Lifting rod assembly structure for pipe type wet electric dust remover

A wet electrostatic precipitator and boom technology, which is applied to external electrostatic separators, electrostatic separation, electrode conveying devices, etc., can solve the problems of spark discharge, ineffective contact between the conductive boom and the cathode beam, etc. Cleverly designed, technologically advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

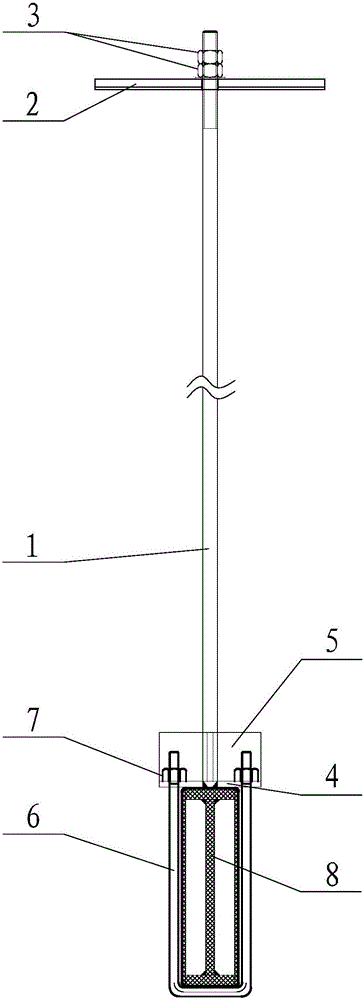

[0017] Such as figure 1 As shown, the suspender integrated structure used for the tubular wet electrostatic precipitator includes a gland 2, a suspender, a cathode girder 8 and two U-shaped bolts 6; the suspender includes a screw 1, and the top of the screw 1 is set A threaded section, a gland 2 is sleeved on the threaded section, and a nut assembly 3 is threaded on the threaded section, the nut assembly 3 is located outside the gland 2, the bottom end of the screw rod 1 is provided with a hanging plate 4, and the hanging plate 4 is evenly arranged Several installation holes; the U-shaped bolt 6 includes a round rod body, the round rod body is bent to form a U-shaped rod, and screw segments are arranged at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com