Method for synthesizing porous microsphere material containing NaY zeolite by waste FCC (fluid catalytic cracking) catalyst

A technology of porous microspheres and spent catalysts, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of saving raw materials, large specific surface area, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

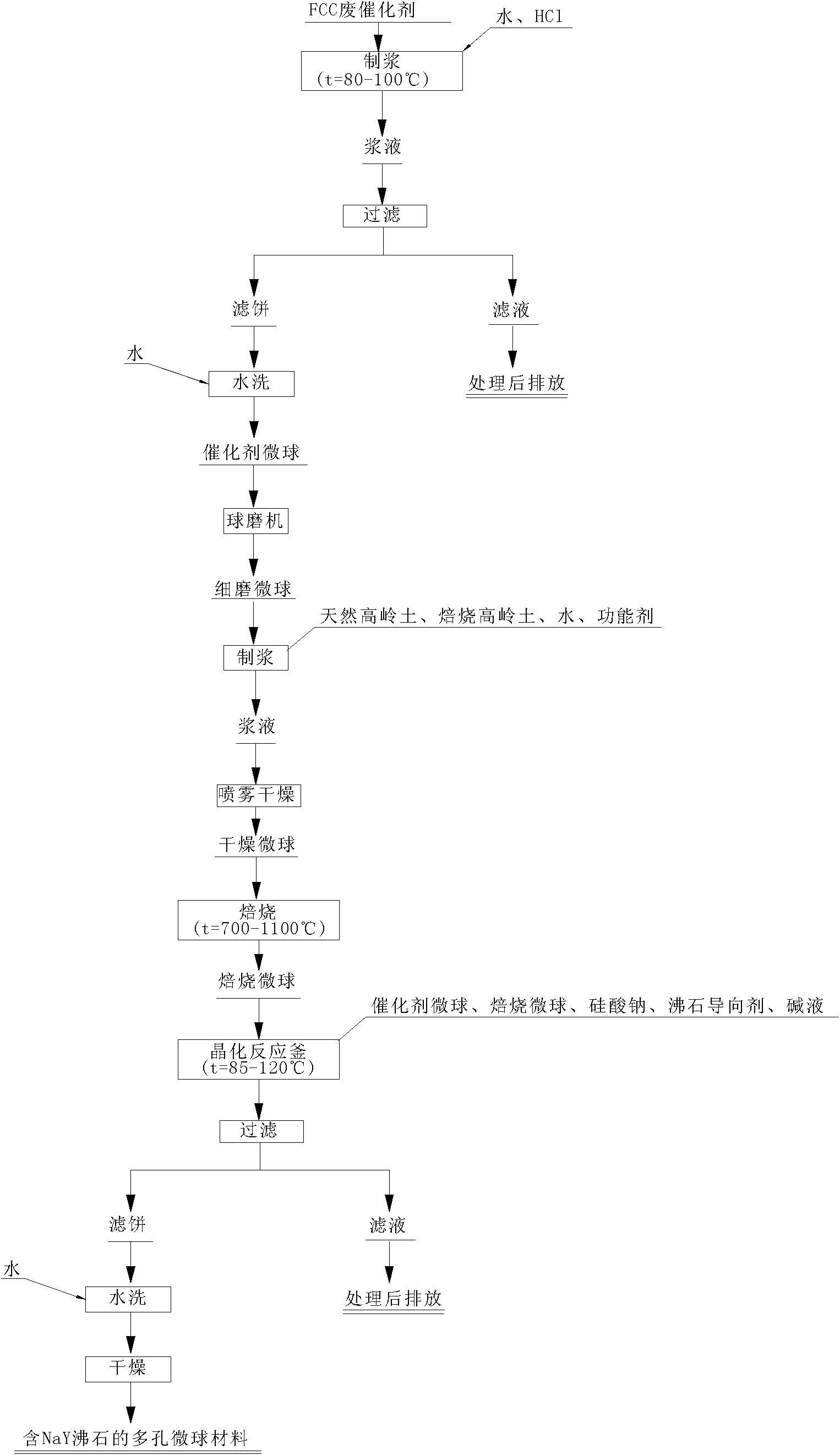

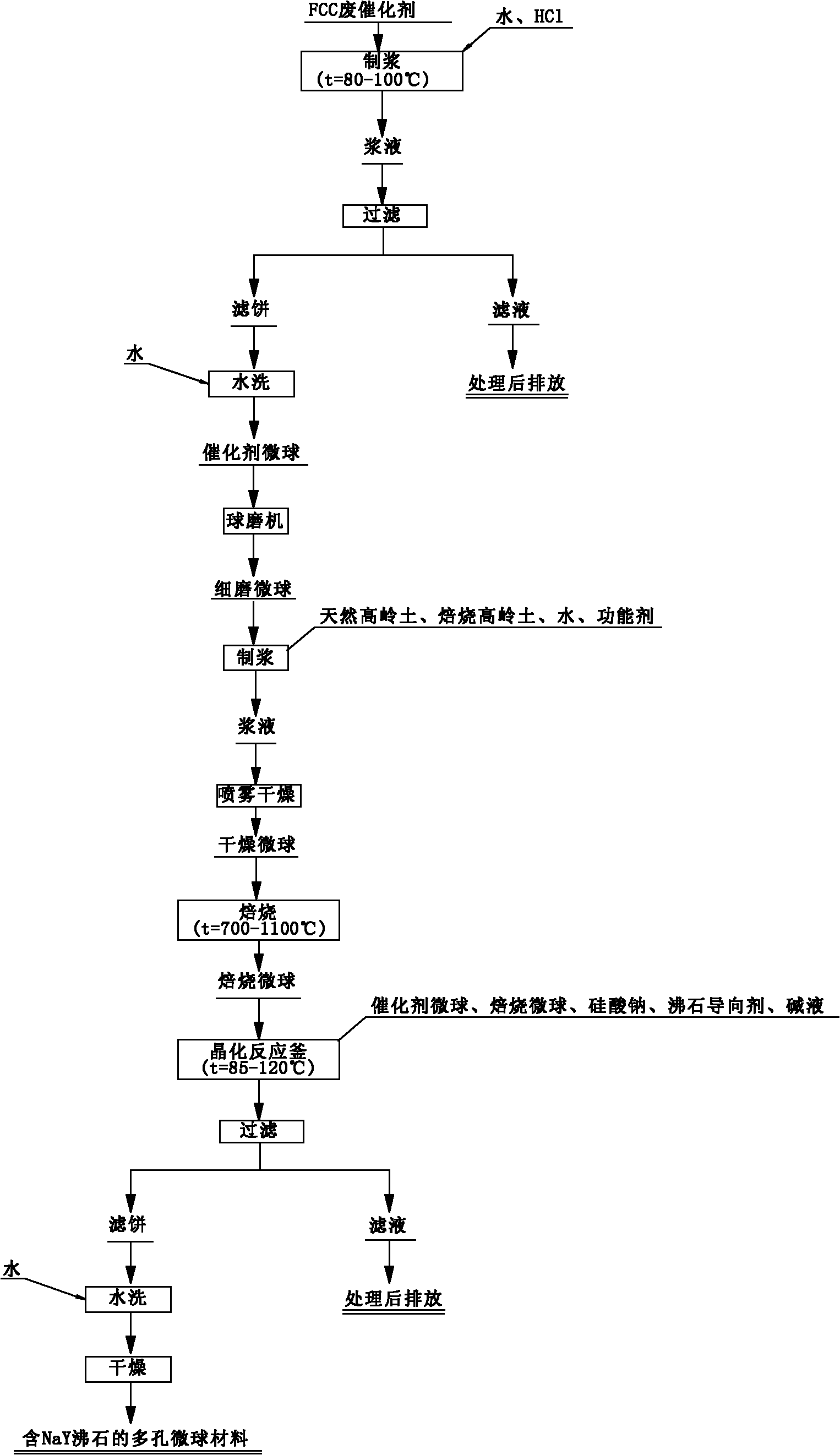

Method used

Image

Examples

Embodiment 1

[0029](1) Add water to 2000g of FCC waste catalyst to make a slurry with a solid content of 30%, adjust the final pH value of the slurry to 2.5 with 8% hydrochloric acid, heat to 94°C, react for 1.0 hour, filter, wash with water, and obtain catalyst microspheres; The test shows that the specific surface of the catalyst increases by 86.13m 2 / g, the pore volume increased by 0.053ml / g, the nickel decreased by 1417ppm, and the vanadium decreased by 418ppm.

[0030] (2) Get 1300g of catalyst microspheres and grind them with a ball mill until the median diameter is 1.9 μm;

[0031] (3) Get 1000g natural kaolin and 900g catalyst microspheres and add water to make a slurry with a solid content of 32%, add 250ml sodium silicate, spray dry and form dry microspheres, the median diameter of the microspheres is 70.35 μm, and the microspheres Placed in the muffle furnace, roasted at 706°C for 6 hours to obtain roasted microspheres;

Embodiment 2

[0034] (1) Add water to 2000g FCC waste catalyst to make a slurry with a solid content of 50%, adjust the final pH value of the slurry to 3.5 with 6% hydrochloric acid, heat to 96°C, react for 2.5 hours, filter, wash with water, and obtain catalyst microspheres; The test shows that the specific surface of the catalyst increases by 73.15m 2 / g, the pore volume increased by 0.051g / l, the nickel decreased by 1209ppm, and the vanadium decreased by 291ppm;

