Surface protection film for processing device with uneven structure on surface

A surface protection film and uneven technology, applied in the direction of film/sheet adhesive, non-polymer organic compound adhesive, adhesive, etc., can solve the problems of damage to the concave and convex surface of the device, insufficient strength of the protective film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

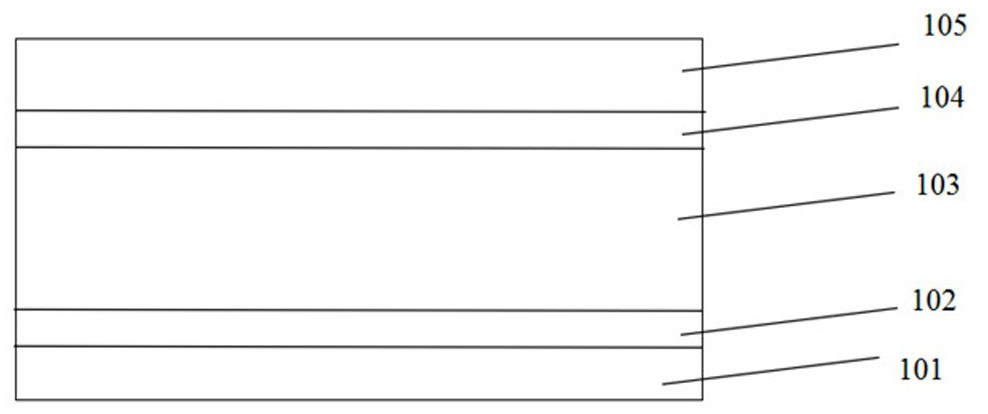

Image

Examples

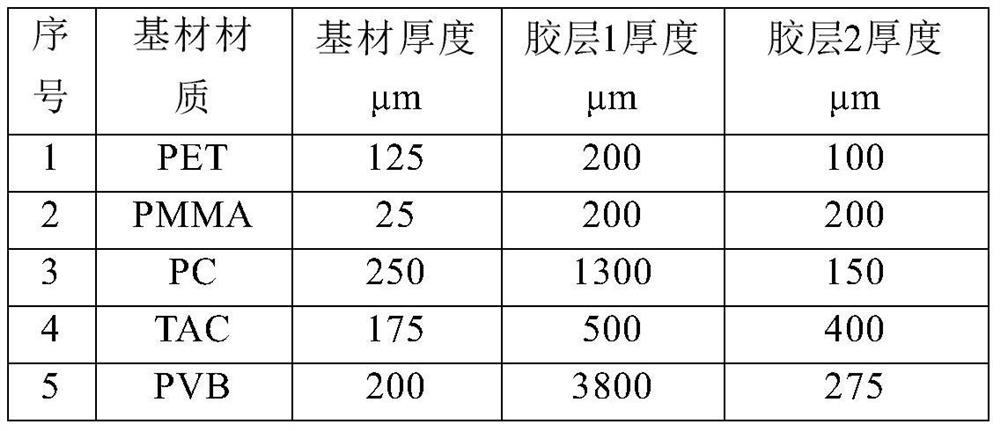

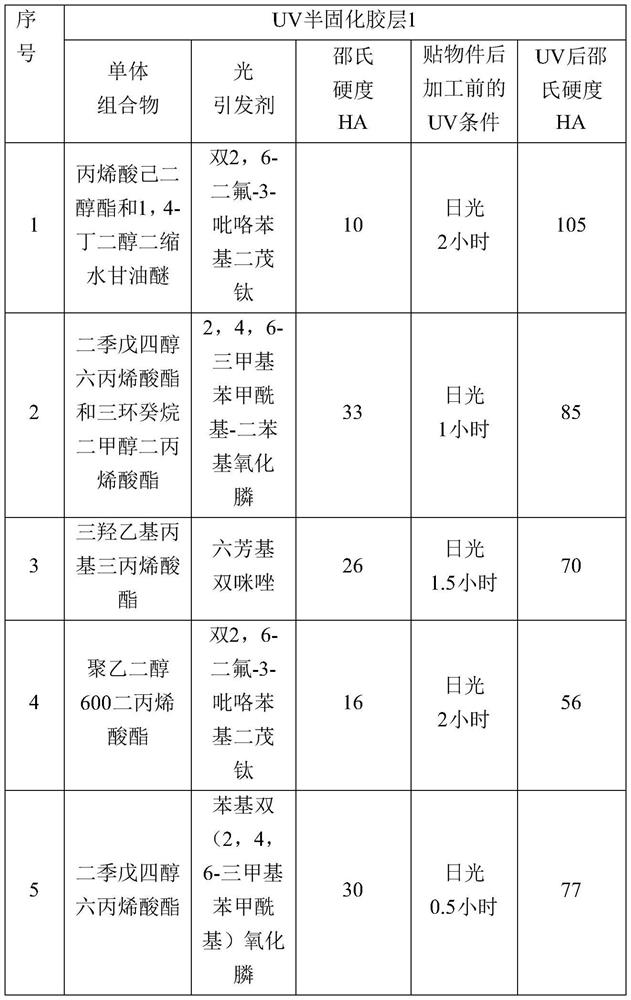

Embodiment 1

[0028] On one side of the PET substrate layer 101 with a thickness of 125 μm, a UV adhesive layer A with a thickness of 200 μm is coated. The adhesive layer A is composed of hexanediol acrylate and 1,4-butanediol diglycidyl ether, and the added content is 0.1% w / w's photoinitiator bis-2,6-difluoro-3-pyrrole phenyl titanocene forms a UV semi-cured adhesive layer A by UV irradiation, with a Shore hardness of 10HA. Then on the UV semi-cured adhesive layer A, a UV adhesive layer B with a thickness of 100 μm is coated. The adhesive layer B is composed of three (2-hydroxyethyl) isocyanurate diacrylate and isocyanate, and the added content is 0.01% w / The photoinitiator of w, 1-hydroxycyclohexyl phenyl ketone, forms UV semi-cured adhesive layer B through heating and subsequent curing, with a viscosity of 870gf / inch. Paste the protective film on the uneven surface of the device to be processed, let the adhesive layer fill the uneven surface of the device to be processed, and use sunl...

Embodiment 2

