Non-aldehyde acidification corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and corrosion inhibitor, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve the problems of poor temperature resistance, hidden dangers in construction, large formation damage, etc., and achieve good high-temperature corrosion inhibition performance and responsive The effect of mild conditions and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

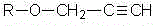

[0027]

[0028] According to propynyl alcohol: potassium hydroxide molar ratio 1:1.05, propynyl alcohol, potassium hydroxide and appropriate amount of water were stirred and reacted at room temperature for 1 hour to generate alkynyl alcohol potassium salt, and benzyl chloride equivalent to propynyl alcohol was added , at 100 0 The reaction was continued at C for 8 hours to obtain a brown-yellow product.

[0029] Will content be:

[0030] Chlorinated benzyl propargyl alcohol ether: 20% by weight, Fatty alcohol polyoxyethylene ether : 4.5% by weight, Methanol : 75% by weight, potassium iodide: 0.5% by weight, stirred evenly.

Embodiment 2

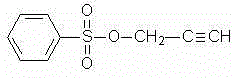

[0032]

[0033] According to propynyl alcohol: potassium hydroxide molar ratio 1:1.05, propynyl alcohol, potassium hydroxide and appropriate amount of water are stirred and reacted at normal temperature to generate acetylenic alcohol potassium salt, and benzenesulfonyl chloride having an equimolar ratio to propynyl alcohol is added, 100 0 The reaction was continued at C for 7 hours to obtain a brown product.

[0034] Containing benzenesulfonyl propynyl alcohol ether: 50% by weight, Alkylphenol polyoxyethylene ether : 3% by weight, ethanol : 46.5% by weight, potassium iodide: 0.5% by weight, stirred evenly.

Embodiment 3

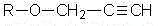

[0036]

[0037] According to propynyl alcohol: potassium hydroxide molar ratio 1:1.05, propynyl alcohol, potassium hydroxide and appropriate amount of water are stirred and reacted at normal temperature to generate acetylenic alcohol potassium salt, and benzoyl chloride having an equimolar ratio to propynyl alcohol is added, and 90 0 The reaction was continued for 8 hours at C to obtain a dark brown product.

[0038] Containing benzoyl propynyl alcohol ether: 40% by weight, nonionic surfactant: 5% by weight, Isopropanol : 54% by weight, potassium iodide: 1% by weight, stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com