Method for preparing high-purity copper oxide superfine powder from waste printed circuit boards

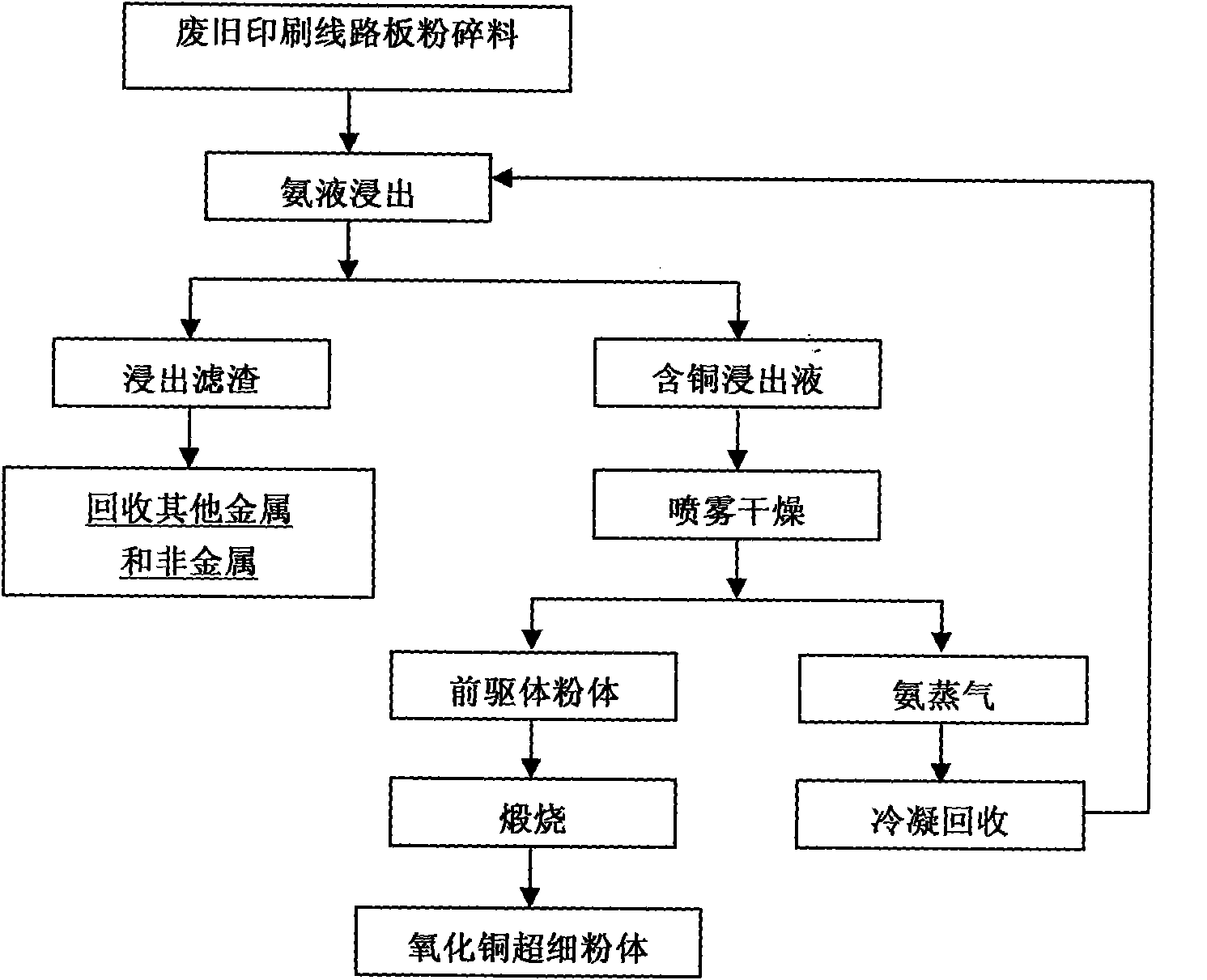

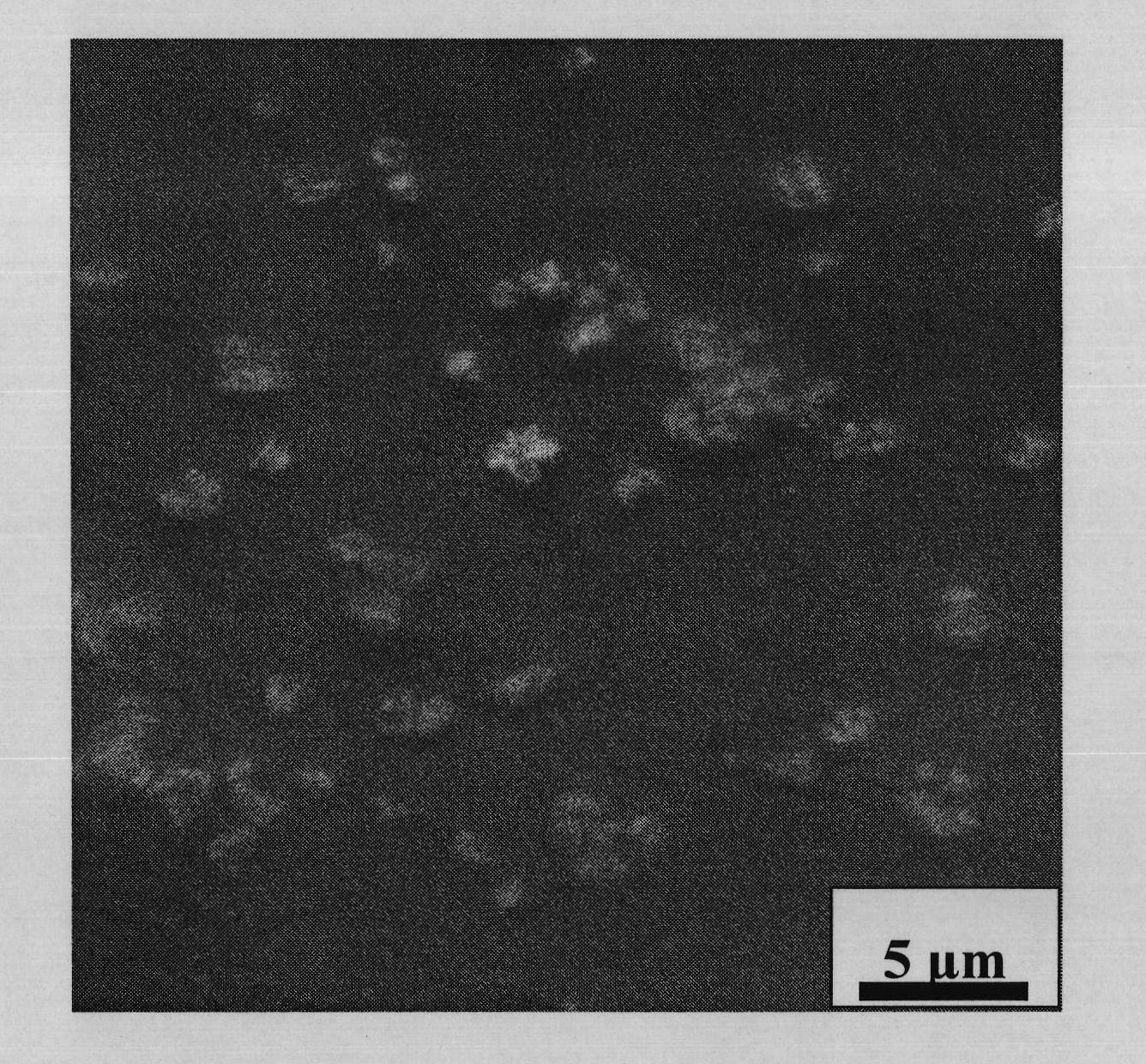

A technology of waste printed circuit and printed circuit board, which is applied in the field of electronic waste recycling, can solve the problems of strong acid corrosion equipment, harmful gas secondary pollution, etc., and achieve the effect of small average particle size and narrow particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of crushed waste printed circuit boards: manually crush waste printed circuit boards into fragments smaller than 10cm×10cm, and then crush them with a strong plastic crusher and a sealed sample preparation grinder to obtain crushed waste printed circuit boards material, the particle size of the waste printed circuit board pulverized material is 10 mesh;

[0022] 2) Preparation of copper-containing leaching solution: take 10 g of the waste printed circuit board pulverized material obtained in step 1) and immerse in ammonia water, add hydrogen peroxide dropwise to the leaching solution at room temperature and under stirring with an electromagnetic stirrer, control the reaction time to 10 hours, wait After the reaction is over, take out the waste material and carry out solid-liquid separation, and the obtained filtrate is the copper-containing leaching solution, wherein the mass ratio of the waste printed circuit board pulverized material, hydrogen peroxide a...

Embodiment 2

[0026] 1) Preparation of crushed waste printed circuit boards: manually crush waste printed circuit boards into fragments smaller than 10cm×10cm, and then crush them with a strong plastic crusher and a sealed sample preparation grinder to obtain crushed waste printed circuit boards Material, the particle diameter of described scrap printed circuit board pulverized material is 30 orders;

