Polytetrafluoroethylene-modified polyethylene wax with core-shell structure and preparation process thereof

A polytetrafluoroethylene and polyethylene wax technology, applied in the direction of coating, can solve the problems of easy sedimentation, incompatibility, heavy specific gravity, etc., and achieve good lubrication, wear resistance and chemical inertness, easy to disperse, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

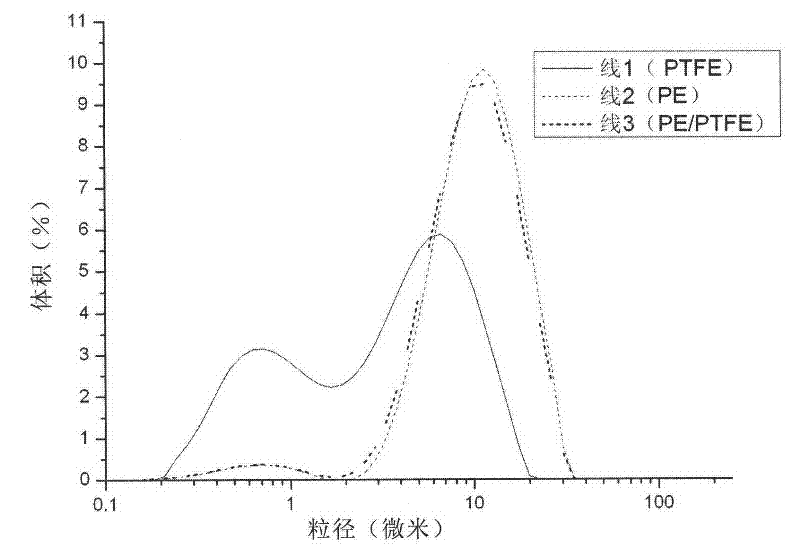

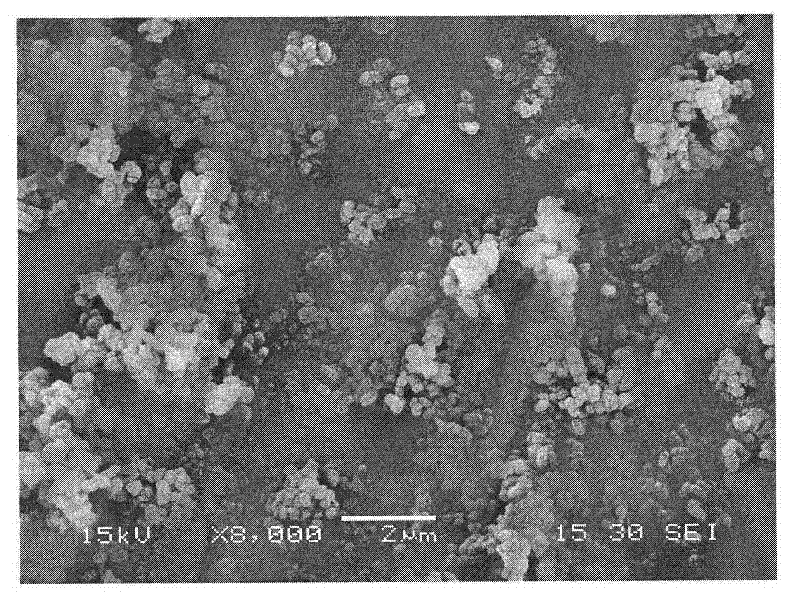

[0076] Firstly, the polytetrafluoroethylene resin JF-4D was irradiated and degraded. The GJ-2 electron accelerator was used to control the irradiation dose at 50 Mrad. The degraded polytetrafluoroethylene resin is subjected to an exhaust and degassing process to remove small molecular gases generated by degradation. Then use jet mill QYF-600 to continue to grind PTFE until the average aggregated particle size is 4 μm, and the maximum aggregated particle size is 15 μm, and the particle size is measured by laser diffraction on the MS2000 type particle size analyzer produced by Malvern ( figure 1 ). From electron micrographs ( figure 2 ) It can also be seen that the ground PTFE is formed by agglomeration of nano-scale small particles, and the size of the particles is about 200 nanometers.

[0077] Add the obtained polytetrafluoroethylene fine powder and polyethylene wax powder D-9 into a high-speed mixer at a weight ratio of 1:6 and stir at high speed for 5 minutes, wherein 2 ...

Embodiment 2

[0082] Similarly, PTFE is degraded by irradiation as in Example 1, wherein the irradiation dose is controlled to be 20 Mrad. Next, the PTFE is ground and pulverized to an average aggregate particle size of 4 μm and a maximum aggregate particle size of 15 μm. The obtained PTFE fine powder is blended at a high speed with polyethylene wax powder D-9, wherein PTFE is 1kg, polyethylene wax powder is 12kg, and the stirring speed is 1300rpm, stirred for 5 minutes, and PTFE modified PE wax powder can be obtained equally. Its average particle size is 9 μm. Figure 7-8 is his electron microscope photo, in which Figure 8 is a magnified photograph of a single particle.

Embodiment 3

[0084] Similarly, PTFE is degraded by irradiation as in Example 1, wherein the irradiation dose is controlled to be 50Mrad. Next, the PTFE is ground and pulverized to an average aggregate particle size of 3 μm and a maximum aggregate particle size of 14 μm. See Figure 9 Middle curve 1. Use polyethylene wax powder WN-1495 with an average particle size of 5.5 μm and a maximum particle size of 14 μm, see Figure 9 Middle curve 2. The obtained PTFE fine powder is blended with polyethylene wax powder WN-1495 at a high speed, wherein PTFE is 2kg, polyethylene wax powder is 10kg, the stirring speed is 1300rpm, stirred for 5 minutes, and PTFE modified PE wax powder can also be obtained. Its average particle size is 5.5μm, and the maximum particle size is 15.5um ( Figure 9 Curve 3). Also in the scanning electron microscope photos, we can also clearly see that PTFE is completely coated on the surface of PE wax powder in the form of nano-spheres. Figure 10-11 It is a scanning el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com