Pre-plating process of chemically-plated Ni-P alloy

An alloy process and electroless plating technology, which is applied in the direction of liquid chemical plating, metal material coating process, magnetic materials, etc., can solve the problems of poor bonding between the coating and the magnet, affecting the close combination of the coating and the substrate, and peeling of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

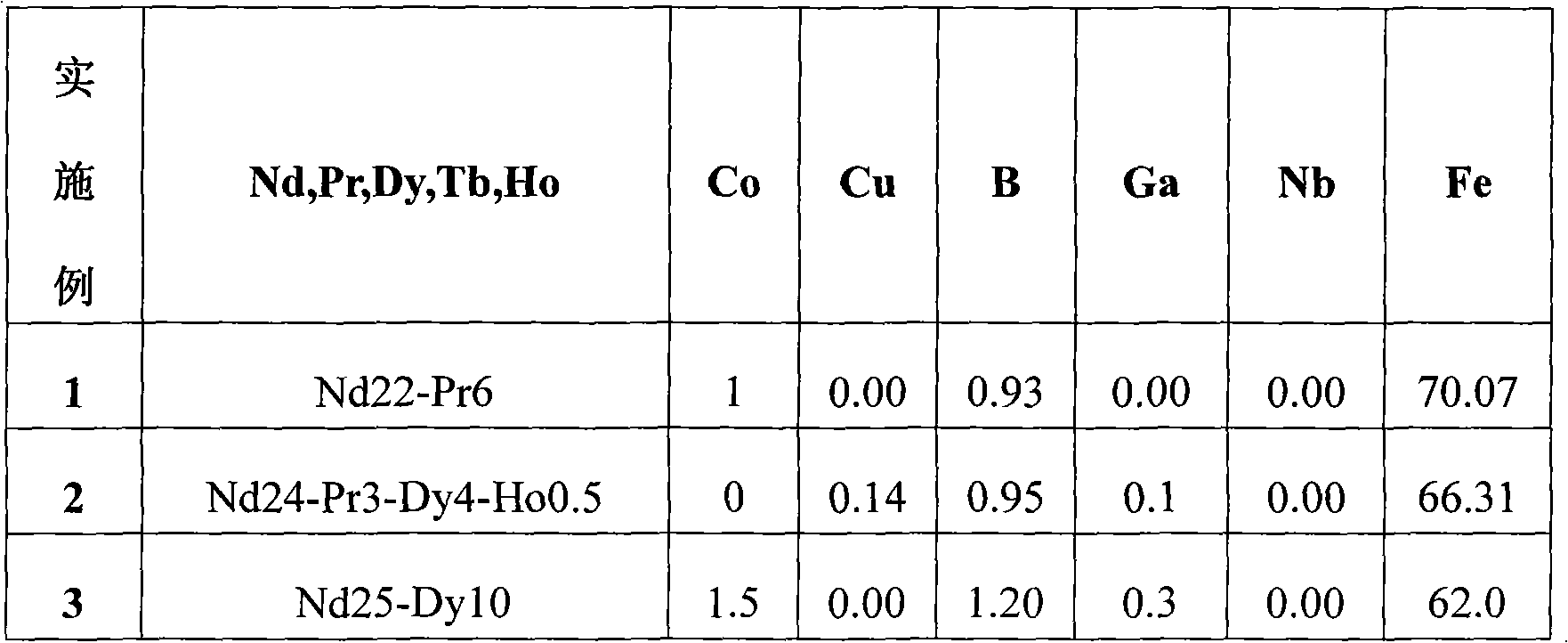

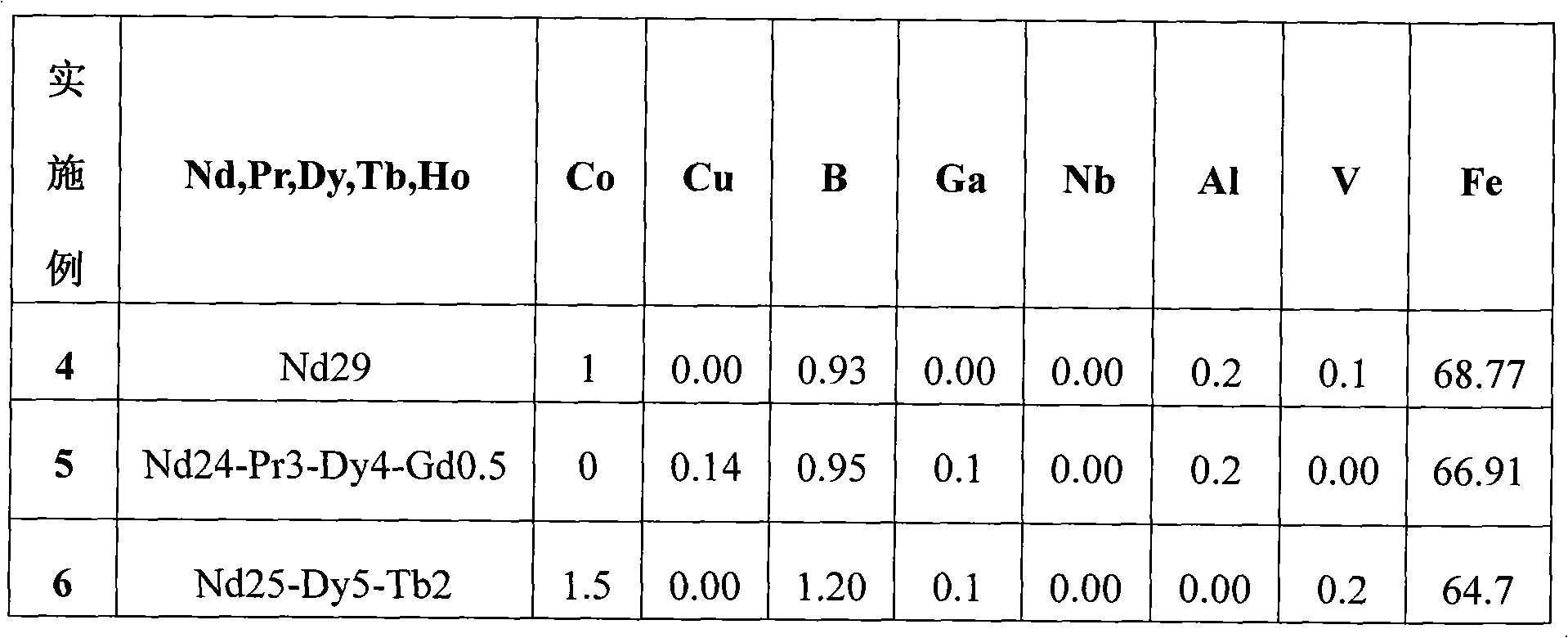

Examples

Embodiment 1

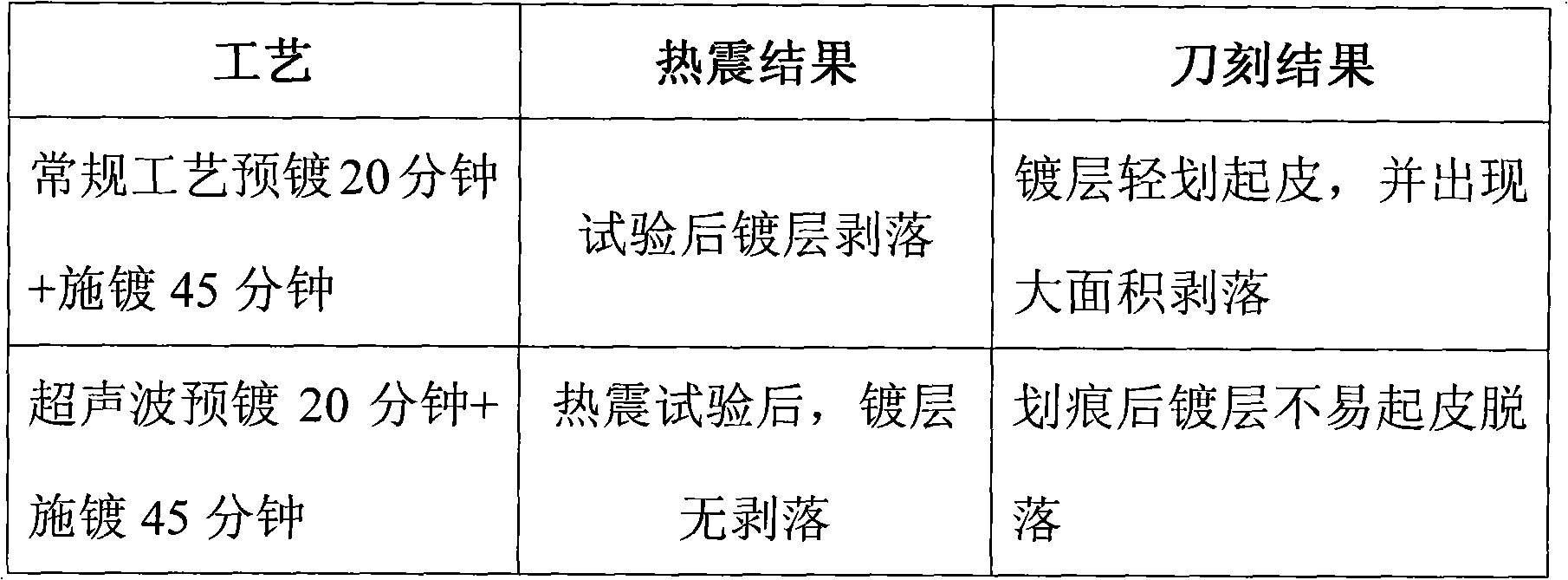

[0025] Prepare sample D10.5*2.5, where 2.5 is the direction of magnetization, and the density of the sample is 7.4g / cm 3 , using the conventional process for pre-plating for 20 minutes and ultrasonic pre-plating for 20 minutes, wherein the frequency of