Naphthenic filling oil for soft plastic toys and preparation method thereof

A naphthenic and extended oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of low product yield, environmental pollution, anti-exudation, anti-yellowing, non-toxic and odorless It is difficult to meet the performance requirements and other problems, to achieve the effect of improving product quality and performance, overcoming large environmental pollution, and making the preparation process and use performance safe and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Cut naphthenic crude oil through conventional atmospheric and vacuum distillation to obtain distillate oil with an acid value of less than 0.5 mgKOH / g and a distillation range of 350°C to 500°C, and carry out hydrotreating of the distillate oil at a reaction temperature of 350°C and a reaction pressure of 6.5MPa , hydrogen oil volume ratio 1000:1, space velocity 1.0h -1 , the catalyst is KL-12, and the oil product after medium-pressure hydrotreating is obtained, and the fraction at 300°C to 400°C is fractionated, and then this fraction is subjected to solvent refining. The solvent is N-methylpyrrolidone, and the solvent ratio is 1.5:1 , the extraction temperature is 70°C, and finally the solvent-refined raffinate is subjected to hydrogenation supplementary refining, the reaction temperature is 210°C, the reaction pressure is 9.5MPa, the hydrogen-oil volume ratio is 500:1, and the space velocity is 0.5h -1 , the catalyst is KL-1, after the above-mentioned combined proces...

Embodiment 2~6

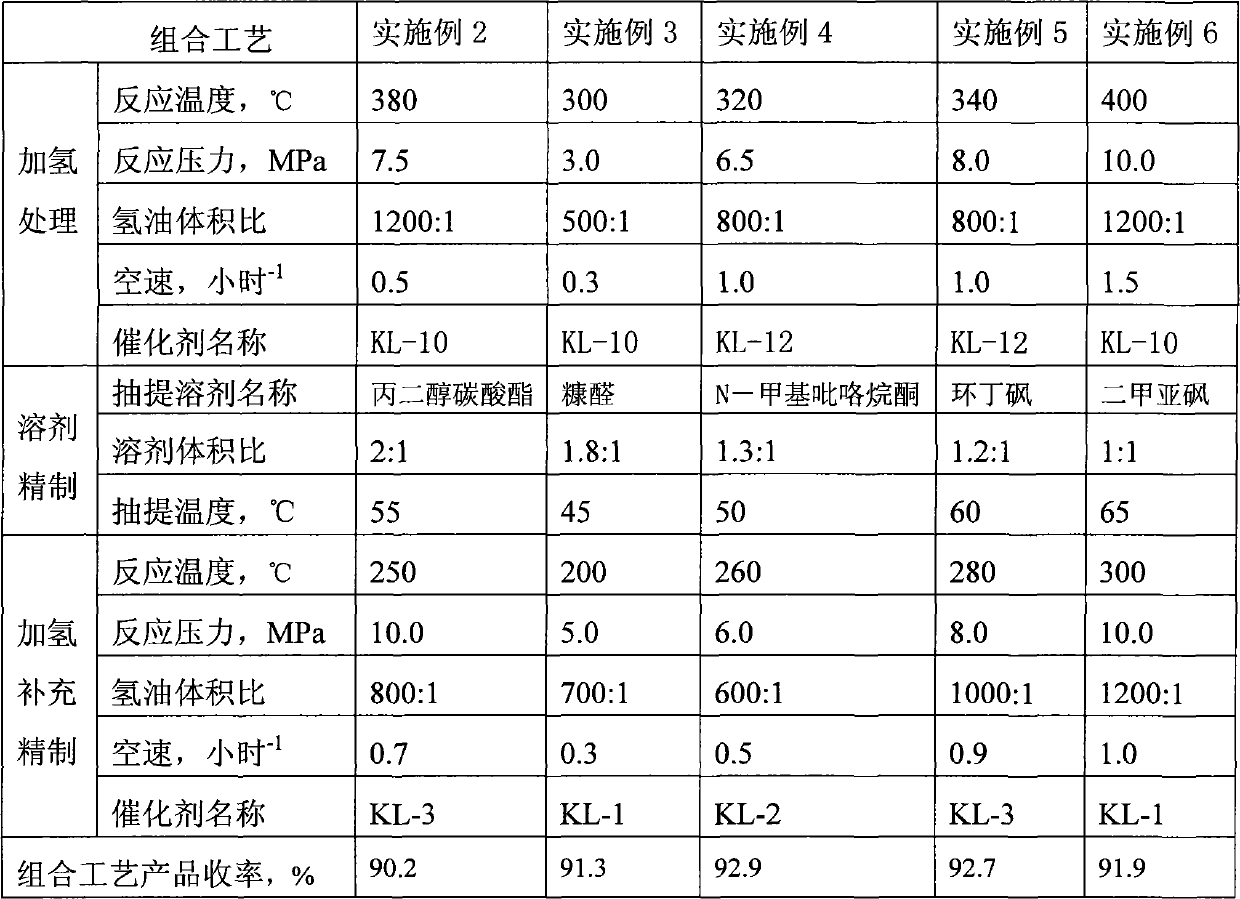

[0030] It is the preparation example of naphthenic filler oil for soft rubber toys, and its preparation implementation process is the same as that of Example 1, but the combined process conditions are different, as shown in Table 3. Table 4 shows the analysis results of the naphthenic-based filler test oil prepared in the corresponding examples, and Table 5 shows the test results of the odor and yellowing resistance of the naphthenic-based filler oils prepared in the corresponding examples.

[0031] Table 3 Process conditions for the preparation of naphthenic extender oil for soft rubber

[0032]

[0033] Table 4 Analysis of Physicochemical Properties of Naphthenic Extender Oil

[0034]

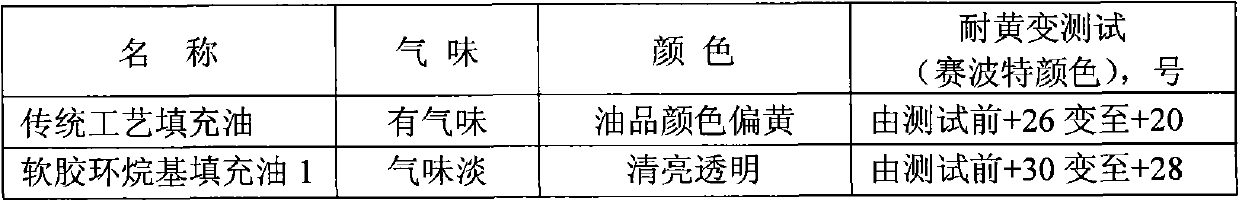

[0035] The cycloalkyl extender oil smell and anti-yellowing test result prepared by the corresponding embodiment of table 5

[0036] name

[0037] Example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com