Preparation method of sodium cantharidate

A technology of sodium cantharidinium and cantharidinium, which is applied in the direction of organic chemistry, etc., can solve problems such as long production cycle, and achieve the effects of shortening production cycle, reducing solvent usage, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

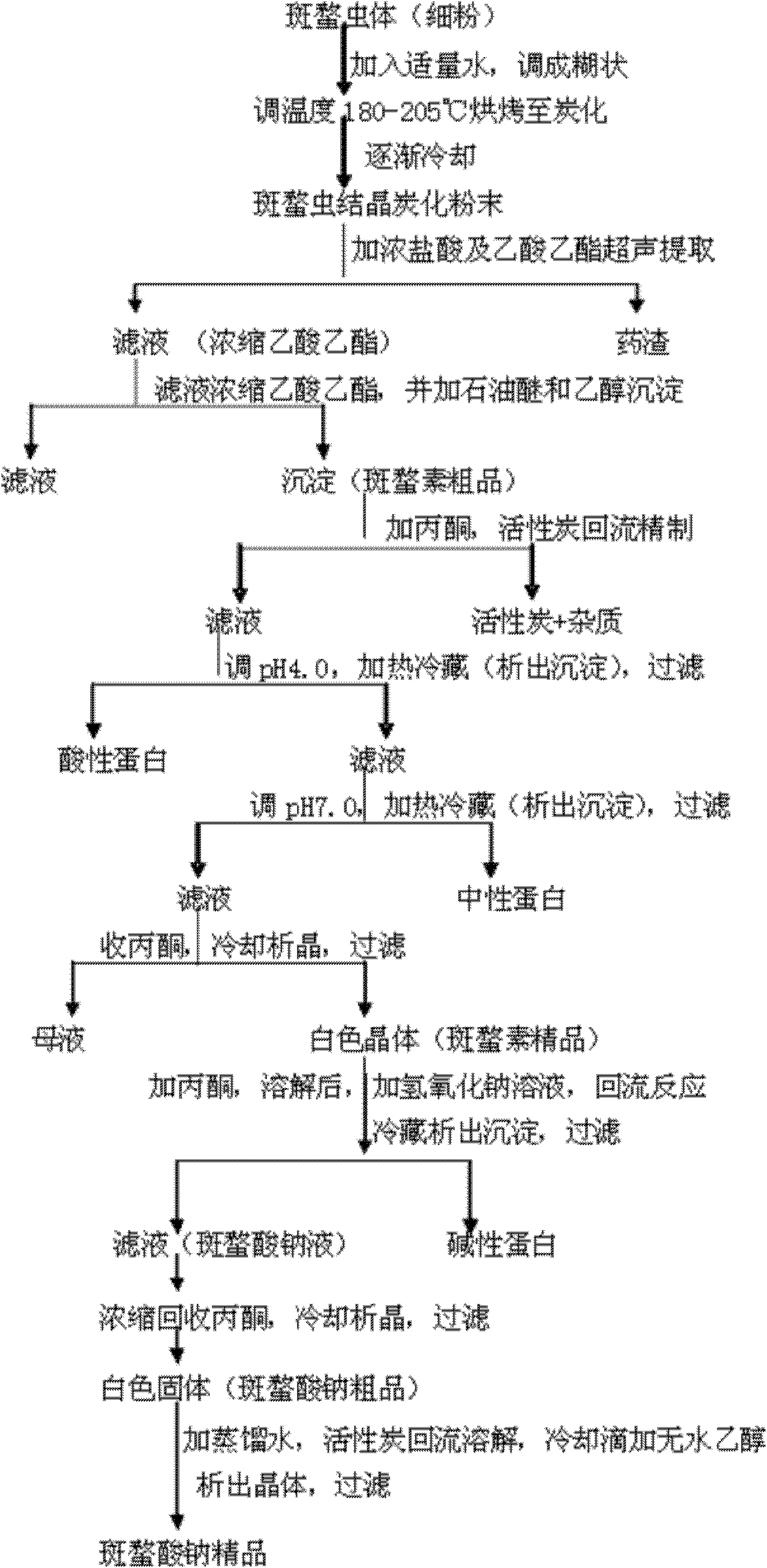

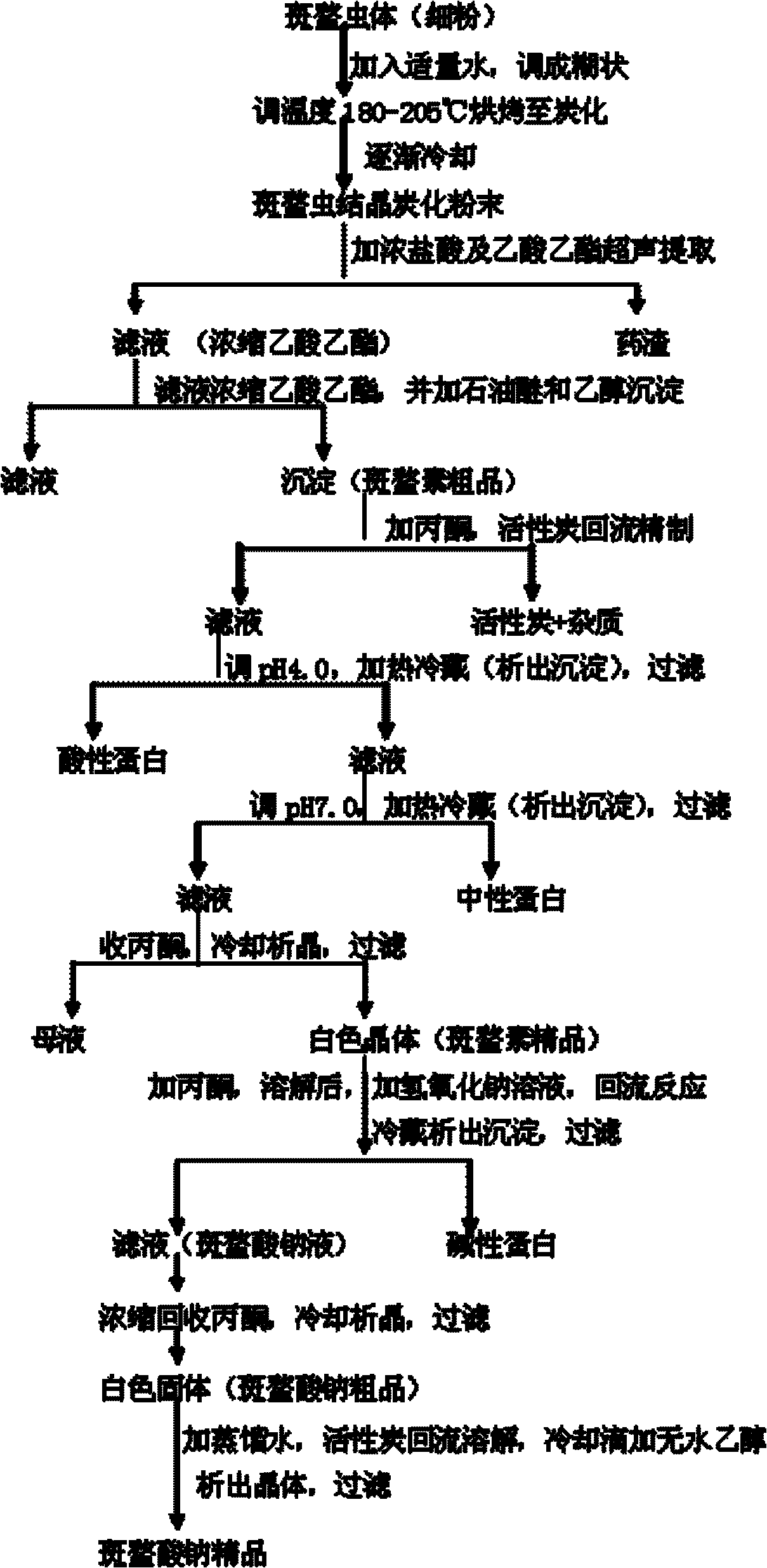

[0019] Example. Such as figure 1 As shown, the preparation method of the present invention comprises the following steps: (1) high-temperature carbonization of the cantharidin: the cantharidin is picked, and the sundries are removed, then dried and ground into fine powder, so that the fineness of the cantharidin powder is between 40 and 60 mesh, according to the volume ratio of cantharidin powder: water = 1:1, add water to the cantharidin powder and stir to form a paste, put it in an electric oven, adjust the temperature to 205°C, and gradually bake until the cantharidin is charred ; Take it out and gradually cool until white crystals are precipitated in the carbonized powder, and crushed to obtain the carbonized powder of cantharidin crystals.

[0020] (2) Weigh 1kg of cantharidin crystalline carbonized powder, put it in a 3000ml round bottom flask, add 200ml of concentrated hydrochloric acid, then add 3L of ethyl acetate, perform ultrasonic extraction at 60°C for 2 times, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com