[0027] 2) Preparation of copper-containing leaching solution: take 10 g of the waste printed circuit board pulverized material obtained in step 1) and immerse in ammonia water, add hydrogen peroxide dropwise to the leaching solution at room temperature and under stirring with an electromagnetic stirrer, control the reaction time to 8 hours, wait After the reaction finishes, take out the waste material, carry out solid-liquid separation, and the obtained filtrate is the copper-containing leaching solution, wherein the mass ratio of waste printed circuit board pulverized material, hydrogen perox...

Embodiment 3

[0031] 1) Preparation of crushed waste printed circuit boards: manually crush waste printed circuit boards into fragments smaller than 10cm×10cm, and then crush them with a strong plastic crusher and a sealed sample preparation grinder to obtain crushed waste printed circuit boards material, the particle size of the waste printed circuit board pulverized material is 60 mesh;

[0032] 2) Preparation of copper-containing leaching solution: take 10 g of the waste printed circuit board pulverized material obtained in step 1) and immerse in ammonia water, add hydrogen peroxide dropwise to the leaching solution at room temperature and under the condition of stirring with an electromagnetic stirrer, control the reaction time to 9 hours, wait After the reaction is over, take out the waste material and carry out solid-liquid separation, and the obtained filtrate is the copper-containing leaching solution, wherein the mass ratio of waste printed circuit board pulverized material, hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com