Method for removing nitrogen and phosphorus in sewage by zeolite synthesized by coal ash

A technology for synthesizing zeolite and fly ash, which is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. Improved removal rate, lower production costs and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of low calcium fly ash synthetic zeolite material

[0018] This embodiment utilizes low-calcium fly ash to synthesize zeolite, and the main component of low-calcium fly ash is: SiO 2 48.48%, Al2 o 3 34%, Fe 2 o 3 3.1%, CaO 4.11%. The alkaline activator adopts calcium carbonate. Weigh 1kg of low-calcium fly ash and 1.4kg of sodium carbonate, mix the low-calcium fly ash and sodium carbonate evenly, put them in a muffle furnace and roast at 600°C for 3 hours, take out the samples and cool them, and crush them with a pulverizer , the pulverized sample is mixed with water, the mixing ratio is 1:4, the mixed suspension is stirred at 50°C for 3h to prepare silica-alumina gel, the prepared silica-alumina gel is put into a reaction kettle, and crystallized at 100°C for 9h After the sample was taken out, it was washed with distilled water until the pH of the washing liquid was 9, and after the washed sample was dried, it was ground to synthesize zeolite...

Embodiment 2

[0019] Example 2 Preparation of high calcium fly ash synthetic zeolite material

[0020] This embodiment utilizes high-calcium fly ash to synthesize zeolite, and the main component of high-calcium fly ash is: SiO 2 30.76%, Al 2 o 3 14.31%, Fe 2 o 3 10.27%, CaO 37.55%. Alkaline activator uses sodium hydroxide. Weigh 7.5kg of high-calcium fly ash, then weigh 9kg of sodium hydroxide, mix the high-calcium fly ash and sodium hydroxide evenly, put them in a muffle furnace and roast at 550°C for 2 hours, take out the sample and cool it, and use a pulverizer to Pulverize it, mix the pulverized sample with water, the mixing ratio is 1:5, stir the mixed suspension at 80°C for 1h to prepare silica-alumina gel, put the obtained silica-alumina gel into the reaction kettle, and heat it at 100°C The crystallization was carried out for 16 hours. After the sample was taken out, it was washed with distilled water until the pH of the washing solution was 9. After the washed sample was drie...

Embodiment 3

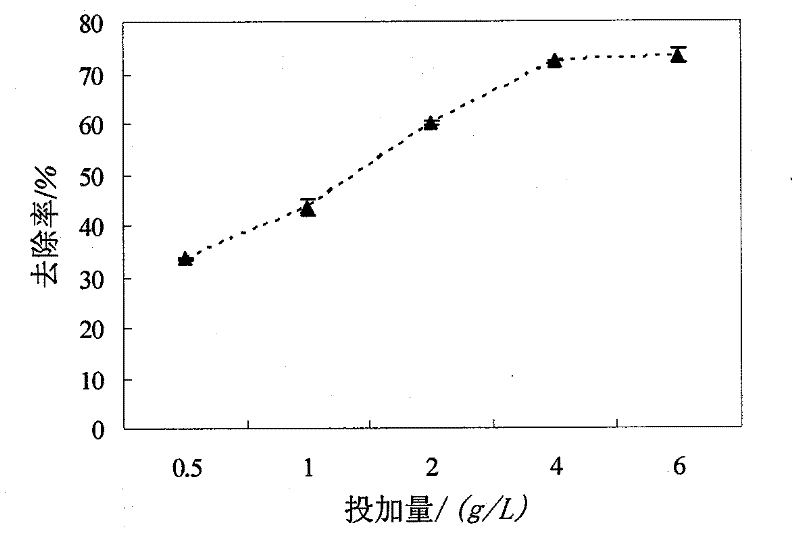

[0021] Example 3 Nitrogen removal effect of low calcium fly ash synthetic zeolite

[0022] The sewage in this embodiment adopts simulated waste water, only containing ammonium ion (NH 4 + -N), using ammonium chloride (analytical pure) configuration. The ammonia root concentration of the wastewater is 10mg / L, and the pH is 6.7. Take 0.1g of low-calcium fly ash synthetic zeolite and put it into 25mL of simulated wastewater, and stir it rapidly for 1h. After solid-liquid separation, the ammonium root concentration in the supernatant is 2.23mg / L, the removal rate of ammonia nitrogen is 78.7%, and the adsorption capacity of ammonia nitrogen is 1.97 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com