All-solid-state carbonate ion selective electrode and manufacture method of all-solid-state carbonate ion selective electrode

A carbonate ion, all-solid-state technology, used in material analysis, measuring devices, instruments, etc. by electromagnetic means, can solve problems such as affecting the equilibrium concentration of carbonate ions in water bodies, and avoid changes in carbonate ion concentration and small volume. , the effect of good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

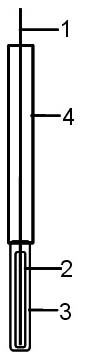

[0017] The steps of the preparation method of the all-solid-state carbonate ion selective electrode are as follows:

[0018] 1) Immerse the lower part of the metal wire 1 into the corundum sand suspension, use ultrasonic vibration to polish for 10-15 minutes, soak in 0.5-2 mol / L dilute HCl solution for 3-5 minutes, rinse with deionized water, and use surfactant Aqueous solution cleaning, drying at 60-80°C, the suspension of corundum sand is a suspension containing 0.2-1.2 grams of corundum sand per 50 milliliters of deionized water;

[0019] 2) Prepare conductive polymer and deionized water volume ratio of 1.0-5.0% suspension, add 0.01-0.1% treatment agent and 1.5-5.0% sodium carboxymethylcellulose or hydroxyethyl cellulose Sodium cellulose is formulated into an electrolyte slurry, and the electrolyte slurry is coated on the surface of the metal wire treated in step 1) to form a solid electrolyte layer 2;

[0020] 3) Dissolve carbonate ionophores, lipophilic macromolecules, a...

Embodiment 1

[0024] 1) Dip one end of a gold wire with a diameter of 0.2 mm into a corundum sand suspension with a mass fraction of 1%, use ultrasonic vibration for 15 minutes, soak in 1 mol / L dilute HCl solution for 5 minutes, rinse with deionized water and use 0.3 % sodium carboxymethyl cellulose solution to clean the gold wire, and place it in an oven to dry at 60°C;

[0025] 2) Disperse polyoxyethylene thiophene / polystyrene sulfonic acid in water to form a 1% suspension, add 0.03% polyethylene glycol isooctyl ether and 2% carboxymethyl fiber to the suspension Sodium plain or hydroxyethyl cellulose sodium is formulated into electrolyte slurry, which is coated on the surface of the pretreated gold wire to form a solid electrolyte layer with a thickness of about 15 microns;

[0026] 3) Add 16 mg of N,N-dioctyl-3α,12α-bis(4-trifluoroacetylbenzoyl)-5?-deoxycholic acid-24-amide, 5 mg of tri-dodecyl After mixing methylammonium chloride and 90 mg of nitrophenyl octyl ether, shake and mix for ...

Embodiment 2

[0028] 1) Dip one end of a gold wire with a diameter of 0.25mm into corundum sand suspension with a mass fraction of 2%, use ultrasonic vibration for 15 minutes, soak in 1 mol / L dilute HCl solution for 5 minutes, rinse with deionized water and use 0.3 % sodium carboxymethyl cellulose solution to clean the gold wire, and place it in an oven to dry at 80°C;

[0029] 2) Disperse polyoxyethylene thiophene / polystyrene sulfonic acid in water to form a 1% suspension, add 0.05% polyethylene glycol isooctyl ether and 3.0% carboxymethyl fiber to the suspension Sodium plain or hydroxyethyl cellulose sodium is formulated into electrolyte slurry, which is coated on the surface of the pretreated gold wire to form a solid electrolyte layer with a thickness of about 15 microns;

[0030]3) Add 17 mg of N,N-dioctyl-3α,12α-bis(4-trifluoroacetylbenzoyl)-5?-deoxycholic acid-24-amide, 3 mg of tri-dodecyl After mixing methylammonium chloride and 93 mg of bis(2-ethylhexyl) adipic acid, shake and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com