Method and device for producing natural ultrathin stone by using combination saw

An ultra-thin, stone technology, used in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as easy breakage, and achieve the effects of easy control, high degree of automation, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

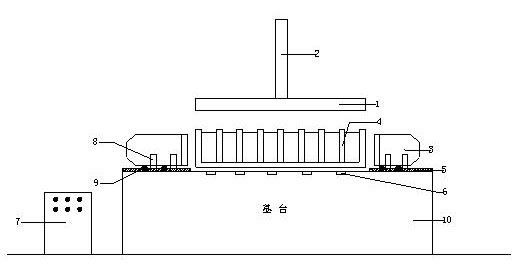

[0021] according to figure 1 As shown, the abutment 10 is a rectangle poured with reinforced concrete, with a height of 40-60cm and a length x width of 10 x 5m. The horizontal slideway 5 and the vertical slideway 6 are vertically intersected on the horizontal platform, hydraulically regulated The template 3 is installed on the horizontal slideway 5 through the bottom plate, and can move left and right along the horizontal slideway 5. It is controlled by the hydraulic device of the microcomputer controller 7 to move forward and backward. Its general size is 1800×600×500mm. ×1200×600mm; the composite partition 4 is installed on the vertical slideway 6, and can move back and forth along the vertical slideway 6; the composite partition 4 is made of several metal corrosion-resistant steel plates with a thickness of 30mm, and the 5mm hard plastic inner lining, its function is to minimize the vibration caused by the sawing process and ensure the yield; the width of the combined part...

Embodiment 2

[0024] 1. Process the granite block into 2~3cm thick wool board;

[0025] 2. According to the needs of the product, further adopt methods such as double-sided fire or polishing, machine planing, etc., to process the raw board into finished thick boards with various surface forms that meet the decoration requirements. The specifications of the boards are generally 600×1800㎜, or larger 1200×2400㎜, the thickness of the board is 30㎜, and the thickness tolerance is ±1㎜;

[0026] 3. Place the processed finished thick plate on the composite partition 4 and fix it on the corresponding position in the processing area of the abutment 10 through the vertical slide 6, start the hydraulic control template 3, and fix it closely with the composite partition 4 through the horizontal track 5 , through the control arm 2, the combined knife saw 1 is aligned with the plate in the combined partition 4. After calibration, the fixture 8 is put down and locked to the hydraulic control template 3, a...

Embodiment 3

[0029] Granite blocks 1.8*1*0.6 as an example

[0030] The processing steps are as follows:

[0031] 1. Cut the granite blocks 600×1800×1000㎜ into rough boards of 600×1800×(23×35);

[0032] 2. Polish or burn both sides of the wool board to make a finished board of 600×1800×(20-30);

[0033] 3. Use the cutting device of the present invention to process the finished boards into 600×1800×(5-8) ultra-thin stone veneers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com