Silicon-based negative electrode of lithium ion battery and method for preparing silicon-based negative electrode of lithium ion battery

A lithium-ion battery and negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory stress, lack, and influence of adhesion, and achieve improved power performance, excellent elasticity, and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

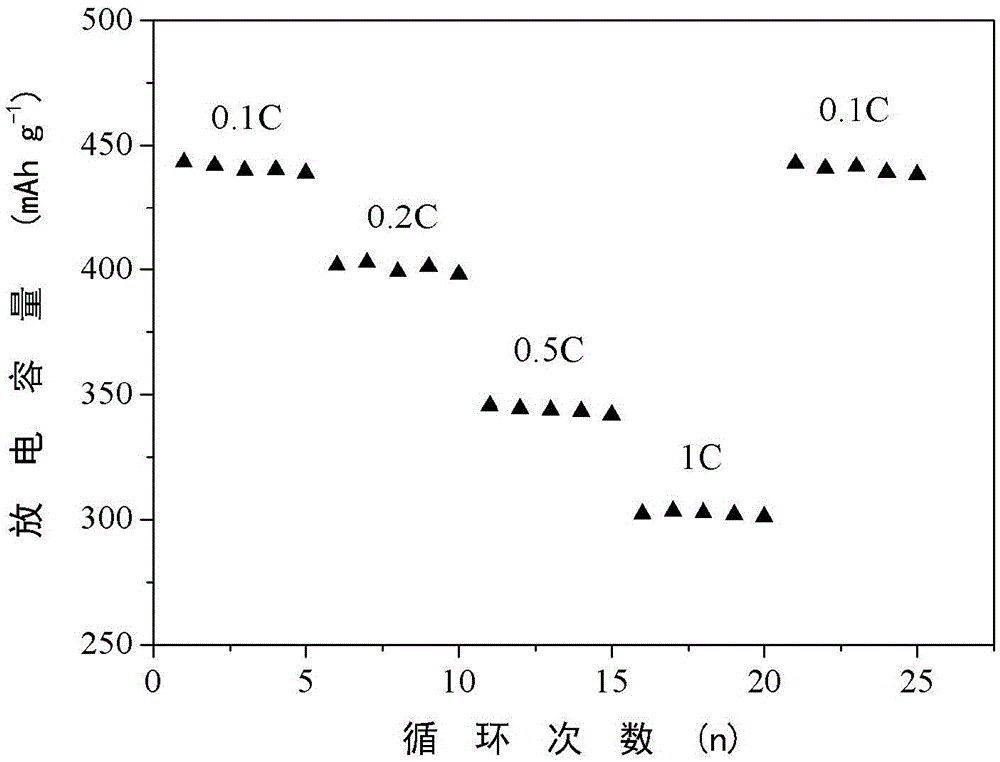

Image

Examples

Embodiment 1

[0044]Coating the negative electrode slurry of the lithium ion battery on the copper foil to prepare the negative electrode of the lithium ion battery has a thickness of 50 microns. The weight ratio formula of each raw material in the slurry is: 15.0 parts by weight of graphite, 2.0 parts by weight of nano silicon powder, 2.5 parts by weight of conductive agent, 5.0 parts by weight of binder, 1.0 parts by weight of sodium carboxymethyl cellulose, deionized water 70.0 parts by weight. The particle size of the graphite is 300 mesh, and the fixed carbon content is more than or equal to 99.8%; the average diameter of the nano silicon powder is about 50 nanometers; the conductive agent is SuperP; the binder is polystyrene-polybutylacrylate - Polystyrene block copolymer latex, the molecular weight of the block copolymer is 15k-100k-15k, and the solid content of the latex is 35%.

[0045] The lithium-ion battery negative electrode slurry is prepared by the following processing techn...

Embodiment 2

[0048] Coating the negative electrode slurry of the lithium ion battery on the copper foil to prepare the negative electrode of the lithium ion battery has a thickness of 300 microns. The weight ratio formula of each raw material in the slurry is: 18.0 parts by weight of graphite, 1.0 parts by weight of nano silicon powder, 0.3 parts by weight of conductive agent, 8.0 parts by weight of binder, 1.5 parts by weight of sodium carboxymethyl cellulose, and 80.0 parts by weight of deionized water parts by weight. The particle diameter of described graphite is 400 orders, and fixed carbon content is more than or equal to 99.5%; The average diameter of nano-silicon powder is 80 nanometers; Described conductive agent is SuperS; Described binding agent is polystyrene-polybutylacrylate- Polystyrene block copolymer latex, the molecular weight of the block copolymer is 50k-150k-50k, and the solid content of the latex is 15%.

[0049] The lithium-ion battery negative electrode slurry is p...

Embodiment 3

[0052] Coating the negative electrode slurry of the lithium ion battery on the copper foil to prepare the negative electrode of the lithium ion battery has a thickness of 50 microns. The weight ratio formula of each raw material in the slurry is: graphite: 15 parts by weight, nano silicon powder 2 parts by weight, conductive agent 2.0 parts by weight, binder 1.0 parts by weight, sodium carboxymethyl cellulose 1.0 parts by weight, deionized water 80.0 parts by weight. The particle size of the graphite is 500 mesh, and the fixed carbon content is more than or equal to 99.9%; the average diameter of the nano silicon powder is about 100 nanometers; the conductive agent is carbon nanotubes; the binder is polystyrene-polyacrylic acid Butyl ester-polystyrene block copolymer latex, the molecular weight of the block copolymer is 15k-40k-15k, and the solid content of the latex is 30%.

[0053] The lithium-ion battery negative electrode slurry is prepared by the following processing tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com