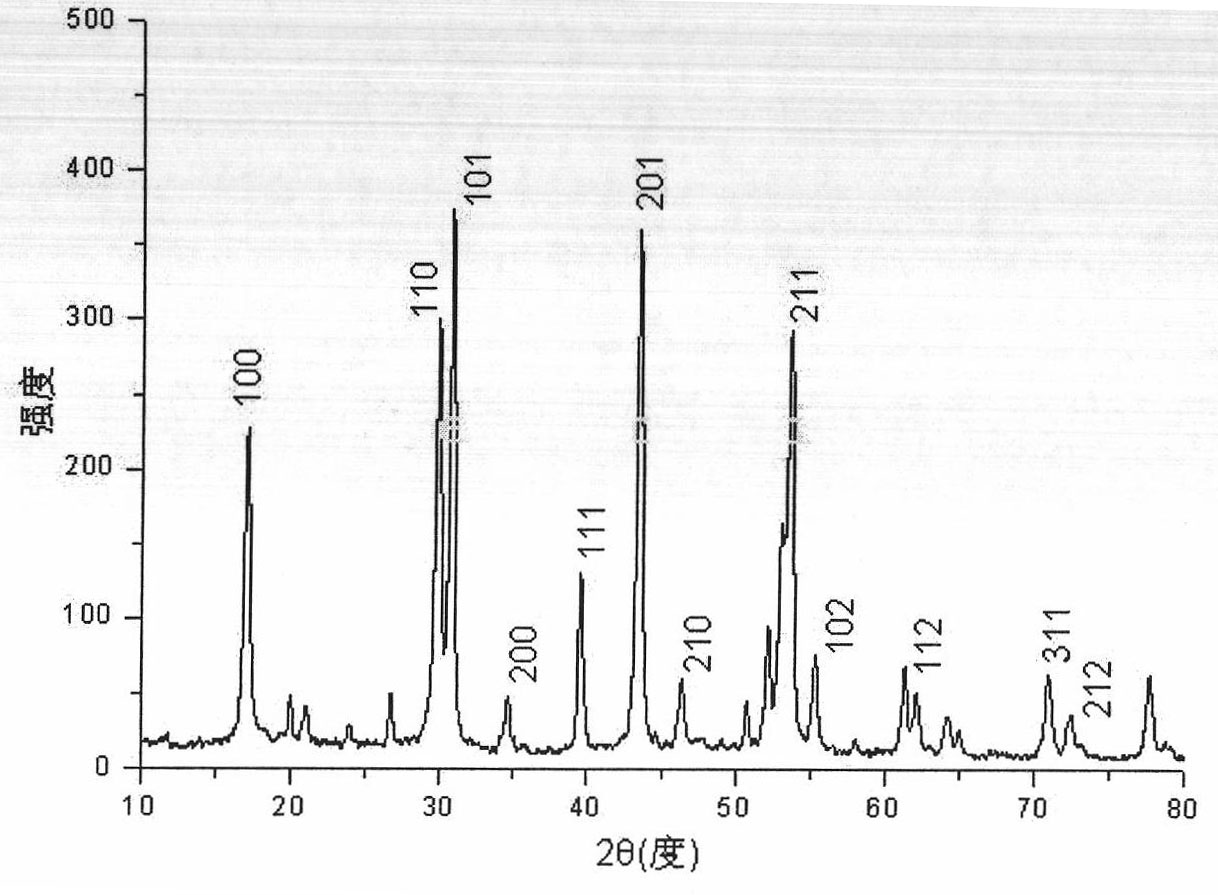

Method for preparing polychromatic luminous nanocrystalline of monodisperse NaYF4

A technology of sodium tetrafluoroyttrium and nanocrystals is applied in the field of preparation of monodisperse sodium tetrafluoroyttrium multicolor luminescent nanocrystals to achieve the effect of good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

