Preparation and application of chemical derusting cleaning agent

A rust-removing cleaning agent and chemical technology, applied in the direction of metal material coating process, etc., can solve the problems of scrapping, non-regenerating, and poor dissolving ability of the filter, and achieve less discharge of waste liquid, no harm to health, and no pollution to the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

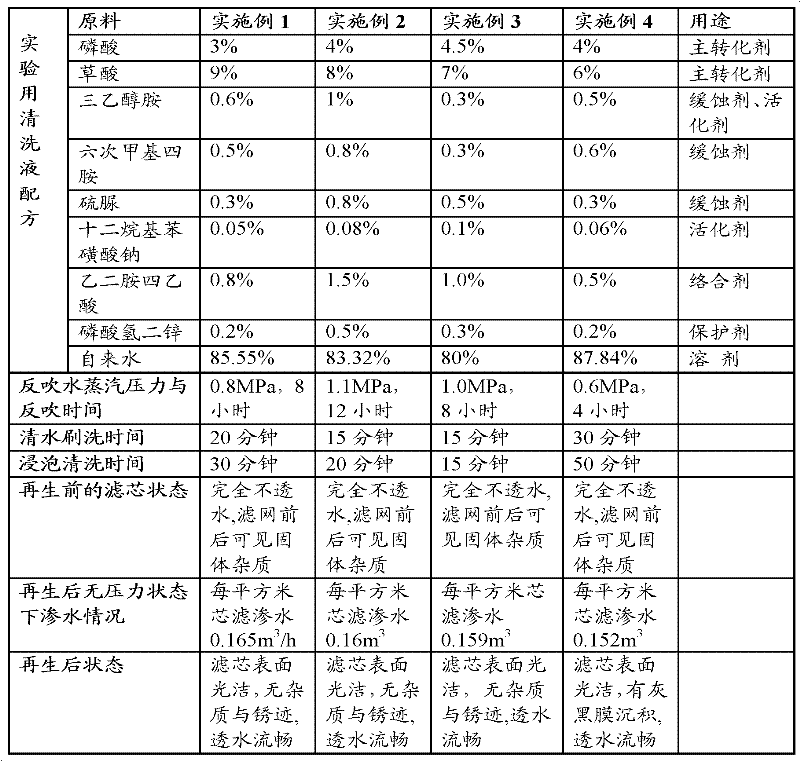

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that these preferred embodiments are only exemplary and not intended to limit the spirit and scope of the present invention in any way.

[0027] The substances that block the filter channel of the filter are mainly: wax, fine catalyst particles, active iron particles, and iron carbide particles. The iron in the catalyst exists in the form of reduced active elemental iron, oxidized iron, and iron carbide. The active iron and iron carbide can be quickly and automatically oxidized in the air and converted into iron oxides.

[0028] The present invention utilizes active iron catalyst and iron carbide to be automatically oxidized into various oxides of iron (such as Fe 2 o 3 , FeO) presents the characteristics of rust, and the filter is regenerated by using a chemical derusting cleaning solution containing a variety of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com