[0035] (2) Get 600g of catalyst microspheres and grind them with a ball mill until the median diameter is 1.3 μm;

[0036] (3) Get 4500g of natural kaolin and 500g of catalyst microspheres and add water to make a slurry with a solid content of 34%, add 315ml of sodium silicate, 87g of Tianqing powder, spray dry and form dry microspheres, and the median diameter of the microspheres is 68.78 μm , placing the microspheres in a muffle furnace and roasting at 983°C for 1.5 hours to obtain roasted microspheres;

[0037] (4) Put 292...

Embodiment 3

[0039] (1) Add water to 1000g of FC waste C catalyst to make a slurry with a solid content of 40%, adjust the final pH value of the slurry to 4.5 with 5% hydrochloric acid, heat to 98°C, react for 10 hours, filter, and wash with water to obtain catalyst microspheres; After testing, the specific surface of the catalyst was increased by 49.28m 2 / g, the pore volume increased by 0.023g / l, the nickel decreased by 1356ppm, and the vanadium decreased by 311ppm;

[0040] (2) Get 500g of natural kaolin and 1500g of roasted kaolin and add water to make a slurry with a solid content of 37%, add 300ml of sodium silicate, 50ml of sodium phosphate, and 85g of polyacrylamide, and spray dry to form dry microspheres. The diameter is 71.43 μm, the microspheres are placed in the muffle furnace, and roasted at 868 ° C for 3 hours to obtain the roasted microspheres;

[0041] (3) Put 2916ml of sodium silicate, 793ml of lye, 652ml of zeolite directing agent, 650g of catalyst microspheres, and 850g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com