Corrosion-resistant sealing glass material for primary lithium battery and preparation method thereof

A technology for sealing glass and lithium batteries, which is applied in the field of corrosion-resistant sealing glass materials for primary lithium batteries and its preparation, and can solve problems such as poor glass wetting performance and air tightness, poor water resistance of glass, battery leakage failure, etc. problems, to achieve the effect of improving fluidity and chemical stability, good sealing, and improving wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

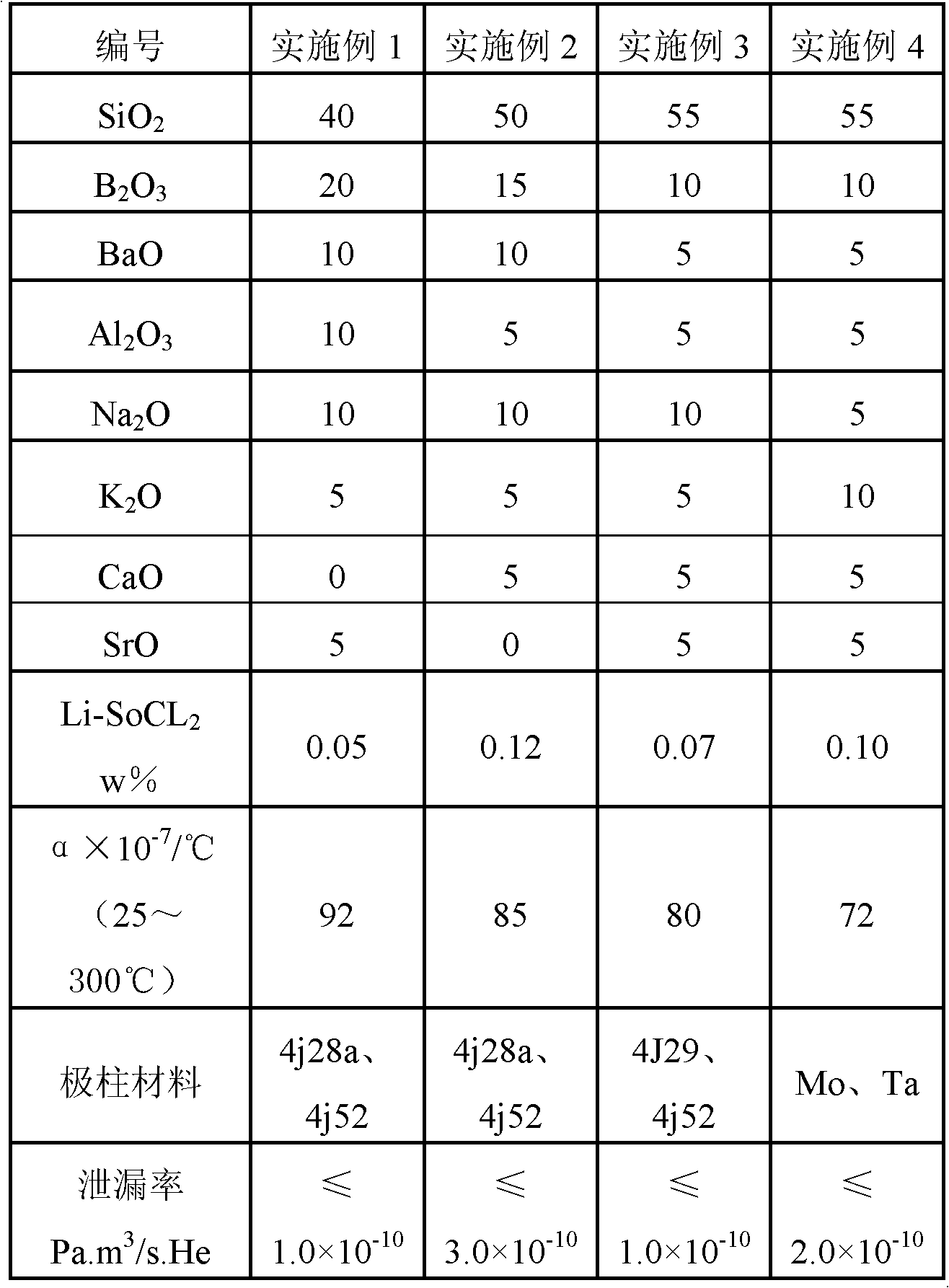

[0023] The corrosion-resistant sealing glass material for primary lithium batteries proposed by the present invention, in mole percent, contains the following components: SiO 2 : 40~60%; B 2 o 3 : 10~30%; BaO: 5~10%; K 2 O: 5-10%; Na 2 O: 5-10%; Al 2 o 3 : 5-10%; CaO: 0-5%; SrO: 0-5%. The preparation method of this kind of corrosion-resistant sealing glass material comprises the following four steps:

[0024] 1) According to the molar ratio of each component, the ingredients are prepared by introducing oxide raw materials;

[0025] Among them, quartz sand is introduced into silica, analytically pure boric acid is introduced into diboron trioxide, analytically pure barium carbonate is introduced into barium oxide, analytically pure sodium carbonate is introduced into sodium oxide, analytically pure potassium carbonate is introduced into potassium oxide, aluminum hydroxide is introduced into aluminum oxide , Calcium carbonate is introduced into calcium oxide, and analytic...

Embodiment 1

[0034] Dosing is carried out according to the molar percentage composition in Table 1, and the batching is carried out by introducing oxide raw materials, specifically: introducing silicon dioxide with quartz sand, introducing diboron trioxide with analytically pure boric acid, introducing barium oxide with analytically pure barium carbonate, and introducing boron trioxide with analytically pure boric acid. Sodium carbonate is introduced into sodium oxide, analytically pure potassium carbonate is introduced into potassium oxide, aluminum hydroxide is introduced into aluminum oxide, calcium carbonate is introduced into calcium oxide, and analytically pure strontium oxide is introduced into strontium oxide. Mix the oxide raw materials of each component evenly to make a batch.

[0035] Put the pretreated glass mixture in a platinum crucible and melt it in a silicon-molybdenum furnace: heat up at a rate of 50°C / min, heat to 1450°C and keep it for 40min, and clarify at 1460°C.

[0...

Embodiment 2

[0040] Dosing according to the composition in Table 1, compared with Example 1, reducing the content of strontium oxide, and comparing the resistance of glass to electro-hydraulic corrosion.

[0041] The pretreated glass mixture was placed in a platinum crucible, heated to 1440°C for 40 minutes in a silicon-molybdenum furnace, and clarified at 1450°C.

[0042] Pour the melted glass liquid into the mold to prepare samples according to the test requirements, and pour the rest into cold water.

[0043] The samples in the mold were taken out and processed according to the test requirements and tested. The test results are shown in Table 1.

[0044] The average thermal expansion coefficient of this example at 25-300°C is 85×10 -7 / °C, good match with 4j28a, 4j52 center pole; leak rate ≤3.0×10 -10 Pa.m3 / s; weight erosion ratio 0.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com