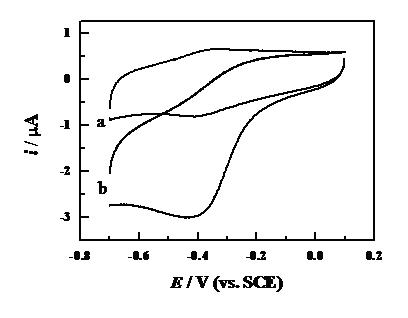

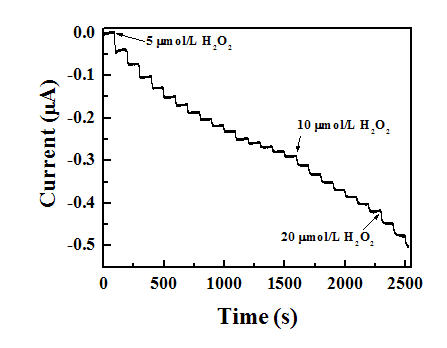

Method for testing hydrogen peroxide in cell based on horseradish peroxidase-attapulgite nanometer composite material

A technology of horseradish peroxidase and nanocomposite materials, which is applied in the fields of biosensing and cell electrochemistry, can solve the problems of being easily decomposed by microorganisms, the loss of biological activity of proteins, and the loss of original conformation, etc., to achieve good electrochemistry Chemical properties, low detection limit, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Grind 10 g of attapulgite in a grinder for 2 hours at a speed of 800 rpm; weigh 1 g of attapulgite ground, put it into 100 mL of ultrapure water for ultrasonic dispersion for 2 hours, and centrifuge it in a high-speed centrifuge ( 5000 rpm), washed the settled attapulgite with deionized water; repeated ultrasonic dispersion and centrifugation three times, and dried the washed attapulgite at 80 °C for 12 h to obtain purified attapulgite.

[0031] Add 0.5 mg of purified attapulgite into 1 mL of 0.1 mol / LPBS (pH 7.4) solution, and disperse ultrasonically for 0.5–2 hours to obtain a 0.5 mg / mL attapulgite dispersion; mix the attapulgite suspension with an equal volume Mix HRP in PBS (1 mg / mL, pH 7.4) and stir continuously at 4°C for 0.5 h. The mixture was centrifuged at 18,000 rpm for 30 min, and washed thoroughly with secondary water three times to remove the HRP molecules that were not firmly adsorbed, and the material was dried in a vacuum desiccator to obtain the HRP-Att...

Embodiment 2

[0034] The attapulgite purification method is the same as in Example 1. Add 2 mg of purified attapulgite into 1 mL of 0.1 mol / LPBS (pH 7.4) solution, and disperse ultrasonically for 0.5–2 hours to obtain a 2 mg / mL attapulgite dispersion; mix the attapulgite suspension with an equal volume of HRP PBS solution (5 mg / mL, pH 7.4) was mixed and stirred continuously at 4°C for 1 hour. The mixture was centrifuged at 10,000 rpm for 20 min, and washed thoroughly with secondary water three times to remove the HRP molecules that were not firmly adsorbed, and the material was dried in a vacuum desiccator to obtain the HRP-Attapulgite complex.

[0035] Glassy carbon electrodes (GC, 3 mm in diameter) were coated with No. 6 sandpaper, 0.3 μm and 0.05 μm Al 2 o 3 Polish to a mirror surface, then ultrasonically clean in ultrapure water for 30 seconds, and dry for use. Weigh 1 mg of HRP–Attapulgite complex and disperse it in 1 mL of 0.1 mol / L PBS (pH 7.4) solution, use a microsampler to tak...

Embodiment 3

[0037] The attapulgite purification method is the same as in Example 1. Add 5 mg of purified attapulgite into 1 mL of 0.1 mol / L PBS (pH 7.4) solution, and ultrasonically disperse for 0.5–2 hours to obtain a 5 mg / mL attapulgite dispersion; mix the attapulgite suspension with an equal volume of A solution of HRP in PBS (10 mg / mL, pH 7.4) was mixed and stirred continuously for 1 hour at 4 °C. The mixture was centrifuged at 5000 rpm for 15 min, and washed thoroughly with secondary water three times to remove the HRP molecules that were not firmly adsorbed, and the material was dried in a vacuum desiccator to obtain the HRP-Attapulgite complex.

[0038] Glassy carbon electrodes (GC, 3 mm in diameter) were coated with No. 6 sandpaper, 0.3 μm and 0.05 μm Al 2 o 3 Polish to a mirror surface, then ultrasonically clean in ultrapure water for 30 seconds, and dry for use. Weigh 1 mg of HRP–Attapulgite complex and disperse it in 1 mL of 0.1 mol / L PBS (pH 7.4) solution, use a microsampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com