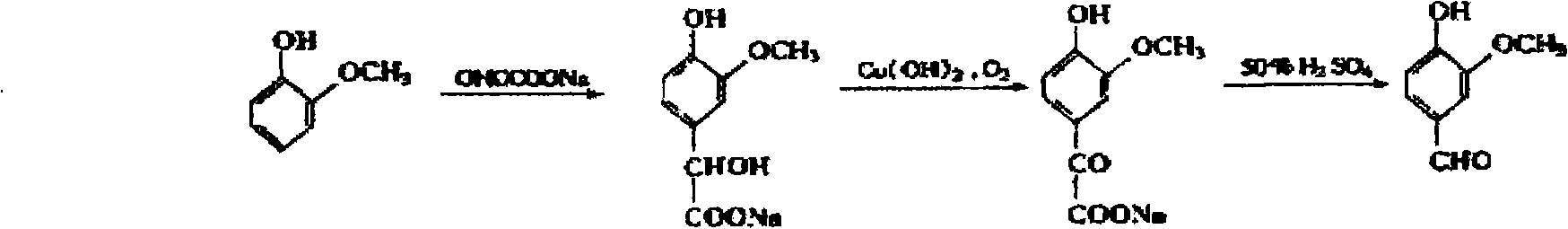

Method for synthesizing vanillin by using glyoxylic acid and guaiacol together

A technology of guaiacol and glyoxylic acid, applied in the field of medicine and chemical industry, can solve the problems of huge investment in production equipment, long process flow, high cost of raw materials and environmental protection costs, reduce production costs, simplify production processes, and improve the utilization of raw materials. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Catalyst preparation: Weigh 7.5g (0.03mol) of reagent copper sulfate, 3.4g (0.02mol) of reagent manganese sulfate and 2.4g (0.01mol) of reagent cobalt sulfate, and dissolve them in 100m deionized water to prepare a metal salt solution. Y-type molecular sieve (benzene absorption ≥ 230mg / g; mechanical strength ≥ 80%; SiO 2 / Al 2 o 3 ≥4.5) 100g is added to the above metal salt solution and soaked for 30 minutes, add 5% sodium hydroxide solution to pH11, vacuum filter and separate molecular sieve, wash with a small amount of deionized water, dry at 105°C, and oxidize in a high-temperature furnace at 550°C Bake for 60 minutes and set aside.

[0033] Synthesis of vanillin: Install a 1000mL four-necked reaction bottle equipped with an air distributor, reflux condenser, stirrer and three constant pressure dropping funnels on a constant temperature water bath, and add 74.1g (0.4mol) 40% glyoxylic acid, 59.5g (0.48mol) guaiacol and 100mL 30% liquid caustic soda. Add 500 mL of...

Embodiment 2

[0036] 74.1g (0.4mol) of 40% glyoxylic acid, 52.1g (0.42mol) of guaiacol and 100mL of 30% liquid caustic soda were respectively added to the three constant pressure dropping funnels of the reactor of Example 1. Add 500 mL of deionized water and 106.6 g (0.8 mol) of 30% liquid caustic soda into a four-necked reaction flask, and add 5.0 g of the catalyst prepared in Example 1, stir and blow in air, and the air pressure is 0.05 Mpa. After the solution was heated to 80°C, glyoxylic acid, guaiacol and alkali solution were added dropwise to the reaction flask simultaneously, the dropping speed of glyoxylic acid and guaiacol was controlled at 10mL / h, and the 3-methoxy The concentration of the base-4-hydroxymandelic acid intermediate is less than 2.0%, and the dropping speed of the alkali solution is controlled to make the pH of the solution 11-13. The raw material solution was dropped in about 6 hours, then the temperature was raised to 100° C., stirring was continued and air was blo...

Embodiment 3

[0039] 74.1g (0.4mol) of 40% glyoxylic acid, 52.1g (0.42mol) of guaiacol and 100mL of 30% liquid caustic soda were respectively added to the three constant pressure dropping funnels of the reactor of Example 1. Add 500 mL of deionized water and 106.6 g (0.8 mol) of 30% liquid caustic soda into a four-necked reaction flask, and add 5.0 g of the catalyst prepared in Example 1, stir and blow in air, and the air pressure is normal pressure. After the solution was heated to 80°C, glyoxylic acid, guaiacol and alkali solution were added dropwise to the reaction flask simultaneously, the dropping speed of glyoxylic acid and guaiacol was controlled at 10mL / h, and the 3-methoxy The concentration of the base-4-hydroxymandelic acid intermediate is less than 2.0%, and the dropping speed of the alkali solution is controlled to make the pH of the solution 11-13. The raw material solution was dropped in about 10 hours, then the temperature was raised to 100° C., the stirring and air blowing w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com