Red fluorescent material and preparation method thereof

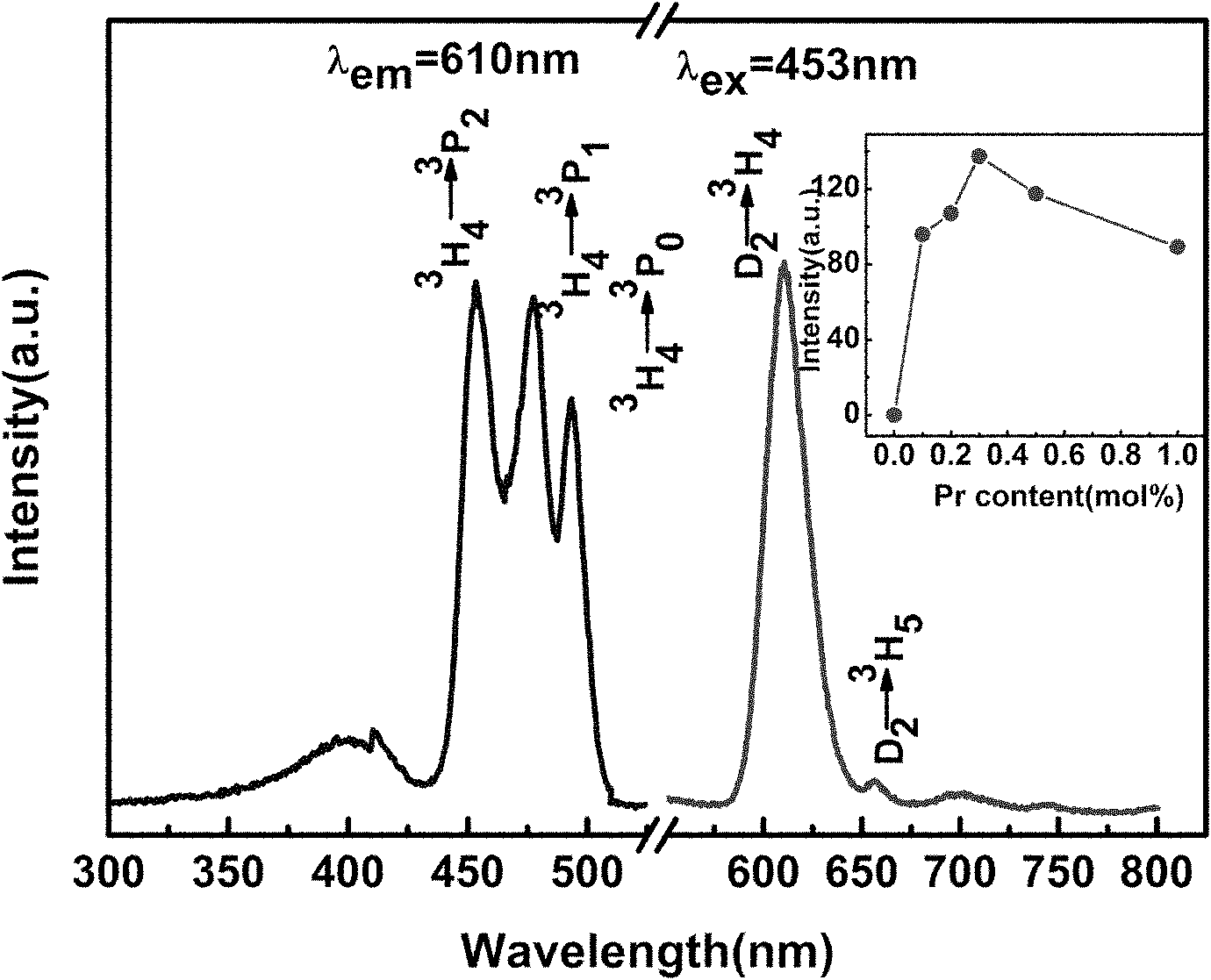

A technology excited by red fluorescence and blue light, which is applied in the field of red fluorescent materials and preparation, can solve the problems of easy deliquescence, poor stability, low efficiency, etc., and achieve the effect of not easy deliquescence and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare x=0.003 (Bi 0.5 Na 0.5 ) 1-x PR x TiO 3 material, namely (Bi 0.5 Na 0.5 ) 0.997 PR 0.003 TiO 3 . Select raw material Na 2 CO 3 、Pr 6 o 11 、 Bi2 o 3 and TiO 2 , according to (Bi 0.5 Na 0.5 ) 1-x PR x TiO 3 Weigh the selected raw materials in the proportion of corresponding elements, Na 2 CO 3 =2.6957g, Pr 6 o 11 =0.0516g, Bi 2 o 3 = 12.9045g and TiO 2 =7.9980g, after mixing the raw materials weighed, put into the ball mill jar and add dehydrated alcohol and zirconia balls to ball mill for 24 hours on the ball mill, and obtain the ball mill powder after discharging and drying with dehydrated alcohol, wherein dehydrated alcohol and The mass ratio of the raw material mixture is 3:1, and the mass ratio of the zirconia balls to the raw material mixture is 1.5:1. Put the ball mill powder in an alumina crucible for pre-burning, the pre-burning temperature is 850°C, the heating rate is 3°C / min, keep warm for 4 hours and cool naturally to get th...

Embodiment 2

[0034] Preparation (Bi 0.5 Na 0.5 ) 0.999 PR 0.001 TiO 3 , (Bi 0.5 Na 0.5 ) 0.998 PR 0.002 TiO 3 , (Bi 0.5 Na 0.5 ) 0.995 PR 0.005 TiO 3 and (Bi 0.5 Na 0.5 ) / 0.99 PR 0.01 TiO 3 . Select raw material Na 2 CO 3 、Pr 6 o 11 、 Bi 2 o 3 and TiO 2 , according to the chemical expression (Bi 0.5 Na 