Titanium acid lithium battery cathode material containing rare metal elements

A rare metal element, lithium titanate battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electrochemical capacity, achieve the effects of low equipment requirements, good reproducibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Lithium hydroxide, anatase titanium dioxide and cerium oxide are selected as raw materials, wherein the molar ratio of lithium hydroxide to anatase titanium dioxide is 0.81:1, and cerium oxide accounts for 1 wt% of the total weight of the three raw materials. The three raw materials were mixed, methanol dispersant was added, ball milled on a ball mill for 6 hours, and the precursor was obtained after microwave drying.

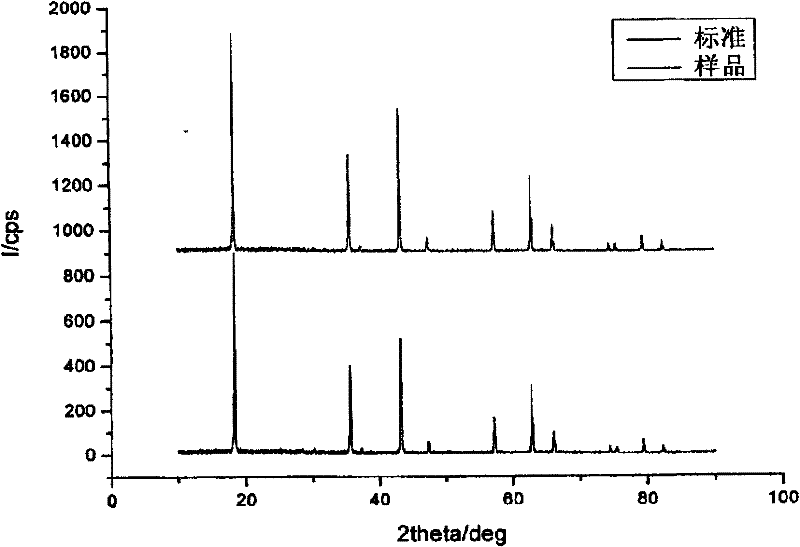

[0028] The precursor is further processed as follows: firstly in the air atmosphere at a temperature of 500 ° C, high temperature treatment for 2 hours, after cooling, the ball mill passes through a 150 mesh sieve, and the product after sieving is kept at a temperature of 500 ° C for 2 hours, and then the temperature is raised to 800 ° C Keep warm for 8 hours, then cool down to 600°C and keep warm for 2 hours, and finally cool down to room temperature and then ball mill through a 150-mesh sieve to get lithium titanate Li 4 Ti 5 o 12 sample. Observed b...

Embodiment 2

[0031] Lithium carbonate, anatase titanium dioxide and neodymium oxide are selected as raw materials, wherein the molar ratio of lithium carbonate and anatase titanium dioxide is 0.85:1, and neodymium oxide accounts for 3 wt% of the total weight of the three raw materials. Mix the three raw materials, add ethanol dispersant, ball mill on a ball mill for 7 hours, and microwave dry to obtain the precursor.

[0032] The precursor is further processed as follows and the further processing is the same as in Example 1. Observed by an electron microscope (SEM), the material particles are uniform and fine. After the X-ray powder diffraction (XRD) test, the pH value of the single spinel structure is 10.5, and the particle size analysis particle D50 is 4um.

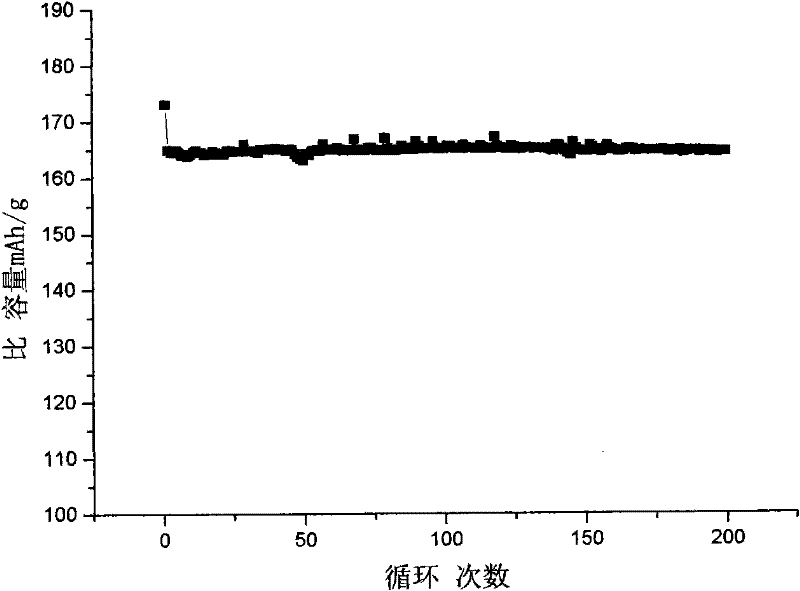

[0033] The preparation of the pole piece, the assembly of the button cell and the electrochemical performance test are the same as in the first embodiment. For the first time, the specific capacity is 160mAh / g, and the performance...

Embodiment 3

[0035] Lithium hydroxide, gold-red titanium dioxide and cerium oxide are selected as raw materials, wherein the molar ratio of lithium hydroxide to anatase titanium dioxide is 0.8:1, and cerium oxide accounts for 0.5 wt% of the total weight of the three raw materials. Mix the three raw materials, add ethanol dispersant, ball mill on a ball mill for 6 hours, and microwave dry to obtain the precursor.

[0036] The precursor is further processed as follows and the further processing is the same as in Example 1. Observed by an electron microscope (SEM), the material particles are uniform and fine. After the X-ray powder diffraction (XRD) test, the pH value of the single spinel structure is 10.9, and the particle size analysis particle D50 is 5um.

[0037] The preparation of the pole piece, the assembly of the button cell and the electrochemical performance test are the same as in the first embodiment. For the first time, the specific capacity is 150mAh / g, and the performance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com