Insulation pressure-resistant liner mouth sealing ring and preparation method thereof

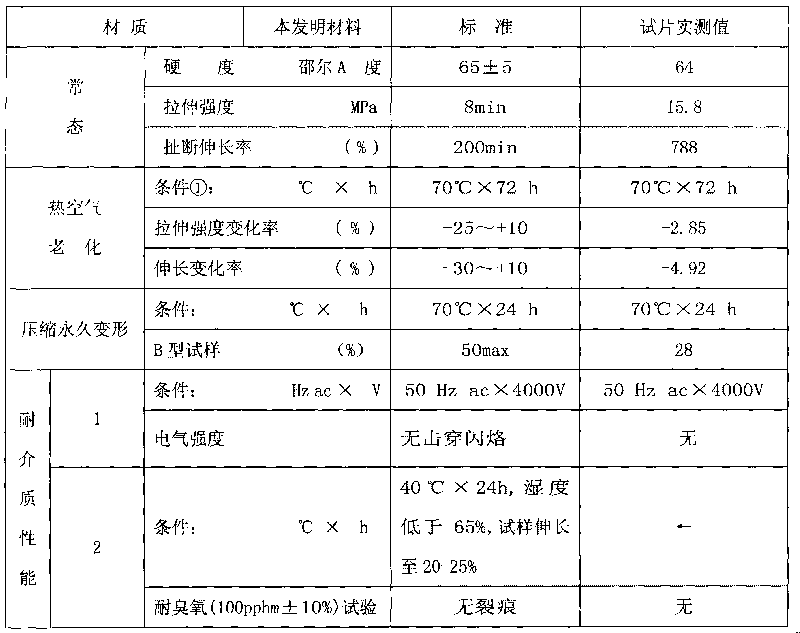

A technology of insulation and pressure resistance and sealing ring, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve the problems of hardness, tensile strength, elongation at break, low heat aging resistance, low heat aging resistance and Compression resistance, intolerance to 50HZ and other issues, to achieve excellent aging resistance and anti-ozone performance, high resistance to compression set, reasonable ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An insulating and pressure-resistant gall opening sealing ring, comprising the following raw materials in parts by weight:

[0035] 80 parts of EPDM rubber, 1 part of antioxidant RD, 40 parts of carbon black,

[0036] 3 parts of 2,4-dichlorobenzoyl peroxide, 0.5 part of accelerator TMTD,

[0037] 6 parts of dioctyl phthalate, 1 part of dispersant WB212.

[0038] The present invention is a preparation method of an insulating and pressure-resistant bile mouth sealing ring, comprising the following steps:

[0039] Mix 80 parts of EPDM rubber, 1 part of antioxidant RD, 40 parts of carbon black, 3 parts of 2,4-dichlorobenzoyl peroxide, 0.5 parts of accelerator TMTD, 6 parts of phthalic acid with an internal mixer Dioctyl ester and 1 part of dispersant WB212 synthetic rubber, the synthetic rubber is shaped with an open mill, and then the shaped rubber is put into a mold in a vulcanizer for vulcanization, and the parameter condition is that the pressure is 1kgf / cm 2 , the t...

Embodiment 2

[0041] An insulating and pressure-resistant gall opening sealing ring, comprising the following raw materials in parts by weight:

[0042] 100 parts of EPDM rubber, 4 parts of antioxidant MB, 80 parts of carbon black,

[0043] 5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane,

[0044] 2 parts of 2,2-dibenzothiazole disulfide,

[0045] 10 parts of bis(2-ethyl)hexyl sebacate,

[0046] 4 parts of dispersant W33.

[0047] The present invention is a preparation method of an insulating and pressure-resistant bile mouth sealing ring, comprising the following steps:

[0048] Mix 100 parts of EPDM rubber, 4 parts of antioxidant MB, 80 parts of carbon black, 5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 2 parts of 2,2-dibenzothiazole disulfide, 10 parts of di(2-ethyl) hexyl sebacate and 4 parts of dispersant W33 synthetic rubber, and then the synthetic rubber was shaped with an open mill, and then The molded rubber is put into the mold in the vulcanizer for vulcaniz...

Embodiment 3

[0050] An insulating and pressure-resistant gall opening sealing ring, comprising the following raw materials in parts by weight:

[0051] 100 parts of EPDM, 2 parts of anti-aging agent IPPD, 60 parts of carbon black,

[0052] 4 parts of dicumyl peroxide, 1 part of zinc di-n-butyl dithiocarbamate,

[0053] 7 parts of dioctyl adipate, 2 parts of dispersant Aflux.

[0054] The present invention is a preparation method of an insulating and pressure-resistant bile mouth sealing ring, comprising the following steps:

[0055] Mix 100 parts of EPDM, 2 parts of anti-aging agent IPPD, 60 parts of carbon black, 4 parts of dicumyl peroxide, 1 part of zinc di-n-butyl dithiocarbamate, 7 parts of hexanediol using an internal mixer. Dioctyl acid and 2 parts of dispersant Aflux synthetic rubber, then the synthetic rubber is shaped with an open mill, and then the shaped rubber is put into the mold in the vulcanizer for vulcanization. The parameter conditions are: the pressure is 5kgf / cm 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com