Method for preparing nanometer Co-Fe prussian-blue complex-carbon nano tube composite hydrogen peroxide sensor

A carbon nanotube composite, Prussian blue technology is applied in the field of preparation of a new type of hydrogen peroxide sensor, which can solve the problems of high detection limit, low detection limit, and poor sensor sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

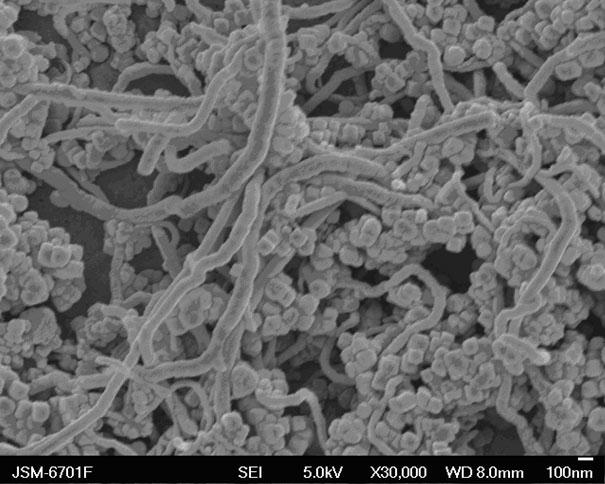

Image

Examples

Embodiment 1

[0031] (1) Preparation of Co-Fe Prussian blue complex nanoparticles: After adding 3.55 g of sodium 2-ethylhexyl succinate sulfonate to 20 mL (13.86 g) of isooctane (or cyclohexane) (ten Hexaalkyltrimethylammonium bromide or polyethylene glycol octylphenyl ether), then add 4.5336g to a concentration of 0.03mol L -1 CoCl 2 Solution, stirred until clear; use a micro-syringe to add dropwise 1.9426g concentration of 0.014mol L -1 K 3 Fe(CN) 6 and a concentration of 0.006 mol L -1 CsCl solution with a drop rate of 20 μL / min; magnetic stirring at constant temperature for 11 hours, aging for 11 hours; repeated centrifugation washing with ethanol aqueous solution and absolute ethanol to remove impurities, and finally dispersing the product with ethanol to obtain Co-Fe Prussian blue complex nano particle.

[0032] (2) Surface pretreatment of glassy carbon electrodes: First, immerse glassy carbon electrodes with a diameter of 3mm in dilute sulfuric acid to activate them, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com