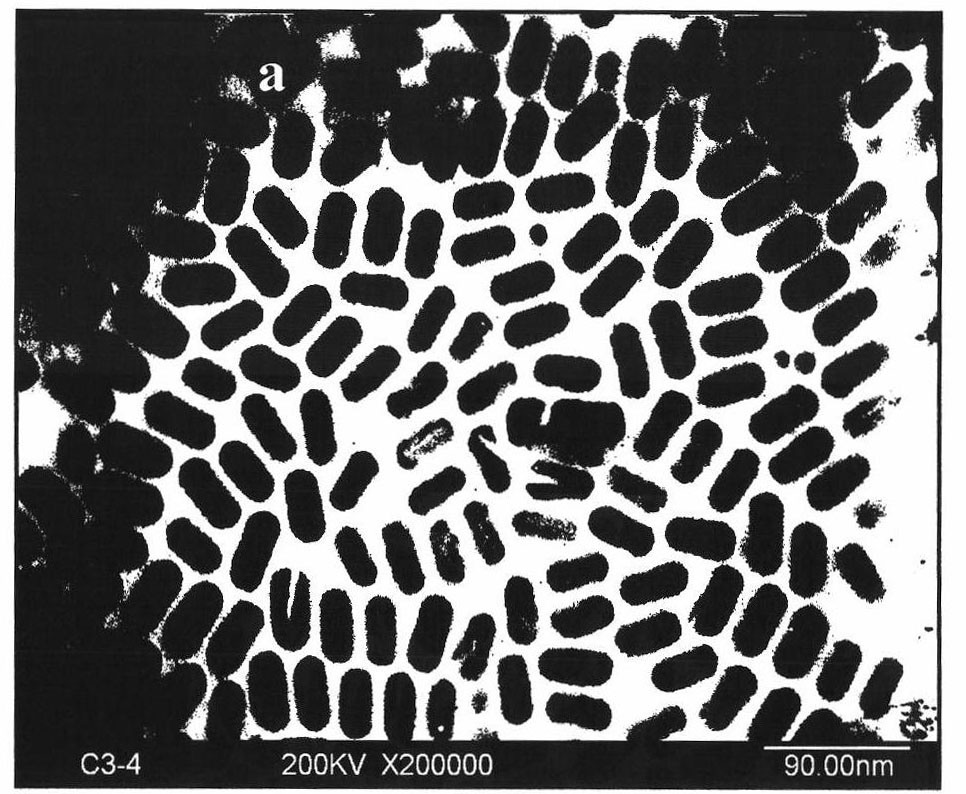

Embodiment 1

[0026] 1. Take by weighing 0.04mol yttrium nitrate hexahydrate, 0.0075mol ytterbium nitrate hexahydrate and 0.0025mol erbium nitrate hexahydrate respectively with an electronic balance, make 100ml uniform solution with deionized water, and its total rare earth concentration is 0.5mol / L, And the molar ratio between the rare earth elements is Y:Yb:Er=80:15:5;

[0027] 2. Add 3ml of oleic acid, 4ml of absolute ethanol, dropwise 6ml of 1.5mol / L NaOH aqueous solution, 15ml of cyclohexane, and 10ml of the rare earth solution prepared in step 1 into a 50ml reaction kettle. After fully stirring, put it into the kettle React at 80°C for 4 hours. After the reaction is over, use a 25ml pipette to separate the water and oil phases, discard the water phase in the reaction solution, and dilute the upper oil phase to 20ml with cyclohexane to obtain rare earth precursors. body

[0028] 3. Slowly add 3ml of hydrofluoric acid, 3ml of cyclohexane, and finally 7ml of absolute ethanol dropwise in...

Embodiment 2

[0033] 1. Take by weighing 0.025mol yttrium nitrate hexahydrate, 0.0249mol ytterbium nitrate hexahydrate and 0.0001mol erbium nitrate hexahydrate respectively with an electronic balance, and make 100ml uniform solution with deionized water, and its total rare earth concentration is 0.5mol / L, And the molar ratio between the rare earth elements is Y:Yb:Er=50:49.8:0.2;

[0034] 2. Add 3ml of oleic acid, 4ml of absolute ethanol, dropwise 6ml of 1.5mol / L NaOH aqueous solution, 15ml of cyclohexane, and 10ml of the rare earth solution prepared in step 1 into a 50ml reaction kettle. After fully stirring, put it into the kettle React at 80°C for 4 hours. After the reaction is over, use a 25ml pipette to separate the water and oil phases, discard the water phase in the reaction solution, and dilute the upper oil phase to 20ml with cyclohexane to obtain rare earth precursors. body

[0035] 3. Slowly add 3ml of hydrofluoric acid, 3ml of cyclohexane, and finally 7ml of absolute ethanol dr...

