No-clean copper-aluminum sheet stamping oil

A stamping oil and no-cleaning technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as increased production costs of cleaning equipment, reduced stamping oil safety, and environmental pollution of cleaning agents, achieving excellent metal protection and accelerating static electricity Good effect on leakage and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

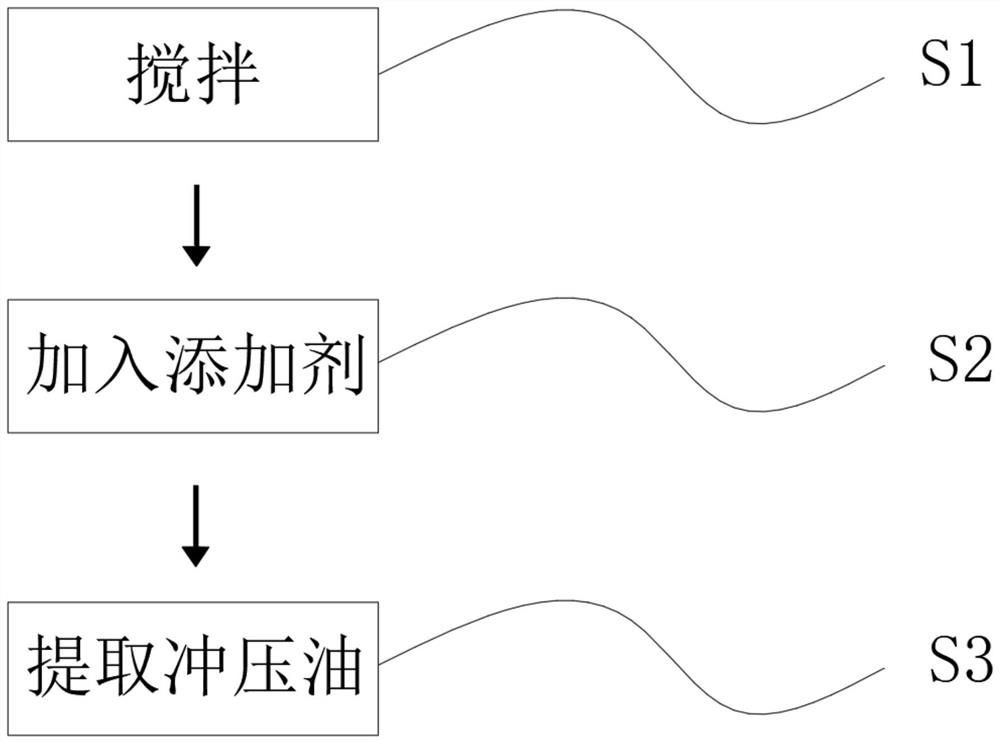

[0022] Example 1, please refer to figure 1 , the present invention provides a technical solution: a no-clean copper-aluminum sheet stamping oil, the preparation material of the no-clean copper-aluminum sheet stamping oil is alkane solvent base oil, lubricity additive, metal deactivator, Antioxidant, anti-corrosion and bactericide, diluent and antistatic additive, and the weight ratio of each material is as follows: alkane solvent base oil is 99.94%, and carbon chain length is 12 at the same time, the isoparaffin solvent that distillation range is 170, lubricating 0.05% for non-toxic additives, 0.01% for metal deactivators, 1.5% for antioxidants, 2% for antiseptics and bactericides, 3.5% for diluents, and 3% for antistatic additives. Quick-drying copper-aluminum stamping oil sold in the market, this kind of stamping oil reduces the kinematic viscosity, and at the same time has double the maximum non-jamming load, the closed flash value is lower, and the acid value and copper co...

Embodiment 2

[0034] Example 2, please refer to figure 1 , the present invention provides a technical solution: a no-clean copper-aluminum sheet stamping oil, the preparation material of the no-clean copper-aluminum sheet stamping oil is alkane solvent base oil, lubricity additive, metal deactivator, Antioxidant, anti-corrosion and bactericide, diluent and antistatic additive, and the weight ratio of each material is as follows: alkane solvent base oil is 99.87%, and the carbon chain length is 8 at the same time, the isoparaffin solvent that distillation range is 180, lubricating 0.1% for additives, 0.03% for metal deactivators, 2% for antioxidants, 1.5% for antiseptics, 5% for diluents, and 3.5% for antistatic additives. The quick-drying copper-aluminum stamping oil sold on the market, this kind of stamping oil reduces the kinematic viscosity, but the value of the kinematic viscosity is higher than the value in the first embodiment, and has a higher maximum non-jamming load than the first ...

Embodiment 3

[0046] Embodiment three, please refer to figure 1 , the present invention provides a technical solution: a no-clean copper-aluminum sheet stamping oil, the preparation material of the no-clean copper-aluminum sheet stamping oil is alkane solvent base oil, lubricity additive, metal deactivator, Antioxidant, anticorrosion and bactericide, diluent and antistatic additive, and the weight ratio of each material is as follows: alkane solvent base oil is 99.8%, and carbon chain length is 12 at the same time, the isoparaffin solvent that distillation range is 165, lubricating 0.15% for additives, 0.05% for metal deactivators, 1% for antioxidants, 2% for antiseptics, 3.5% for diluents, and 4.5% for antistatic additives. In the quick-drying copper-aluminum stamping oil sold on the market, this stamping oil has reduced kinematic viscosity, but the numerical value of kinematic viscosity will be higher than the numerical value in embodiment one and embodiment two, has higher than embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com