[0030] On one side of the PMMA substrate layer 101 with a thickness of 25 μm, a UV adhesive layer A with a thickness of 200 μm is coated, and the adhesive layer A is composed of dipentaerythritol hexaacrylate and tricyclodecane dimethanol diacrylate, and adding a content of 0.2% w / w Photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide forms UV semi-cured adhesive layer A by UV irradiation, Shore hardness 33HA. Then on the UV semi-cured adhesive layer A, a UV adhesive layer B with a thickness of 200 μm is coated, and the adhesive layer B is composed of tetraglycidyl benzyl ethane, and a photoinitiator benzophenone with a content of 0.02% w / w is added, UV semi-cured adhesive layer B is formed by UV irradiation, with a viscosity of 2100gf / inch. Paste the protective film on the uneven surface of the device with uneven structure on the surface, let the adhesive layer fill the uneven surface of the device to be processed, and use sunlight to irradiate the surface of the pro...

Embodiment 3

[0032] On one side of the transparent PC substrate layer 101 with a thickness of 250 μm, a UV adhesive layer A with a thickness of 1300 μm is coated. The adhesive layer A is composed of trihydroxyethylpropyl triacrylate, and a photoinitiator hexaaryl with a content of 0.4% w / w is added. Based on bisimidazole, UV semi-cured adhesive layer A is formed by UV irradiation, and the Shore hardness is 26HA. Then, on the UV semi-cured adhesive layer A, a UV adhesive layer B with a thickness of 150 μm is coated. The adhesive layer B is composed of polyethylene glycol 200 dimethacrylate, and a photoinitiator diphenylbenzene with a content of 0.03% w / w is added. Ketone, form UV semi-cured adhesive layer B by UV irradiation, viscosity 1600gf / inch. Paste the protective film on the uneven surface of the device with uneven structure on the surface, let the adhesive layer fill the uneven surface of the device to be processed, and use sunlight to irradiate the surface of the protective film for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com