Glucosidase/xylosidase difunctional cellulose degradation enzyme RuGBGX2 as well as coding gene and application thereof

A technology of glucosidase and xylosidase, applied in the field of glucosidase/xylosidase dual-functional cellulose degrading enzyme and its preparation, can solve the problem of weak natural cellulose hydrolysis ability, low activity of insoluble cellulose, and cellulose production Bioenergy and other issues, to achieve the effect of large industrial prospects and value, broad industrial application prospects, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 The construction of Chinese yak rumen microbial metagenomic DNA library

[0042] The rumen contents of 2 Chinese Qinghai yaks were collected from a slaughterhouse in Xining City, filtered through three layers of gauze, the filtrate was centrifuged to collect rumen microbial cells, and frozen at -80°C until use. Take 100-200ul bacterial sample, wash 2-3 times with 1ml PBS, add 650uL DNA extraction buffer (Tris-HCl, 100mMpH8.0; Na 2 EDTA 100mM pH8.0; Na 3 PO 4 Buffer 100mM pH8.0; NaCl 1.5M; CTAB 1%; pH8.0), mix well, place in -80℃, then place in 65℃ water bath to melt, repeat three times; add 3-4μL lysozyme after cooling ( 100mg / L) shake horizontally (37°C, 225rpm) in a shaker for about 30min; add 2-3μL proteinase K (20mg / mL) and continue shaking for about 30min; add 50-70uL SDS (20%), mix well, Incubate at 65°C for 1-2h, invert the centrifuge tube up and down every 10-20min to mix; centrifuge at 12,000rpm for 10min at room temperature, collect the supernatan...

Embodiment 2

[0045] Example 2 Cloning and sequence analysis of RuBGX2 gene derived from rumen microorganisms

[0046] The 16C12 glucosidase / xylosidase gene was cloned into the pGEM11z vector by subcloning: the cosmid plasmid of the screened positive clone 16C12 was cut into 2-5kb fragments with the Sau3A I part, and then ligated into the pGEM11z vector which was digested with BamHI and Transform DH5a into the dephosphorylated pGEM11z vector, and perform functional screening on the subcloned library by the method described in Example 1. The obtained subclones were sequenced with T7 and SP6 universal primers, and the β-1, 4 - the coding region sequence of the glucosidase gene, its gene nucleotide sequence is as shown in SEQ ID NO 1, and is named as RuBGX2.

[0047] The RuBGX2 gene cds encodes 755 amino acids, the ORF sequence is shown in SEQ ID NO 2, and the theoretical molecular weight is 82.4kD. Using SMART to analyze the structural domain, it shows that the 18 amino acids from the N-term...

Embodiment 3

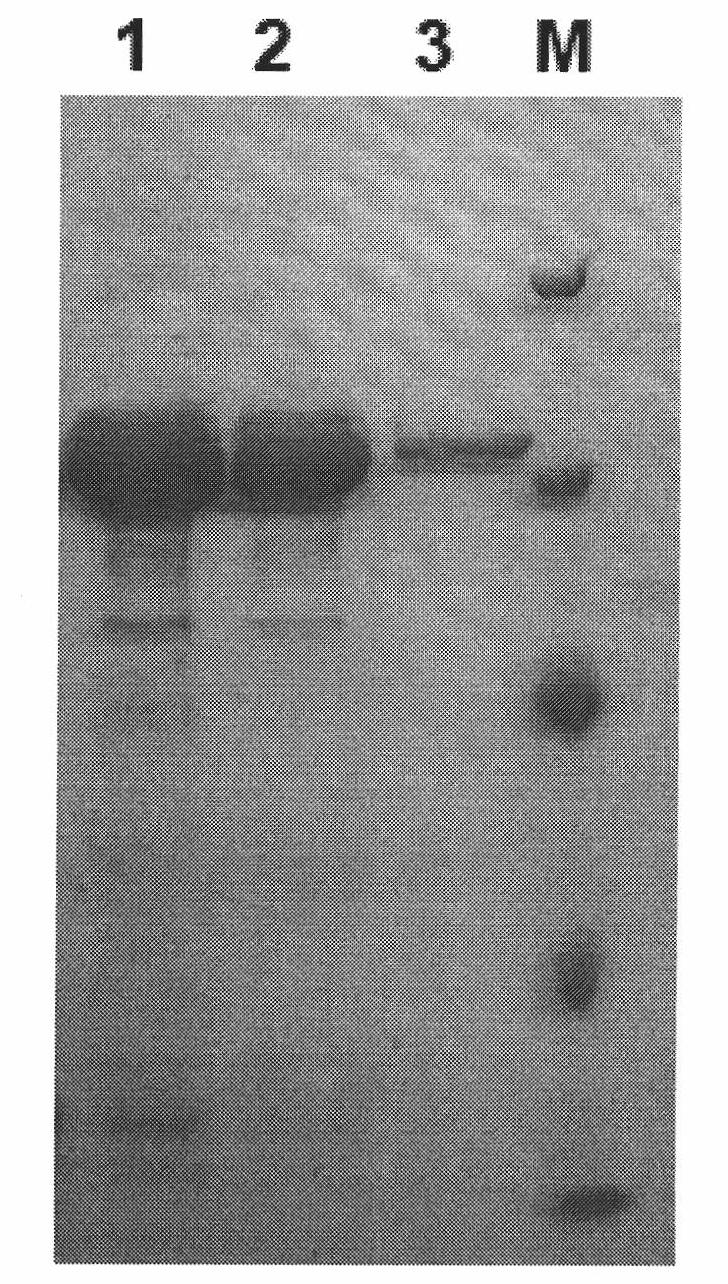

[0048] Recombinant expression of embodiment 3 RuBGX2 gene in escherichia coli

[0049] In order to clone the cds sequence of RuBGX2 gene into Escherichia coli expression vector pET-21a for recombinant expression, a pair of primers were designed: the forward primer sequence is RuBGX2F:AAT GAATTC ATGAAAGCAATCCTTACAACC, reverse primer is RuBGX2R:TAT AAGCTTTAGCGTCACAGTCACGTTC, the underlined restriction enzyme sequence. The RuBGX2 gene fragment was amplified by PCR reaction. After gel recovery, it was digested with EcoR I and HindIII. After the fragment was recovered, it was ligated with the pET-21a vector that was also digested with EcoR I and HindIII. The ligated product was transformed into E. coli Top10 Bacterial strains, the obtained transformants were identified by cooking PCR using the above primers, and the transformants containing 2.3kb amplified fragments were detected for enzyme activity and sequenced for identification, and the correct transformants were named Top10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com