Preparation method and film forming method of segmented copolymers with fullerene at main chain

A technology of block copolymers and fullerenes, which is used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. It can solve problems such as segment distortion and deformation, and achieve the effect of high input-output ratio, saving consumption and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare the block copolymer that main chain contains fullerene, concrete steps are as follows:

[0033] (1) Add 150ml of anhydrous tetrahydrofuran, 16mmol of 2,5-dibromo-3-hexylthiophene and 16mL of 1M tetrahydrofuran solution to a 250ml three-necked flask, and reflux at 75°C for 3h. Add 0.36mmol diphenylphosphinopropane nickel chloride (Ni(dppp)Cl 2 ), stirring for 6h. Slowly add 150 mg lithium aluminum hydride (LiAlH 4 ) to terminate the reaction, excess LiAlH 4 Remove by dropwise addition of 1M hydrochloric acid (HCl). The reaction solution was poured into methanol for precipitation, centrifuged at 4000rpm, and subjected to Soxhlet extraction with methanol (to remove monomers and salts), hexane (to remove catalysts and oligomers) and chloroform, and finally the chloroform solution of the product was concentrated Pour into methanol to precipitate again, centrifuge at 4000rpm, and dry under reduced pressure at 50°C to obtain poly(3-hexylthiophene) (P3HT) with a yie...

Embodiment 2

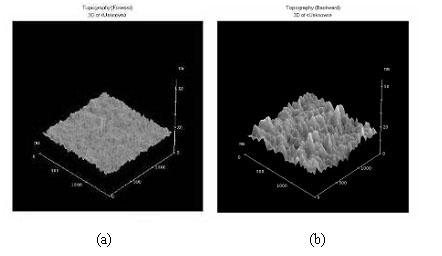

[0045] Same as Example 1, but the amount of lactide was changed to 100 mg. The photosensitive properties of the triblock copolymer films are shown in Figure 4 .

Embodiment 3

[0047] Same as Example 1, but the amount of lactide was changed to 150 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com