0.5 ) 0.999 PR 0.001 TiO 3 , (Bi 0.5 Na 0.5 ) 0.998 PR 0.002 TiO 3 , (Bi 0.5 Na 0.5 ) 0.995 PR 0.005 TiO 3 and (Bi 0.5 Na 0.5 ) 0.99 PR 0.01 TiO 3 Weigh the selected raw materials respectively, mix the weighed raw materials respectively, put them into a ball mill tank, add absolute ethanol and zirconia balls, and ball mill on the ball mill for 24 hours, discharge and dry with absolute ethanol, and then respectively Ball milling powders Al, A2, A3 and A4 were obtained, wherein the mass ratio of absolute ethanol to the raw material mixture was 2:1, and the mass ratio of zirconia balls to the raw material mixture was 1:1. The ball mill powders A1, ...

Embodiment 3

[0039] Preparation material (Bi 0.5 Na 0.5 ) 0.99 Eu 0.01 TiO 3 . Select raw material Na 2 CO 3 、Eu 2 o 3 、 Bi 2 o 3 and TiO 2 , according to (Bi 0.5 Na 0.5 ) 0.99 Eu 0.01 TiO 3 The ratio of the corresponding elements in Weigh the selected raw materials, Na 2 CO 3 =2.6768g, Eu 2 o 3 =0.1760g, Bi 2 o 3 = 11.6490g and TiO 2=7.9980g, after mixing the raw materials weighed, put into the ball mill jar and add dehydrated alcohol and zirconia balls to ball mill for 24 hours on the ball mill, and obtain the ball mill powder after discharging and drying with dehydrated alcohol, wherein dehydrated alcohol and The mass ratio of the raw material mixture is 1:1, and the mass ratio of the zirconia balls to the raw material mixture is 1.5:1. Put the ball mill powder in an alumina crucible for pre-burning, the pre-burning temperature is 750°C, the heating rate is 3°C / min, keep warm for 6 hours and cool naturally to get the pre-fired powder, grind the pre-fired powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com