Method for preparing polytetrafluoroethylene resin for coating

The technology of polytetrafluoroethylene and phase tetrafluoroethylene is applied in the field of preparation of polytetrafluoroethylene resin, which can solve the problems of ultra-fast polymerization reaction speed, decreased yield, and reduced crystallinity of copolymer, and achieves the promotion of uniform alternating reaction. , The effect of improving construction performance and eliminating performance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 66kg of mixed solvent of butyl acetate and 24kg of methyl isobutyl ketone, 44kg of vinyl acetate, 8kg of allyl alcohol, and 2.5kg of undecylenic acid into the polymerization reactor; cool the reactor to 15°C, and evacuate And replace with nitrogen 3 to 4 times;

[0033] 2) When the vacuum degree in the kettle reaches 0.095MPa, add gas-phase tetrafluoroethylene monomer until the pressure in the kettle rises by 0.03MPa (gauge pressure), and analyze the oxygen content. When the oxygen content in the kettle system is ≤ 30ppm, it is qualified; Azodiisobutyronitrile was dissolved in butyl acetate to make a dilute solution with a concentration of 4% by weight, and the above-mentioned solution was pumped into the reactor with a constant flow rate of 4L / h with a metering pump, and then the agitator was started;

[0034] 3) Raise the temperature and pressure of the reactor to the first constant point, that is, the temperature is 65±1°C, and the pressure is 0.9±0.05MPa (gau...

Embodiment 2

[0045] Add each polymerizable monomer according to the amount shown in Table 1, and carry out the polymerization reaction according to the preparation method of Example 1, wherein, during the polymerization process, the initiator is continuously added at a constant flow rate of 5 L / h. When the temperature and pressure of the reactor rise to the first constant point, the temperature is 55±1°C, and the pressure is 1.0±0.05MPa (gauge pressure); when the amount of additional tetrafluoroethylene monomer is consumed to about 1 / 3, the reactor The temperature and pressure rise to the second constant point, the temperature is 70±1°C, and the pressure is 1.5±0.05MPa (gauge pressure); when the amount of additional tetrafluoroethylene monomer is consumed to about 2 / 3, the temperature and pressure of the reactor Rising to the third constant point, the temperature is 80±1°C, the pressure is 2.0±0.05MPa (gauge pressure), when the amount of tetrafluoroethylene monomer added is the rated amount...

Embodiment 3

[0047] The polymerized monomers were added in the amounts shown in Table 1, and the preparation process was the same as in Example 1. The performance test of the prepared product was performed, and the results are shown in Table 1.

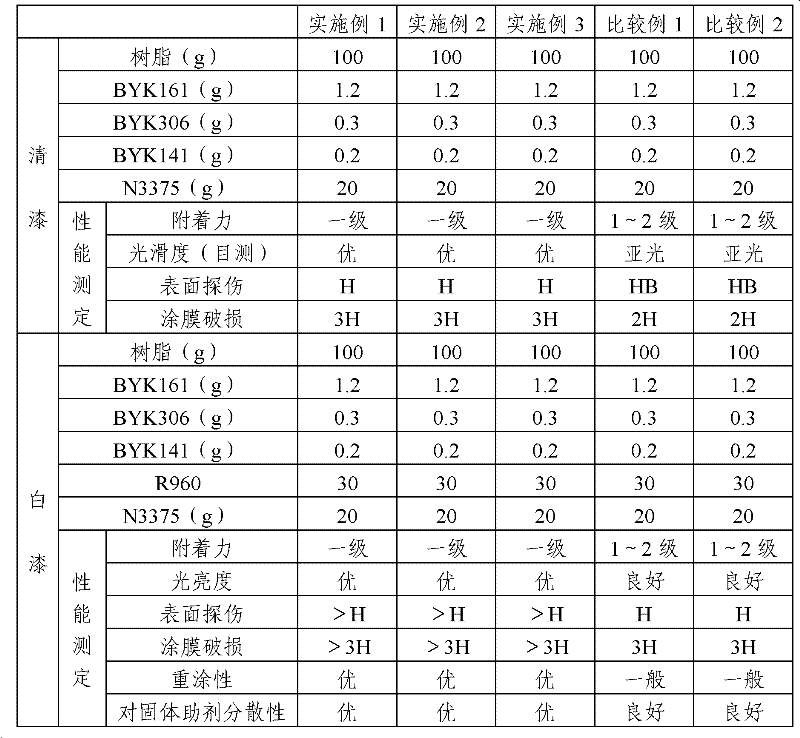

[0048] Table 1 Formula and performance test (unit: kg)

[0049]

[0050] As can be seen from Table 1, the polytetrafluoroethylene resin for coatings prepared by the method of the present invention is colorless and transparent in appearance, between 3 ± 0.5 in chroma, high in fluorine content, and excellent in solubility to solvents. According to the fluorine content of the resin, products with different fluorine content can be provided according to the market demand of different application fields of the resin, and the application development of the potential market can be broadened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com