Method for synthesizing particle reinforced composite material under pulsed electric field and electromagnetic field

A pulsed electric field and composite material technology is applied in the field of preparation of particle-reinforced metal matrix composite materials, which can solve the problems of difficulty in improving the reaction speed and efficiency, and the easy agglomeration and growth of particle-reinforced phases, so as to promote the control of particle morphology and synthesis. The effect of shortening the time and increasing the amount of spawns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

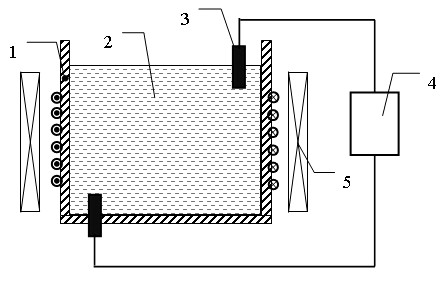

Method used

Image

Examples

Embodiment 1

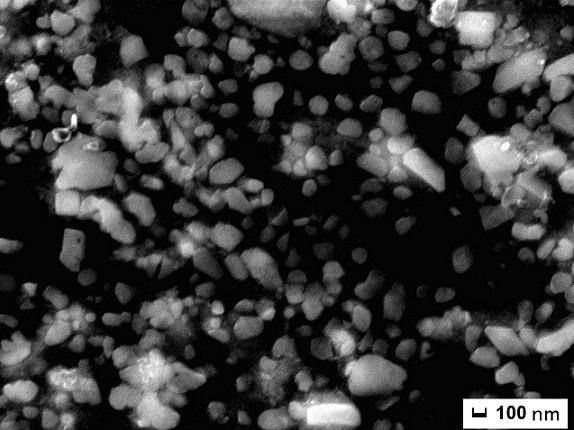

[0031] Embodiment 1: Preparation of ZrB 2 Particulate Reinforced Aluminum Matrix Composites

[0032] Raw materials: base metal: aluminum alloy; solid powder: potassium fluozirconate and potassium fluoborate powder (purity: 99%), refining degassing agent and slag removal agent;

[0033] The preparation process is as follows:

[0034] (1) First metal smelting and powder preparation:

[0035] Aluminum alloy 50Kg is melted in a 25kW crucible resistance furnace and heated up to 900°C, degassed and slag removed; all reagents used are fully dried at 200°C, and the reaction salt is ground into fine powder (with a particle size of less than 100 mu m), weighed and ready to use, the weight of the reaction salt added is 20% of the weight of the metal (the weight ratio of potassium fluozirconate to potassium fluoborate is: 6.2:7.8).

[0036] (2): Melt reaction synthesis to prepare composite material melt:

[0037] After the melt temperature is qualified, a refining is carried out, an...

Embodiment 2

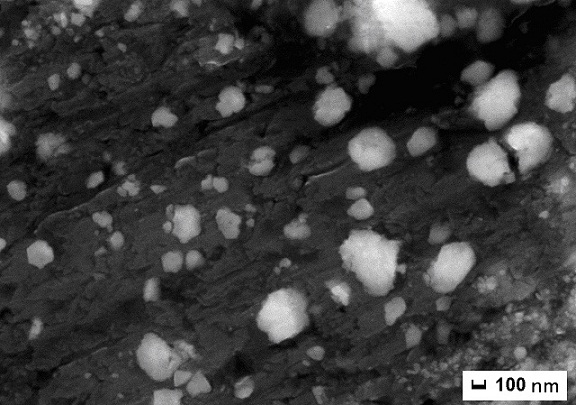

[0043] Implementation example 2: preparation (Al 3 Zr (s) +Al 2 o 3(s) ) particle reinforced aluminum matrix composites

[0044] Raw materials: base metal: aluminum alloy; solid powder: industrial zirconium carbonate (Zr(CO 3 ) 2 ) powder (purity 99.20%), refining degassing agent and slag removal agent;

[0045] In situ reaction equation: 7Al (l) +Zr(CO 3 ) 2(s) =Al 3 Zr (s) +2Al 2 o 3(s) ;

[0046] Particle reinforcement phase: Al 3 Zr (s) and Al 2 o 3(s) ;

[0047] The preparation process is as follows:

[0048] (1) First metal smelting and powder preparation:

[0049] Aluminum alloy 50Kg was melted in a 25kW crucible resistance furnace and heated up to 900°C, degassed and slag removed; all reagents used were fully dried at 300°C, of which Zr(CO 3 ) 2 Grind into fine powder (particle size less than 100 mu m), ready to use after weighing, Zr(CO 3 ) 2 The added weight is 10% of the metal weight (Note: The theoretical volume fraction of ...

Embodiment 3

[0054] Implementation example 3 preparation (Al 3 Zr (s) + ZrB 2(s) ) Particle-reinforced Al-based composites

[0055] Raw materials: base metal: 7055 aluminum alloy; reaction salt: K 2 ZrF 6 -KBF 4 (Mass ratio 6.2:7.8) Mixed salt powder, refining degassing agent and slag removal agent;

[0056] The preparation process is as follows:

[0057] (1) First metal smelting and powder preparation:

[0058] 100Kg 7055 aluminum alloy is melted in a crucible-type induction furnace and heated to 900°C, degassed, slag removed, and ready for use; all reagents used are fully dried at 250°C-300°C, of which K 2 ZrF 6 -KBF 4 , to be ground into fine powder (particle size less than 200 mesh), the added weight is 20% of the metal weight.

[0059] (2): Melt reaction synthesis to prepare composite material melt:

[0060] Its operation process and the method adopted are identical with embodiment 1, and the electromagnetic parameter scope of the pulse electric field used is: pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com