Polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete and preparation method thereof

A technology of lightweight aggregate concrete and polystyrene particles, applied in ceramic products, other household appliances, sustainable waste disposal, etc., can solve the problem of poor workability between lightweight raw materials and concrete, high density of lightweight aggregate concrete, thermal insulation Insufficient effect and other problems, to achieve good toughness, good shock resistance, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

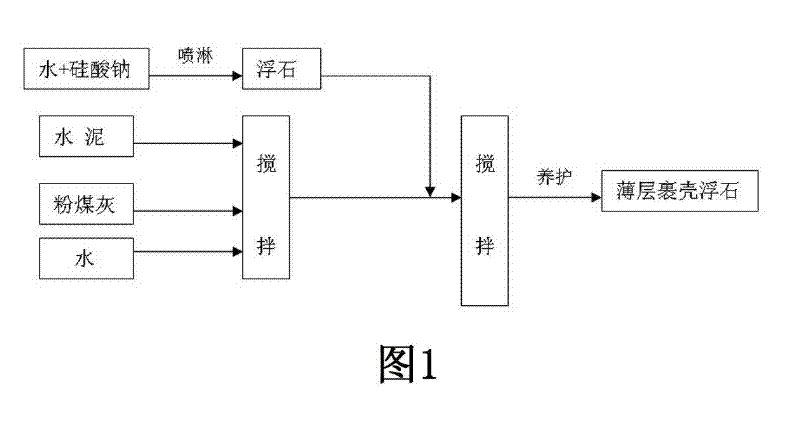

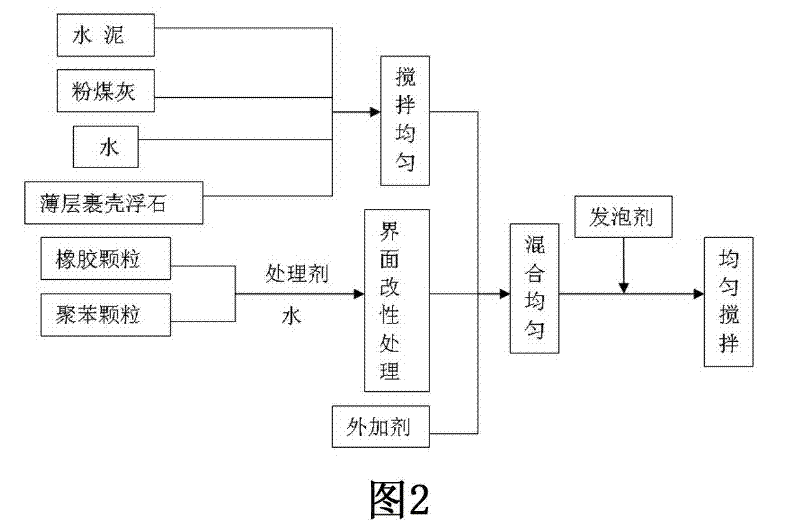

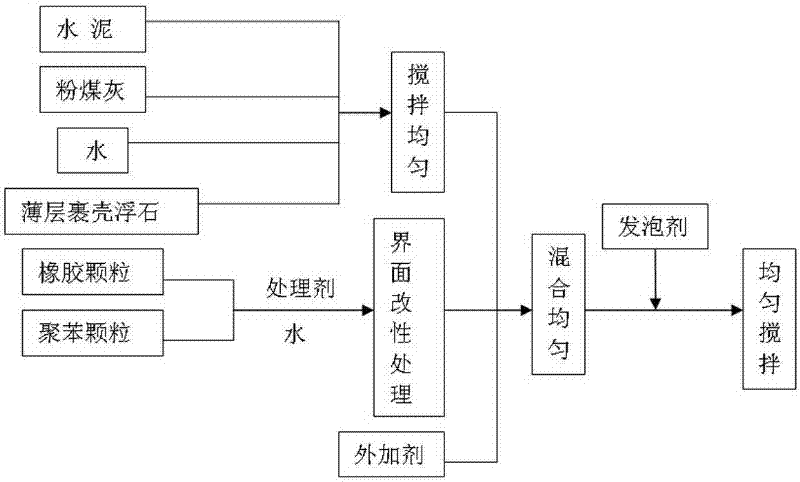

Method used

Image

Examples

Embodiment 2

[0055] Embodiment two, this polystyrene granule-rubber granule-pumice composite lightweight aggregate concrete, described its raw material ratio by weight is as follows:

[0056] 1 part of cement;

[0057] 0.42 parts of fly ash;

[0058] 1.063 parts of pumice sand;

[0059] 0.003 parts of polystyrene particles;

[0060] 0.088 parts of rubber particles;

[0061] Admixture 0.012 parts;

[0062] Foaming agent 0.007 part;

[0063] 0.55 parts of water.

[0064] The pumice sand is used after being processed into a thin layer of shell-coated pumice sand. The polystyrene particles and rubber particles are polystyrene particles and rubber particles that have been treated with an interface treatment agent. The interface treatment agent is sodium silicate for silane coupling agent. Diluted in aqueous solution.

Embodiment 3

[0065] Embodiment three, this polystyrene particle-rubber particle-pumice composite lightweight aggregate concrete, described its raw material ratio by weight is as follows:

[0066] 1 part of cement;

[0067] 0.50 parts of fly ash;

[0068] Pumice sand 0.709 part;

[0069] 0.004 parts of polystyrene particles;

[0070] 0.133 parts of rubber particles;

[0071] Admixture 0.010 parts;

[0072] Foaming agent 0.005 part;

[0073] 0.55 parts of water.

[0074] The pumice sand is used after being processed into a thin layer of shell-coated pumice sand. The polystyrene particles and rubber particles are all polystyrene particles and rubber particles that have been treated with an interface treatment agent. The interface treatment agent is silica gel for titanate coupling agent Diluted with sodium bicarbonate solution.

Embodiment 4

[0075] Embodiment four, this polystyrene particle-rubber particle-pumice composite lightweight aggregate concrete, its raw material ratio by weight is as follows:

[0076] 1 part of cement;

[0077] 0.40 parts of fly ash;

[0078] 0.843 parts of pumice sand;

[0079] 0.003 parts of polystyrene particles;

[0080] 0.122 parts of rubber particles;

[0081] Admixture 0.015 parts;

[0082] Foaming agent 0.007 part;

[0083] 0.54 parts of water.

[0084] The pumice sand is used after being processed into a thin layer of shell-coated pumice sand. The polystyrene particles and rubber particles are polystyrene particles and rubber particles that have been treated with an interface treatment agent. The interface treatment agent is sodium silicate for silane coupling agent. Diluted in aqueous solution.

[0085] In the above-mentioned embodiments 1 to 4, the particle diameter of the pumice sand is 2-6 mm. The particle diameter of the polyphenylene particles is 4-7mm. The parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com