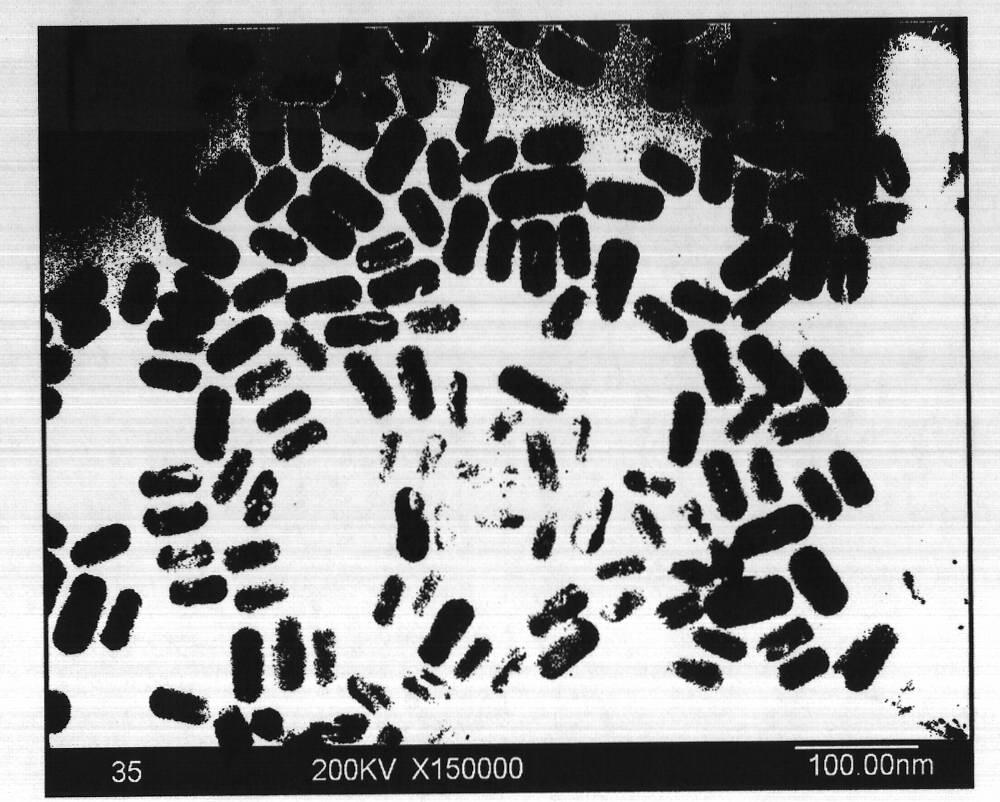

Embodiment 3

[0040] 1. Take by weighing 0.03mol yttrium nitrate hexahydrate, 0.0199mol ytterbium nitrate hexahydrate and 0.0001mol erbium nitrate hexahydrate respectively with an electronic balance, make 100ml uniform solution with deionized water, and its total rare earth concentration is 0.5mol / L, And the molar ratio between the rare earth elements is Y:Yb:Er=60:39.8:0.2;

[0041] 2. Add 3ml of oleic acid, 4ml of absolute ethanol, dropwise 6ml of 1.5mol / L NaOH aqueous solution, 15ml of cyclohexane, and 10ml of the rare earth solution prepared in step 1 into a 50ml reaction kettle. After fully stirring, put it into the kettle React at 80°C for 4 hours. After the reaction is over, use a 25ml pipette to separate the water and oil phases, discard the water phase in the reaction solution, and dilute the upper oil phase to 20ml with cyclohexane to obtain rare earth precursors. body

[0042] 3. Slowly add 3ml of hydrofluoric acid, 3ml of cyclohexane, and finally 7ml of absolute ethanol dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com