Lithium-ion battery anode material, anode and lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of limited coating amount, poor fast charge and discharge performance, uneven coating, etc., and achieve good charge and discharge performance , Improve electrical conductivity and improve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

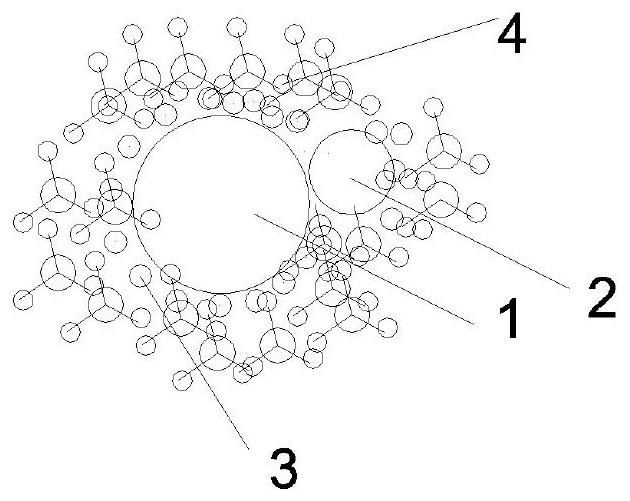

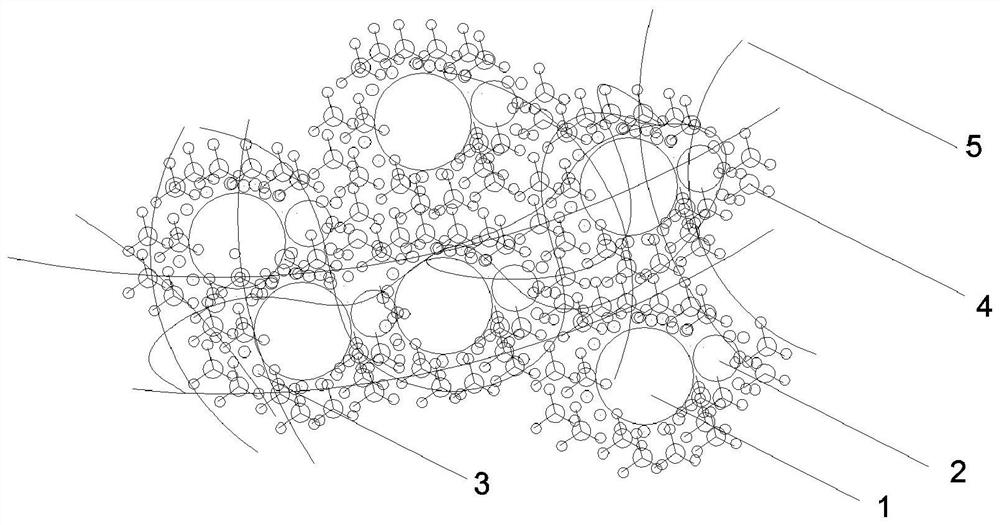

[0076] In the preparation method of the lithium ion battery negative electrode material provided by the present invention, the conductive agent and the conductive enhancer are sequentially coated on the outer surface of the mixture of the carbon-coated negative electrode material and the hard carbon from the inside to the outside, which can improve the obtained lithium ion battery negative electrode material. Conductivity helps to improve the rapid charge and discharge performance of lithium-ion batteries.

[0077] In some embodiments, the conductive agent includes long-chain conductive carbon black and branched-chain conductive carbon black. The conductive carbon black and the conductive enhancer are added in sequence and stirred. In the embodiment of the present invention, by selecting a specific conductive agent and a conductive enhancer, and sequentially coating the conductive agent and the conductive enhancer on the outer surface of the mixture of the carbon-coated negati...

Embodiment 1

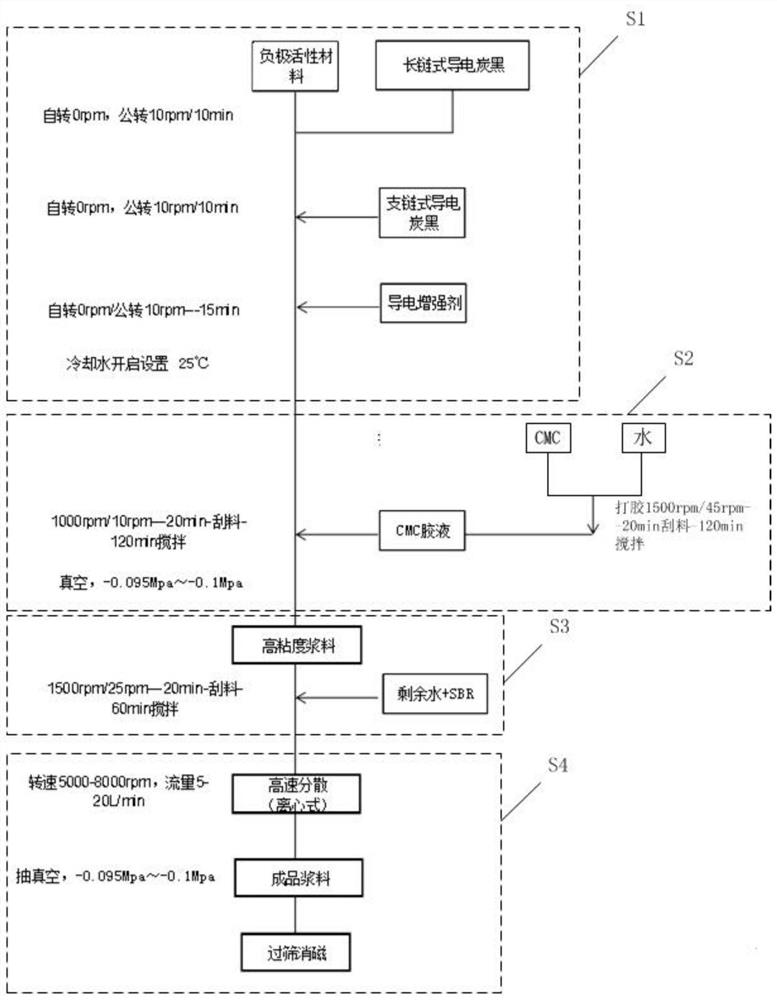

[0082] A lithium ion battery negative electrode material, the preparation method comprising the following steps:

[0083] 1) Glue: First, mix carboxymethyl cellulose and deionized water according to the mass ratio of 1:99, fully stir for 120min (scraping material during stirring for 20min) with a rotation speed of 1500rpm and a revolution speed of 45rpm to prepare a glue solution, Among them, carboxymethyl cellulose accounts for 1.2% of the total mass of lithium-ion battery anode materials;

[0084] 2) dry mixing: the hard carbon-coated artificial graphite and hard carbon are mixed according to a mass ratio of 60:40 to obtain a mixture, and the mixture accounts for 93% of the total mass of the negative electrode material of the lithium ion battery;

[0085] 3) Add conductive agent 1: Add the long-chain conductive carbon black and the mixture obtained in step 2) into the stirring tank, and stir at a revolution speed of 10 rpm for 10 min, so that the long-chain conductive carbon...

Embodiment 2

[0101] This example is basically the same as Example 1, except that in the preparation process of the negative electrode material of the lithium ion battery, the hard carbon-coated artificial graphite and hard carbon in step 2) are mixed according to a mass ratio of 62:38.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com