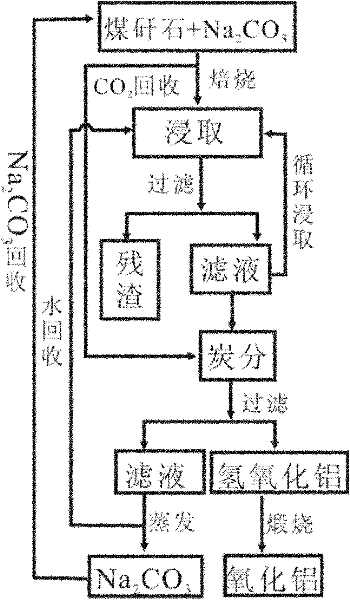

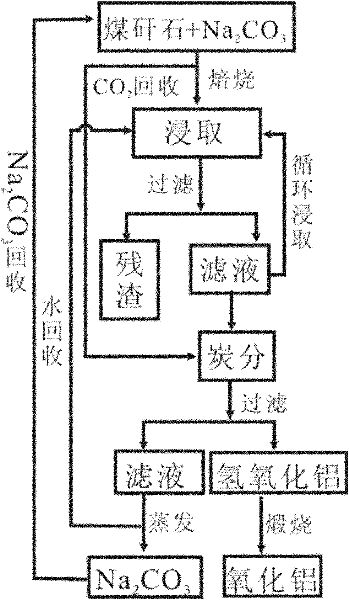

Method for extracting aluminum oxide from coal gangue

A technology of coal gangue and alumina, applied in alumina/aluminum hydroxide, solid waste removal, waste treatment and other directions, can solve the problems of inability to directly separate silicon and aluminum, poor quality of aluminum hydroxide, low sintering temperature, etc. Achieve the effect of alleviating the shortage of resources, short sintering time and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix the crushed coal gangue and solid sodium carbonate at a ratio of 1:0.6 and grind them into a 100-mesh mixed material.

[0035] (2) Calcining the mixed material obtained in step (1) at a temperature of 620° C. for 60 minutes to obtain roasted clinker. The roasted clinker is divided into several equal parts with the same quality for later use; during roasting, the roasting equipment is connected to the gas output pipe and connected to the carbon separation tank, and the recovered carbon dioxide gas is directly used for carbon separation.

[0036] (3) Add an appropriate amount of water to the first portion of roasted clinker, and make the solid-liquid mass ratio 1:6, and leaching for 50 minutes at a temperature of 10°C. After leaching, filter to obtain filter residue and filtrate respectively. After determination, the leaching rate of alumina in the filtrate is 70%, and the leaching rates of other components such as silicon dioxide and iron oxide are all zero.

...

Embodiment 2

[0044] (1) Mix the crushed coal gangue and solid sodium carbonate at a ratio of 1:2.5 and grind them into a 250-mesh mixed material.

[0045] (2) Calcining the mixed material obtained in step (1) at a temperature of 990° C. for 10 minutes to obtain roasted clinker. The roasted clinker is divided into several equal parts with the same quality for later use; during roasting, the roasting equipment is connected to the gas output pipe and connected to the carbon separation tank, and the recovered carbon dioxide gas is directly used for carbon separation.

[0046] (3) Add an appropriate amount of water to the first portion of roasted clinker, and make the solid-to-liquid mass ratio 1:120, and leaching at 85° C. for 5 minutes. After leaching, filter to obtain filter residue and filtrate respectively. After determination, the leaching rate of alumina in the filtrate is 75%, and the leaching rates of other components such as silicon dioxide and iron oxide are all zero.

[0047] Put ...

Embodiment 3

[0054] (1) Mix the crushed coal gangue and solid sodium carbonate at a ratio of 1:2.3 and grind them into a 150-mesh mixed material.

[0055] (2) Calcining the mixed material obtained in step (1) at a temperature of 720° C. for 50 minutes to obtain calcined clinker. The roasted clinker is divided into several equal parts with the same quality for later use; during roasting, the roasting equipment is connected to the gas output pipe and connected to the carbon separation tank, and the recovered carbon dioxide gas is directly used for carbon separation.

[0056] (3) Add appropriate amount of water to the first batch of roasted clinker, and make the solid-liquid mass ratio 1:15, and leaching for 40 minutes under the temperature condition of 20°C. After leaching, filter to obtain filter residue and filtrate respectively. After determination, the leaching rate of alumina in the filtrate was 79%, and the leaching rates of other components such as silicon dioxide and iron oxide were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com