A kind of modified lithium titanate electrode material and preparation method thereof

An electrode material, lithium titanate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of limited performance improvement of LTO, and achieve the effects of low cost, improved electronic conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a modified lithium titanate electrode material, comprising the following steps:

[0029] (1) Lithium dihydrogen phosphate, phenolic resin and solvent are mixed to obtain a suspension;

[0030] (2) Evaporate to dryness and grind after mixing the suspension and lithium titanate to obtain powder;

[0031] (3) In an inert atmosphere, heat-treat the powder to obtain the modified lithium titanate electrode material.

[0032] In the present invention, the mass ratio of lithium dihydrogen phosphate and phenolic resin in the step (1) is preferably 1-10: 1-10, more preferably 2-8: 2-8, more preferably 4-6: 4~6.

[0033] In the present invention, the solid content of the suspension in the step (1) is preferably 0.1-1 g / L, more preferably 0.2-0.8 g / L, more preferably 0.4-0.6 g / L.

[0034] In the present invention, two materials are used for simultaneous coating, and the two coating materials can exert synergistic benefits, that is, ...

Embodiment 1

[0049]Mix phenolic resin, lithium dihydrogen phosphate and ethanol to obtain 0.5L of a suspension with a solid content of 0.5g / L. The mass ratio of phenolic resin to lithium dihydrogen phosphate is 1:1; then add 5g of Lithium titanate, the particle size of lithium titanate is 500nm, stirred at 450rpm for 4 hours; then evaporated to dryness at 60°C, all the ethanol was evaporated, and ground at 60rpm for 3h after evaporation to obtain powder;

[0050] The powder was placed in a nitrogen atmosphere and heat-treated at 750° C. for 2 hours to obtain a modified lithium titanate electrode material.

