Biological regeneration diesel oil produced by use of food waste grease and manufacturing method thereof

A bio-regeneration and kitchen waste technology, which is applied in the fields of fat oil/fat refining, biofuel, petroleum industry, etc., and can solve problems such as equipment indigestion and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Food remnants, slops, non-edible animal and plant waste edible oils and oil-water mixtures produced in hotels, guesthouses, catering industries, government agencies, schools, enterprise units and other canteens during food processing and catering activities. The waste oil from food waste extracted after mechanical oil-water separation is set aside for use;

[0043] After the fruit of Jatropha curcas is picked, dried and separated, the seeds are crushed, heated, steamed and fried, and the extracted Jatropha oil is processed by mechanical pressing for use;

[0044] A kind of rice bran separated from rice through mechanical processing is steam-heated, and the rice bran oil extracted by mechanical pressing is set aside;

[0045] Cotton seeds are dried, processed and separated, crushed, heated, steamed and fried, and the extracted cottonseed oil is processed by mechanical pressing for use;

[0046] A kind of grain separated from the fruit of the saponin tree after being dri...

Embodiment 2

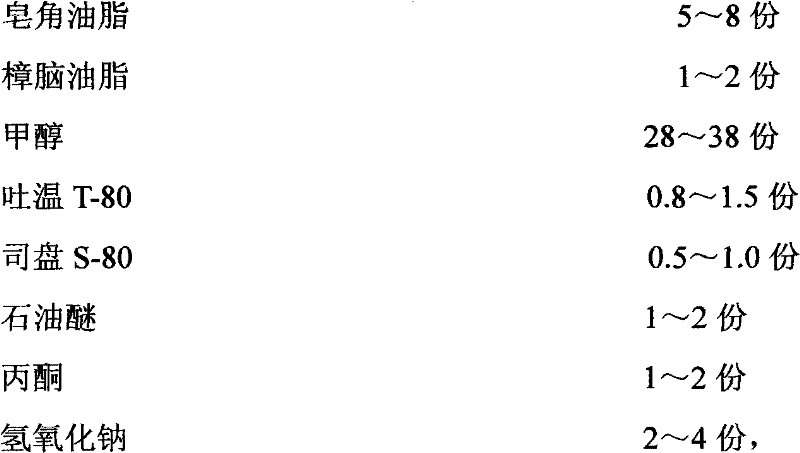

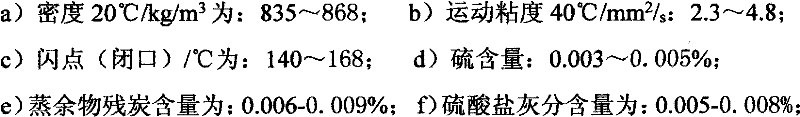

[0052] Get the kitchen waste waste oil 40kg of embodiment 1, jatropha oil 35kg, rice bran oil 15kg, cottonseed oil 25kg, saponin oil 8kg, camphor oil 2kg, methyl alcohol 38kg, Tween T-80: 1.5kg, Span S -80: 1.0kg, 2kg of petroleum ether, 2kg of acetone, and 4kg of sodium hydroxide. Mix the above raw materials with a paddle stirrer and preheat them evenly. The temperature is controlled at 60°C. Pump them into the reaction kettle for transesterification and filtration. After entering the oil storage tank, it is made into a bio-regenerated diesel product from kitchen waste waste oil. After testing:

[0053] Both meet the national standards of GB / T20828-2007 and GB16663-1996 of the People's Republic of China. For qualified products.

Embodiment 3

[0055] Get the kitchen waste waste oil 33kg of embodiment 1, Jatropha curcas oil 28kg, rice bran oil 11kg, cottonseed oil 18kg, saponin oil 6kg, camphor oil 1.3kg, methyl alcohol 30kg, Tween T-80: 1.0kg, Span S-80: 0.6kg, 1.3kg of petroleum ether, 1.3kg of acetone, and 2.5kg of sodium hydroxide. Mix the above raw materials with a paddle stirrer and preheat them evenly. The temperature is controlled at 30°C. Pump them into the reaction kettle for transesterification. , After filtration and purification, it enters the oil storage tank, and then it is made into a bio-regenerated diesel product from kitchen waste waste oil. After testing:

[0056] Both meet the national standards of GB / T20828-2007 and GB16663-1996 of the People's Republic of China. For qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com