High-efficiency compound demulsifier for heavy and poor crude oil

A technology of inferior crude oil and demulsifier, which is applied in the direction of dehydration/demulsification by electric/magnetic method, dehydration/demulsification by chemical method, etc., which can solve the problems of large amount of use, long dehydration time, and insignificant effect of demulsification and dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

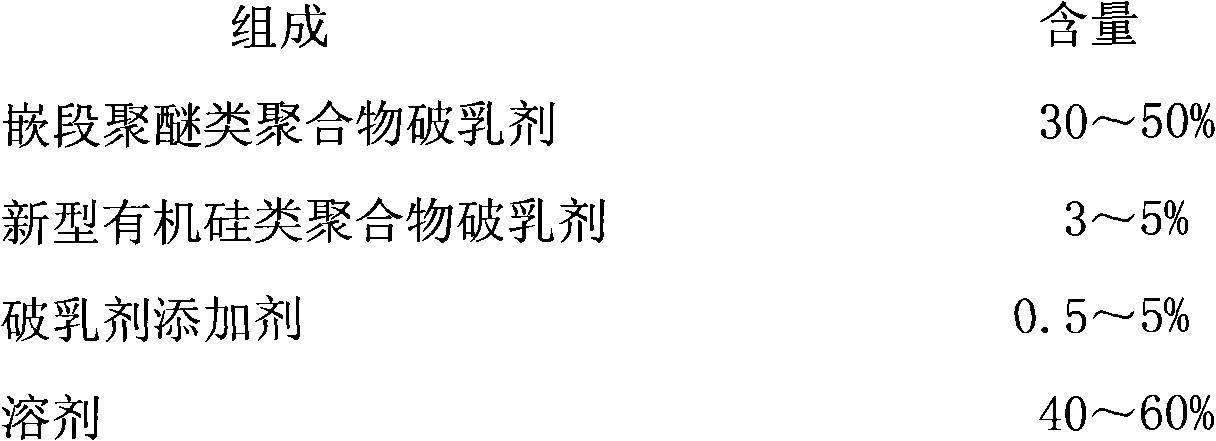

Method used

Image

Examples

Embodiment A

[0017] Demulsifier thermochemical sedimentation evaluation test:

[0018] Test procedure: 90g of Liaohe heavy oil + 10g of distilled water, preheated in a constant temperature water bath at 80°C for 5 minutes, mixed manually 60 times, and settled in a constant temperature water bath for comparison. The data of sedimentation demulsification and dehydration efficiency are as follows:

[0019]

[0020] Embodiment A composite demulsifier composition:

[0021] Demulsifier AP221, 15% Demulsifier AR36, 25%

[0022] New silicone polymer demulsifier (grade: 1636), 5%

[0023] Dodecylbenzenesulfonic acid, 0.5%

[0024] Mixed xylene solvent, 30% hydrocarbon solvent oil 200#, 24.5%

Embodiment B

[0026] Demulsifier thermochemical sedimentation evaluation test:

[0027] Test procedure: Mix heavy oil (sand weight: Iraqi weight = 1:9) 80 + distilled water 20g, preheat in a constant temperature water bath at 85°C for 5 minutes, mix manually 60 times, and stand still in a constant temperature water bath for sedimentation comparison. The data of sedimentation demulsification and dehydration efficiency are as follows:

[0028]

[0029]

[0030] Embodiment B demulsifier composition:

[0031] Demulsifier BP2070, 10% Demulsifier AR46, 35%

[0032] New silicone polymer demulsifier (grade: 606), 5%

[0033] Dodecylbenzenesulfonic acid, 0.5% Isopropanol, 4.5%

[0034] Aromatic solvent, 45%

Embodiment C

[0036] Test procedure: Sudan crude oil (higher acid value) 80g + distilled water 20g, preheat in a constant temperature water bath at 60°C for 5 minutes, mix manually 60 times, and stand still in a constant temperature water bath for sedimentation comparison. The data of sedimentation demulsification and dehydration efficiency are as follows:

[0037]

[0038] Embodiment C demulsifier composition

[0039] New silicone polymer demulsifier (brand: 1636), 5%;

[0040] Demulsifier AP221, 10% Demulsifier BP2070, 10% Demulsifier AR2, 25%;

[0041] Dodecylbenzenesulfonic acid, 0.5% isopropanol, 1% n-butanol, 0.5%.

[0042] Mixed aromatic solvent, 51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com