ultrasonic pre-plating is 40kHz, the power of ultrasonic pre-plating is 110W, and the temperature of ultrasonic pre-plating is 56°C. After 45 minutes, the finished product was evaluated by thermal shock test and knife engraving test, and the results are shown in Table 1

[0026] Table 1

[0027]

[0028] From the results, after 20 minutes of ultrasonic pre-plating, the bonding force between the substrate and the coating can be improved.

Embodiment 2

[0030] Prepare sample D12.5*2.5, where the 2.5 direction is the magnetization direction, and the density of the sample is 7.5g / cm 3 , using the conventional process for pre-plating for 30 minutes and ultrasonic pre-plating for 30 minutes respectively, wherein the frequency of ultrasonic pre-plating is 50kHz, the power of ultrasonic pre-plating is 90W, and the temperature of ultrasonic pre-plating is 60°C. After plating for 45 minutes, thermal shock and knife engraving tests were used to evaluate the bonding strength of the finished product. The results are shown in Table 2:

[0031] Table 2

[0032]

Embodiment 3

[0034] Prepare sample D12.5*2.5, where the 2.5 direction is the magnetization direction, and the density of the sample is 7.5g / cm 3 , using the conventional process for pre-plating for 25 minutes and ultrasonic pre-plating for 25 minutes, wherein the frequency of ultrasonic pre-plating is 45kHz, the power of ultrasonic pre-plating is 100W, and the temperature of ultrasonic pre-plating is 57°C. After 45 minutes of plating, the finished product was evaluated by thermal shock and knife engraving experiments, and the results are shown in Table 3:

[0035] table 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com