Preparation method of polyethylene terephthalate-1,3-propanediol copolyester

A technology of polyethylene terephthalate and propylene glycol copolyester, applied in the field of producing polyethylene terephthalate-1, can solve the problem of low degree of polymerization and achieve high catalytic activity, high intrinsic viscosity, The effect of increased reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

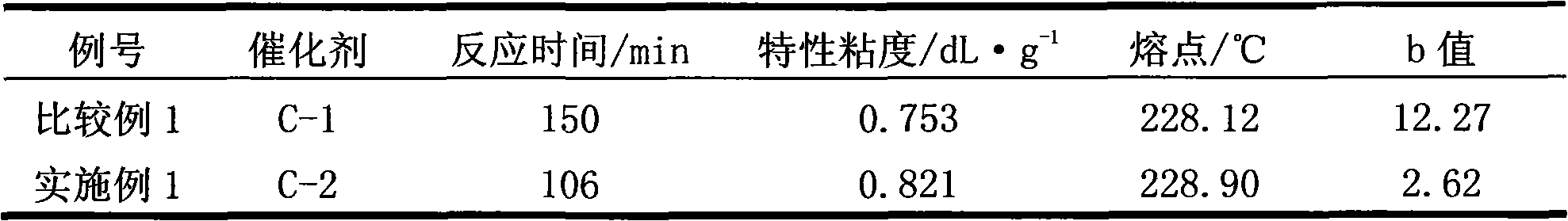

Examples

Embodiment 1

[0028] Into a 5L stainless steel reaction kettle equipped with nitrogen inlet, condensate outlet and stirrer, add 1000 grams of purified terephthalic acid (PTA), 575 grams of 1,3-propanediol (1,3-PDO), 85 grams of ethylene glycol Alcohol (EG), equivalent to 50ppm titanium n-butyl titanate, 60ppm cobalt cobalt acetate and 70ppm germanium germanium dioxide, then use nitrogen to pressurize to 0.2MPa, keep constant pressure, and the temperature in the reactor rises to 250°C , when the amount of by-product water distilled out in the reactor reaches the theoretical water output, the pressure in the still returns to normal pressure, then adds trimethyl phosphate equivalent to 60ppm phosphorus in the still, and vacuumizes the pressure in the polymerization still to Reduce to below 100Pa within 30 minutes, react under this pressure, control the final temperature of the reaction at 265-275°C, then use nitrogen to restore the reaction system to normal pressure, the polymer melt is cast an...

Embodiment 2

[0036] In a 5 L stainless steel reaction kettle equipped with nitrogen inlet, condensate outlet and stirrer, add 1000 g of purified terephthalic acid (PTA), 575 g of 1,3-propanediol (1,3-PDO), 85 g of ethyl Glycol (EG), make a slurry of n-butyl titanate or tetramethyl titanate equivalent to 25ppm titanium, cobalt nitrate 60ppm and germanium dioxide 70ppm germanium into the reaction kettle, and then pressurize with nitrogen To 0.2MPa, keep a constant pressure, the temperature inside the reactor rises to 250°C, when the by-product water distilled out of the reactor reaches the theoretical amount, the pressure inside the kettle returns to normal pressure, and titanium equivalent to 50ppm titanium is added into the kettle N-butyl acid or tetramethyl titanate, phosphorous acid of 60ppm phosphorus, vacuumize to reduce the pressure to below 100Pa within 20 minutes, maintain the vacuum for 130-140 minutes, and control the final reaction temperature at 265-275°C. Then use nitrogen to e...

Embodiment 3

[0038] In a 5 L stainless steel reaction kettle equipped with nitrogen inlet, condensate outlet and stirrer, add 1000 g of purified terephthalic acid (PTA), 575 g of 1,3-propanediol (1,3-PDO), 85 g of ethyl Glycol (EG), add tetrapropyl titanate or tetraisopropyl titanate equivalent to 20ppm titanium, cobalt phosphate 100ppm cobalt and germanium dioxide 110ppm germanium, then pressurize to 0.2MPa with nitrogen to maintain constant pressure , the temperature in the reactor rises to 250°C, and when the by-product water distilled out of the reactor reaches the theoretical amount, the pressure in the reactor returns to normal pressure, and tetrapropyl titanate or titanate equivalent to 50ppm titanium is added into the reactor Tetraisopropyl ester, 30ppm phosphorus ethyl methyl phosphate or phosphoric acid, vacuumize to reduce the pressure below 100Pa within 30 minutes, maintain this vacuum for 140 minutes, control the final reaction temperature at 265-275°C, and then eliminate it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com