Variable pressure absorption oxygen and nitrogen combined separation method and device

A pressure swing adsorption, adsorption separation technology, applied in separation methods, nitrogen purification/separation, dispersed particle separation, etc., can solve the problems of complex types, limited separation selectivity, and difficult industrial use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The above-mentioned content of the present invention will be further described in detail below through specific implementation methods in the form of examples. However, it should not be understood that the scope of the subject matter of the present invention is limited to the following examples, and all technologies realized based on the above content of the present invention belong to the scope of the present invention.

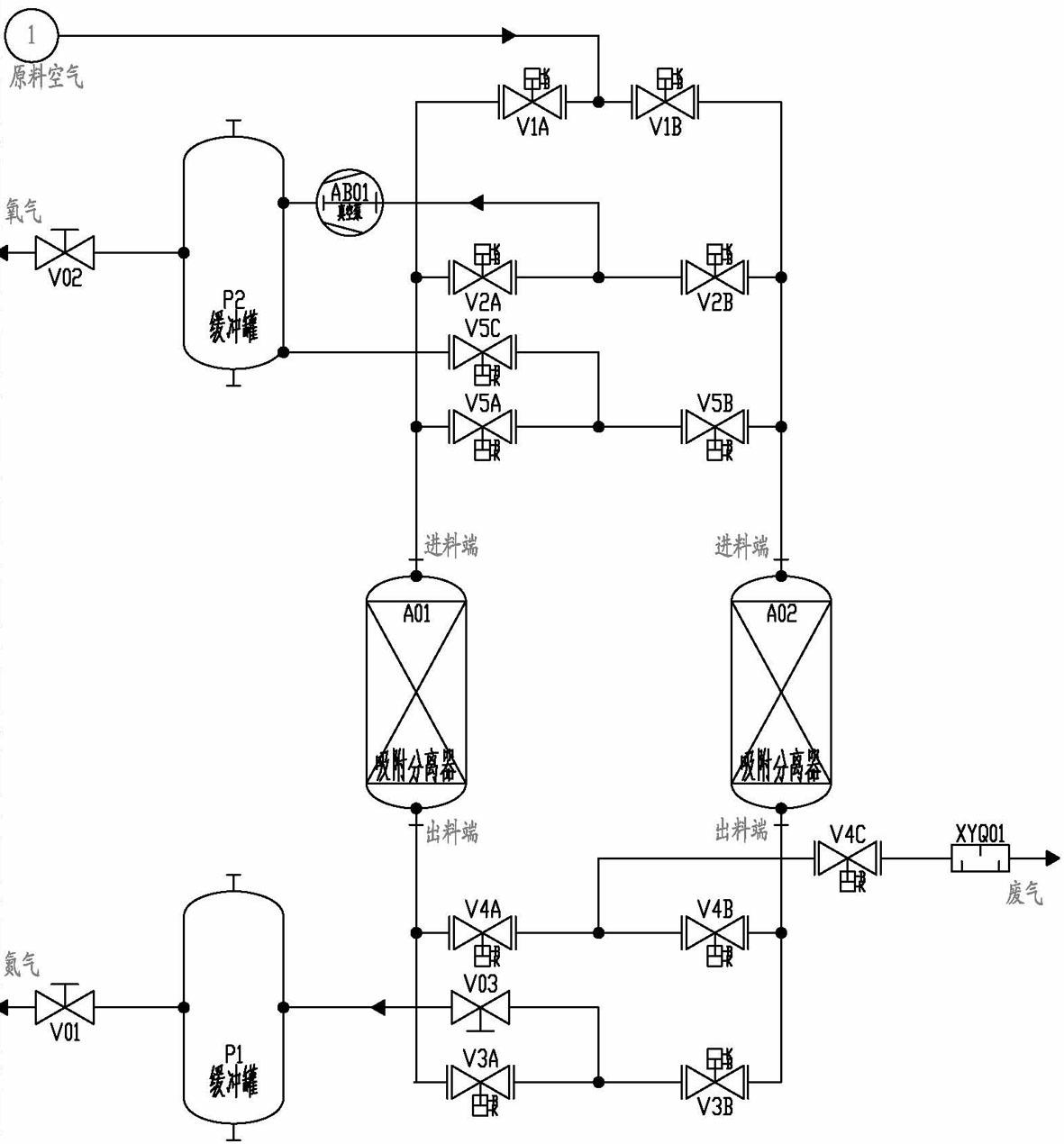

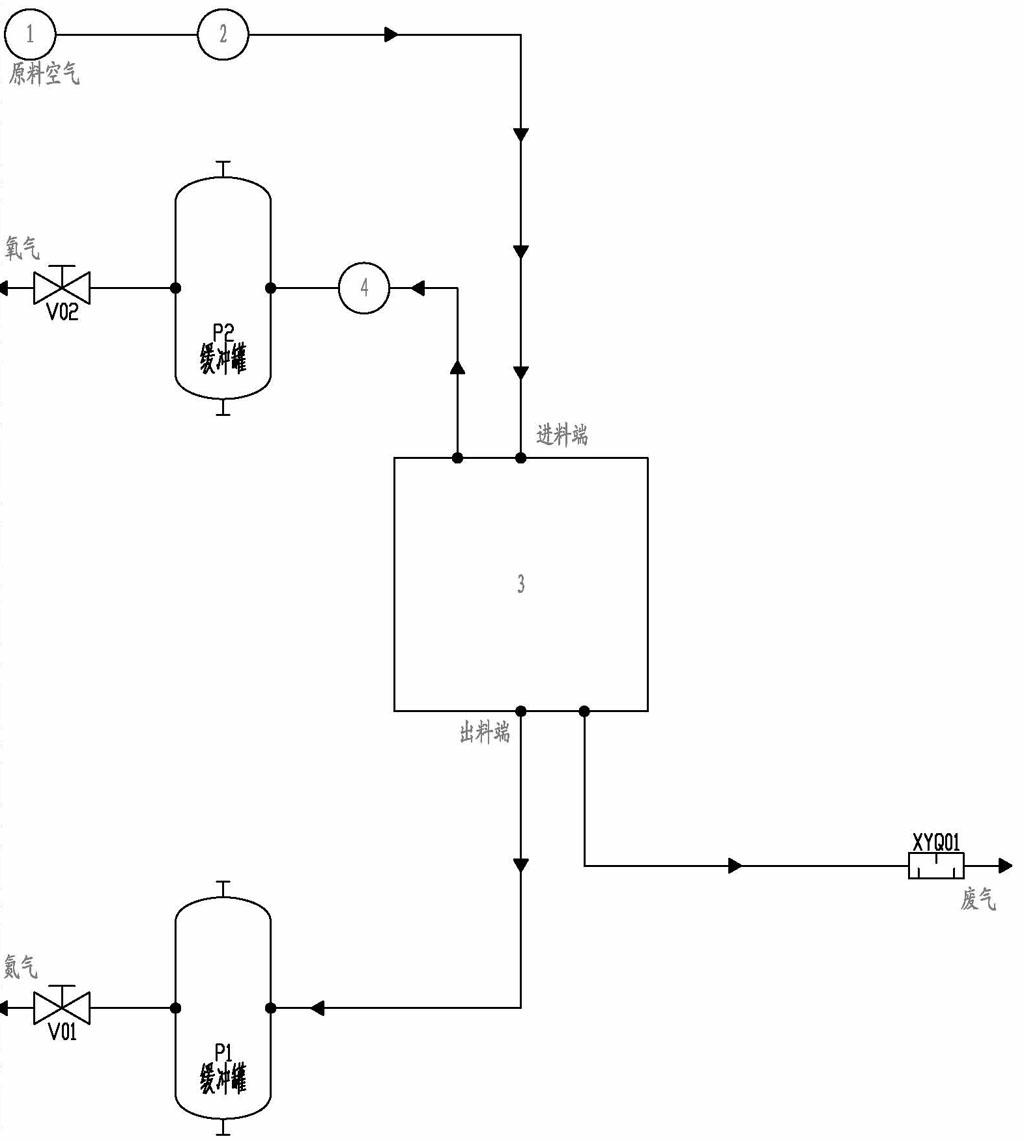

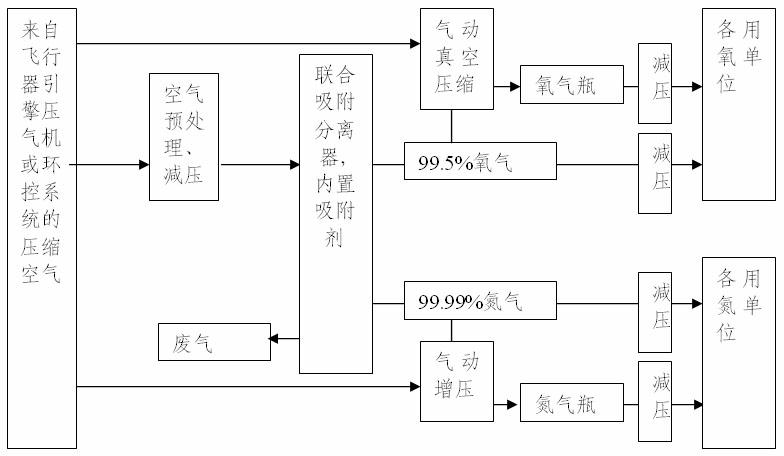

[0064] figure 1 Among them, 1 is the compressed air drawn from the aircraft engine compressor, environmental control system or other air inlet, that is, the raw air, which can be selectively passed through the pressure reducing valve or throttled to 3-5 bar, and an air pretreatment can be selected The device is to remove particles, impurities, etc. from the raw material air to meet the needs of the subsequent separation unit. Generally, the removal device will intercept most of the particulate impurities, even moisture, carbon dioxide, etc.; V1A and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com