Composite polymer electrolyte film for lithium ion battery and preparation method thereof

A lithium-ion battery and electrolyte membrane technology, applied in the field of composite polymer electrolyte membrane and its preparation, can solve the problems of low cost, high room temperature ion conductivity, large interface impedance, etc., achieve good elasticity and processability, and improve safety performance , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

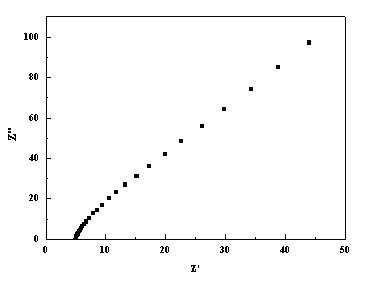

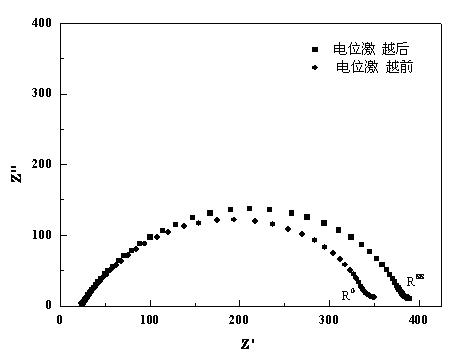

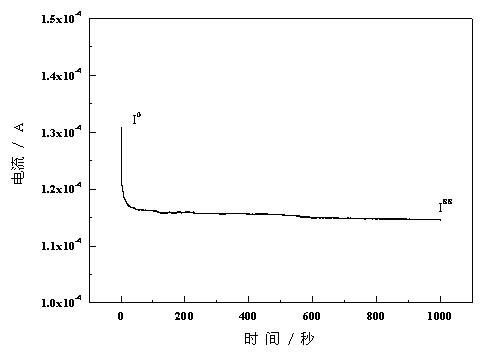

Image

Examples

Embodiment 1

[0017] Embodiment 1: Get 5 grams of NASICON type lithium conductive ceramics Li 1.5 al 0.5 Ge 1.5 P 3 o 12 Join in the dimethylformamide solution of the polyvinylidene fluoride-hexafluoropropylene copolymer that 45 grams of mass fractions are 10%, at 30 o After stirring at C for 12 hours, cast a film on a clean glass plate, evaporate the solvent, and obtain a composite polymer film.

Embodiment 2

[0018] Embodiment 2: Get 10 grams of LISICON type lithium conductive ceramics Li 14 Zn(GeO 4 ) 4 Add 50 grams of an aqueous solution of polyethylene oxide with a mass fraction of 5%, ultrasonically disperse at room temperature for 6 hours, and cast it on a clean glass plate to form a film, and evaporate the solvent to obtain a composite polymer film.

Embodiment 3

[0019] Embodiment 3: Take 1 gram of perovskite lithium conductive ceramic La 0.55 Li 0.33 TiO 3 Join in the acetonitrile solution that is 20% acrylonitrile in 45 gram mass fractions, at 20 o After stirring and dispersing at C for 10 hours, cast the film on a clean polytetrafluoroethylene plate, and volatilize the solvent to obtain a composite polymer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com