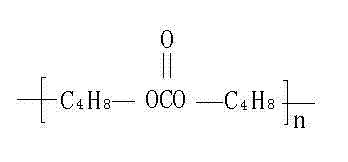

Biodegradable polycarbonate butylene terephthalate composite material and preparation method of biodegradable polycarbonate butylene terephthalate composite material

The technology of polybutylene carbonate and polybutylene carbonate is applied in the field of biodegradable polybutylene carbonate type composite material and its preparation, and can solve the problem of no light transfer, low melt strength and film brittleness. Large and other problems, to achieve good light conversion effect, high melt strength, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh each component according to the following parts by weight: PBC: 50.0, PLA: 36.0, compound type rare earth β nucleating agent, that is, rare earth composite nucleating agent (nano cerium oxide: nano europium oxide 65:35) 1.0, cage octamer Anilinomethylsilsesquioxane: 1.0, Polyethylene Glycol: 5.0, Butylene Dibutyltin: 2.5, Bisphenol A: 0.5, Stearic Acid: 0.7, Silicon Dioxide: 1.0, Malonic Acid: 0.05, Calcium Carbonate: 4.0.

[0034] Preparation steps and conditions are:

[0035] Weigh the matrix resin in proportion, dry it in an oven at 30°C for 6 hours in advance, and mix the weighed nano-cerium oxide and nano-europium oxide evenly in proportion, then put the baked matrix resin into the high-speed mixer, and start to mix at a low speed. Stir, while stirring, add the weighed rare earth composite nucleating agent, dispersant, plasticizer, heat-resistant stabilizer, antioxidant, lubricant, anti-blocking agent, biodegradation accelerator and filler in turn, and stir ...

Embodiment 2

[0040]Weigh each component according to the following parts by weight: PBC: 55.0, polycaprolactic acid PCL: 30.0, compound type rare earth β nucleating agent, that is, rare earth composite nucleating agent (nano cerium oxide: nano europium oxide 60:40): 1.5 , Cage octapolyaniline methyl silsesquioxane: 0.5, polypropylene glycol adipate: 5.0, zinc oxide: 2.5, ethyl phosphite: 0.5, stearic acid: 0.7, silicon dioxide: 1.0, propane Diacid: 0.05, calcium carbonate: 4.0;

[0041] See Example 1 for the preparation steps and conditions.

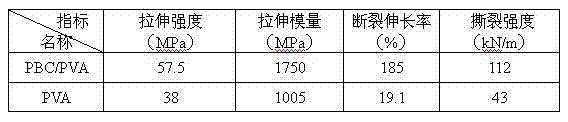

[0042] The performance comparison of the obtained film products is shown in Table 2.

[0043] Table 2:

Embodiment 3

[0045] Weigh each component according to the following parts by weight: PBC: 50.0, PBS: 35.0, compound type rare earth β nucleating agent, that is, rare earth composite nucleating agent (nano cerium oxide: nano europium oxide 70:30): 1.0, cage type eight Polyaniline methyl silsesquioxane: 0.5, epoxy soybean oil: 10.0, calcium stearate: 3.0, ethyl phosphite: 0.5, stearic acid: 1.0, silicon dioxide: 1.0, oxalic acid: 0.05, white Carbon black: 4.0;

[0046] See Example 1 for the preparation steps and conditions.

[0047] The performance comparison of the obtained film products is shown in Table 3.

[0048] table 3:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com