Method for preparing antistatic laminated material from graphene

An antistatic layer, graphene technology, applied in the directions of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of reducing the mechanical properties of composite materials, antistatic particles falling off, poor processing performance, etc., to eliminate static electricity. Harm, the effect of improving the quality of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

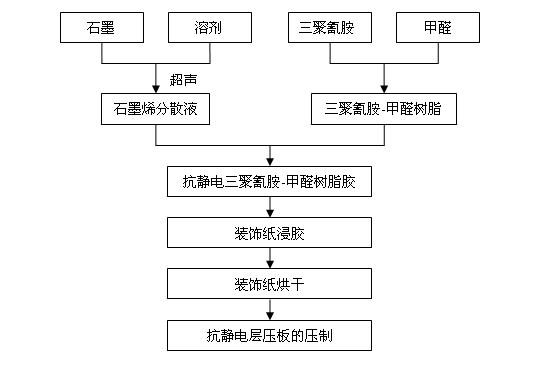

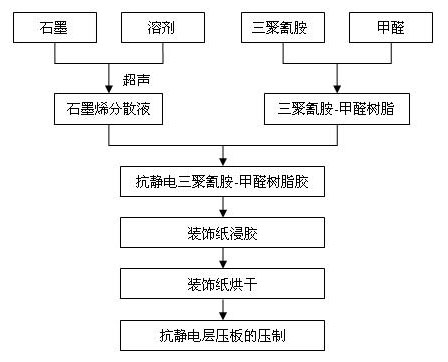

Image

Examples

Embodiment 1

[0024] (1) Preparation of graphene homogeneous dispersion

[0025] Add 0.5g of graphite powder into 40.0g of NMP, and ultrasonicate at 250w for 6h to prepare a homogeneous dispersion of graphene in NMP.

[0026] (2) Preparation of melamine-formaldehyde prepolymerized resin

[0027] Melamine and formaldehyde undergo polycondensation reaction at a molar ratio of 1:2.5 to form a precipitation ratio of 1:1 (slowly drop 1mL of resin product into 1mL of distilled water, if the mixture is slightly turbid, it means that the precipitation ratio reaches 1:1) Melamine-formaldehyde prepolymerized resin.

[0028] (3) Preparation of antistatic veneer

[0029] The 4.9g graphene homogeneous dispersion liquid described in step (1) (the thickness of graphene is 5 ~ 10nm, size is 100nm 2 ~100μm 2 ) and 10 g of melamine-formaldehyde prepolymerized resin are mixed directly, and the antistatic melamine-formaldehyde prepolymerized resin glue is prepared by stirring evenly. Immerse a 3.0cm×3.0cm...

Embodiment 2

[0031] (1) Preparation of graphene homogeneous dispersion

[0032] Add 0.5 g of natural flake graphite into 40.0 g of NMP, and ultrasonicate at 250 w for 6 h to prepare a homogeneous dispersion of graphene in NMP.

[0033] (2) Preparation of melamine-formaldehyde prepolymerized resin

[0034] Melamine and formaldehyde undergo polycondensation reaction at a molar ratio of 1:2.5 to form a precipitation ratio of 1:1 (slowly drop 1mL of resin product into 1mL of distilled water, if the mixture is slightly turbid, it means that the precipitation ratio reaches 1:1) Melamine-formaldehyde prepolymerized resin.

[0035] (3) Preparation of antistatic veneer

[0036] The 4.9g graphene homogeneous dispersion liquid described in step (1) (the thickness of graphene is 5 ~ 10nm, size is 100nm 2 ~100μm 2 ) and 10 g of melamine-formaldehyde prepolymerized resin are mixed directly, and the antistatic melamine-formaldehyde prepolymerized resin glue is prepared by stirring evenly. Immerse a ...

Embodiment 3

[0038] (1) Preparation of graphene homogeneous dispersion

[0039] Add 0.4g of graphite powder into 40.0g of NMP, and ultrasonicate at 250w for 6h to prepare a homogeneous dispersion of graphene in NMP.

[0040] (2) Preparation of melamine-formaldehyde prepolymerized resin

[0041] Melamine and formaldehyde undergo polycondensation reaction at a molar ratio of 1:2.5 to form a precipitation ratio of 1:1 (slowly drop 1mL of resin product into 1mL of distilled water, if the mixture is slightly turbid, it means that the precipitation ratio reaches 1:1) Melamine-formaldehyde prepolymerized resin.

[0042] (3) Preparation of antistatic veneer

[0043] The 6.1g graphene homogeneous dispersion liquid described in step (1) (the thickness of graphene is 5 ~ 10nm, the size is 100nm 2 ~100μm 2 ) and 10 g of melamine-formaldehyde prepolymerized resin are mixed directly, and the antistatic melamine-formaldehyde prepolymerized resin glue is prepared by stirring evenly. Immerse a 3.0cm×3.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com