Cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and reclaimed rubber

A technology of EPDM and peroxide, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of low compression deformation, difficult to meet high cold resistance, etc., achieve low compression deformation, reduce The effect of dynamic heat generation, good high temperature resistance and electrical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

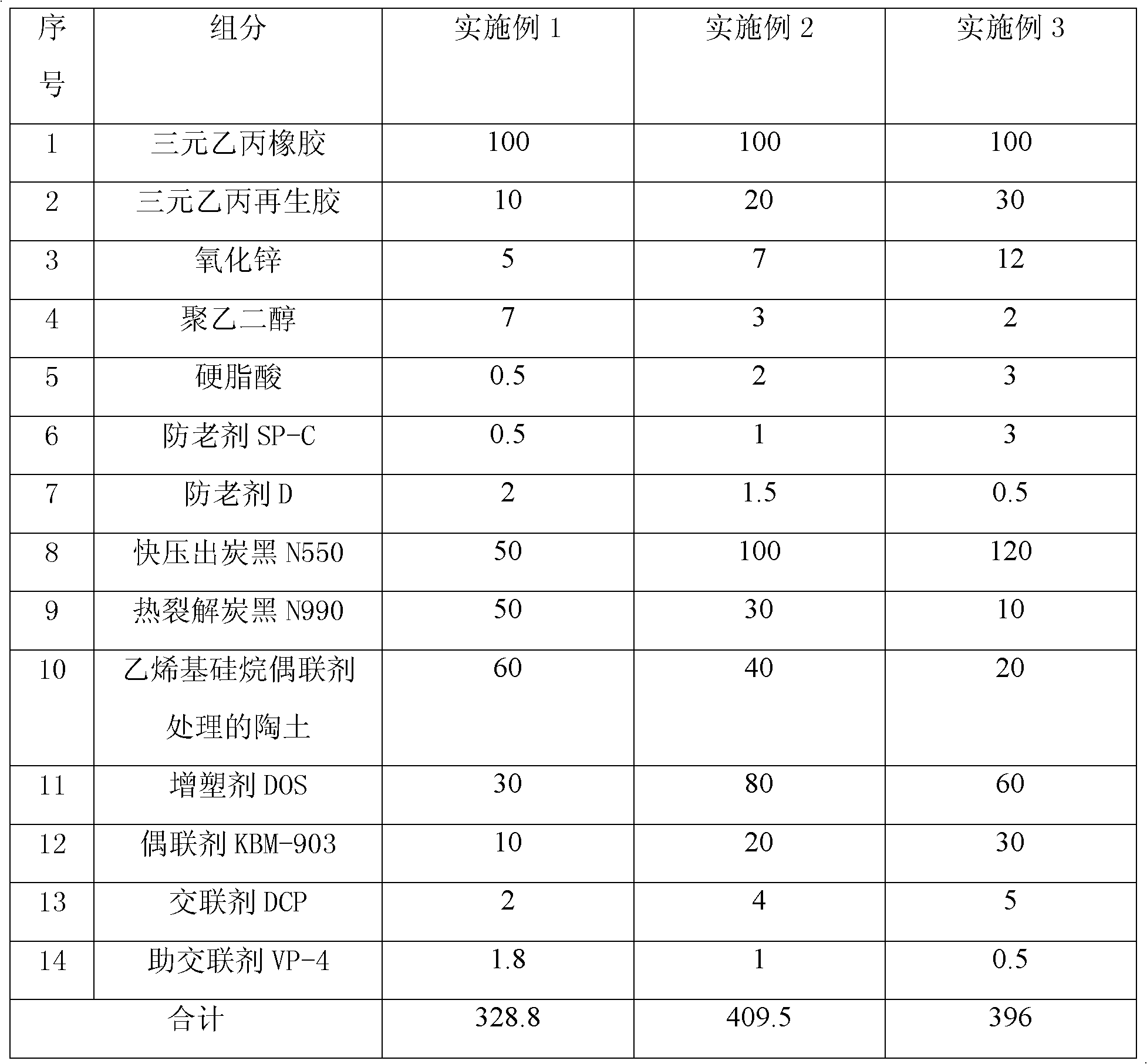

[0019] The embodiment of the cold-resistant rubber hose used in combination with peroxide EPDM rubber and reclaimed rubber:

[0020] In parts by mass

[0021]

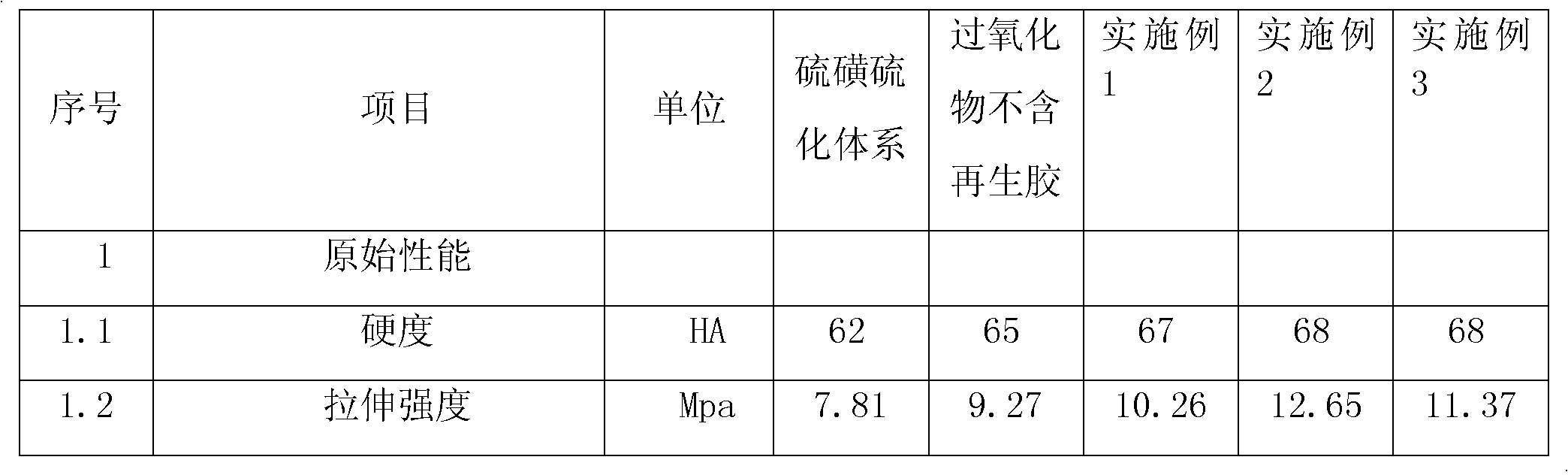

[0022] According to the raw materials in the formula in the implementation list, the film was made into a film for testing and testing. The performance comparison of the cold-resistant rubber hose formula using peroxide EPDM rubber and reclaimed rubber with the sulfur vulcanization system and peroxide system without reclaimed rubber hose is as follows:

[0023]

[0024]

[0025] From the data in the above table, it can be concluded that the cold-resistant rubber hose formula using peroxide EPDM rubber and reclaimed rubber is not only cold-resistant, but also resistant to cooling fluid and Electrical properties, ozone resistance and heat aging resistance are better, and the compression set is lower, the elongation, tear strength and tear strength are also better, which can better meet the cooling system circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com