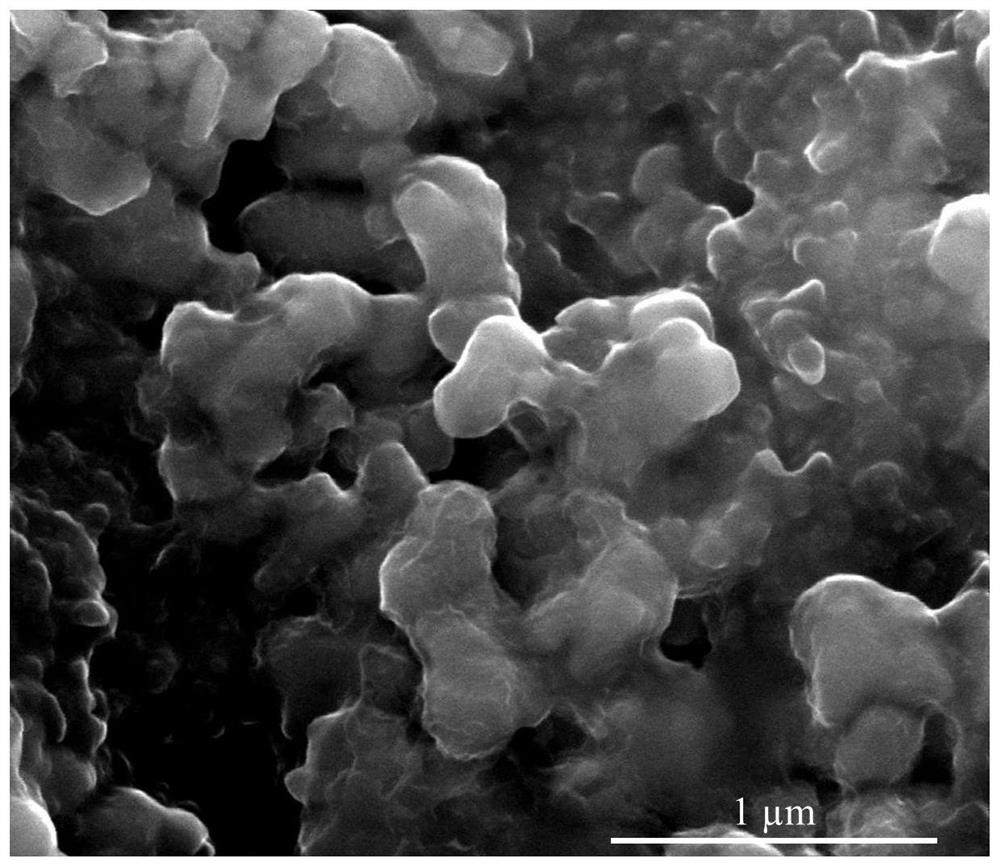

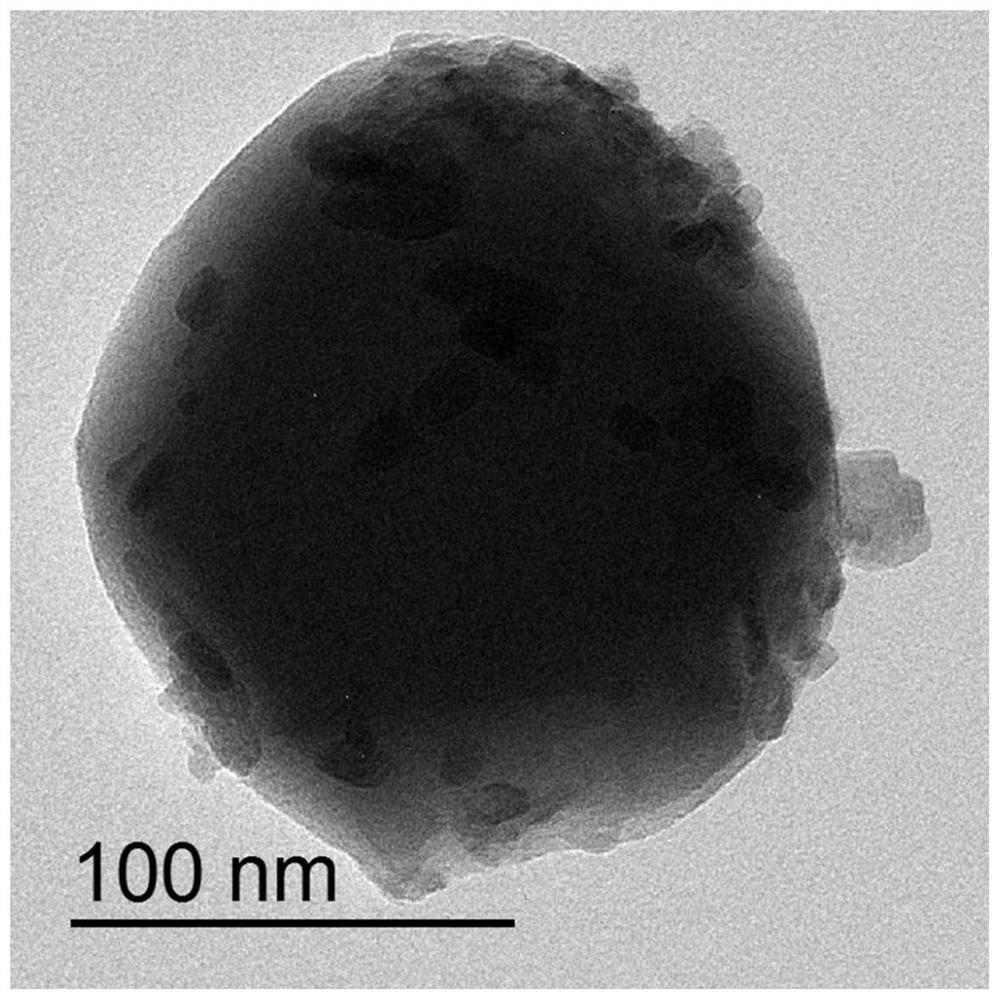

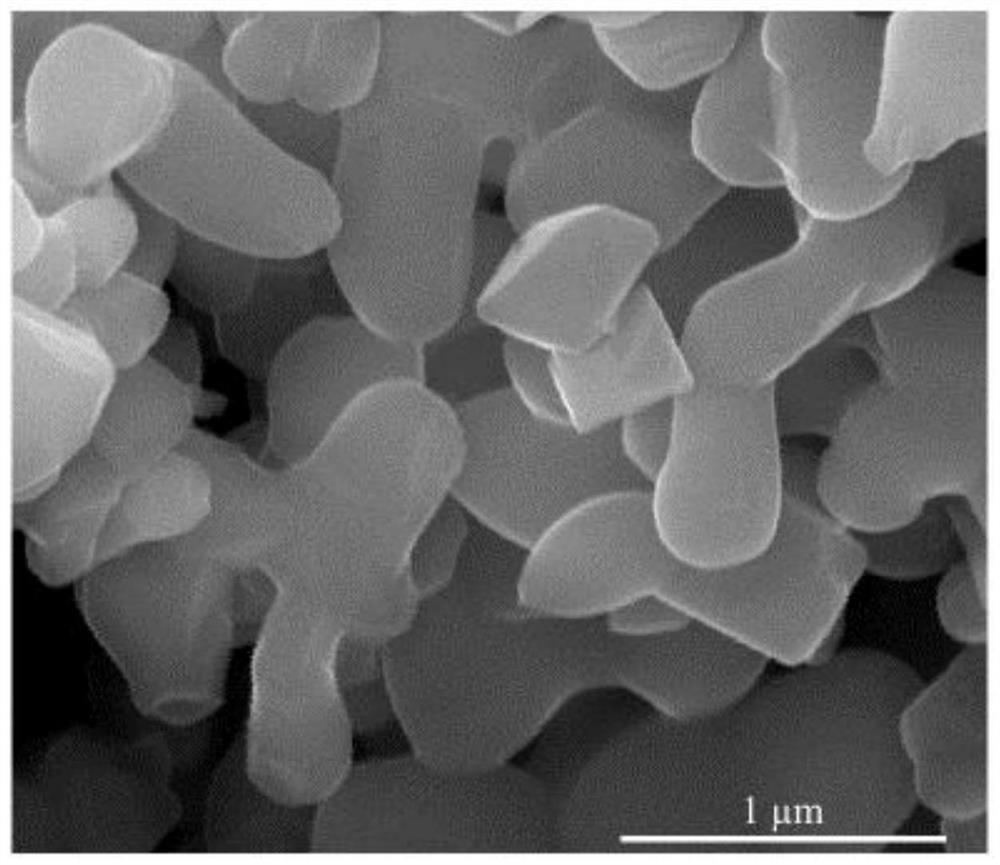

[0051] The modified lithium titanate electrode material prepared in this example was observed, figure 1 It is the SEM picture of the modified lithium titanate electrode material, figure 2 is the TEM image of the modified lithium titanate electrode material, from figure 1 with figure 2 It can be clearly seen that there are obvious coatings on the surface of the modified lithium tita...

Embodiment 2

[0062] Mix phenolic resin, lithium dihydrogen phosphate and ethanol to obtain 1L of a suspension with a solid content of 0.8g / L, and the mass ratio of phenolic resin to lithium dihydrogen phosphate is 2:1; then add 20g of Lithium titanate, the particle size of lithium titanate is 400nm, stirred at 500rpm for 5 hours; then evaporated to dryness at 70°C, all the ethanol was evaporated, and ground at 50rpm for 3h after evaporation to obtain powder;

[0063] The powder was placed in a nitrogen atmosphere and heat-treated at 700° C. for 2.5 hours to obtain a modified lithium titanate electrode material.

[0064] Assemble the button battery: Weigh 0.425g of the obtained modified lithium titanate composite negative electrode material, add 0.05g of acetylene black as a conductive agent and 0.025g of LA-132 as a binder, and grind and mix them evenly in an agate mortar to make an electrode The slurry was uniformly coated on the aluminum foil, and dried in a vacuum oven at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com