the feeding speed is 20r / min, the screw speed is 300r / min, after processing, it is cut into pellets and dried at 80°C for 24 hours.

[0048] The pellets of the nanocomposite prepared above were injection molded in a HTF80X1 injection molding machine. The injection temperature of the injection molding machine is 230° C., the injection pressure is 30 MPa, the holding time is 20 seconds, and the cooling time is 30 seconds. The injection-molded nanocomposites are nylon 6 / clay nanocomposites, nylon 6 / MPP / clay nanocomposites, and nylon 6 / MPP / epoxy resin / clay nanocomposites. The sample size is 130mm x 13mm x 3.2mm and 100mm x 100mm x 3mm. The prepared nanocomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com