Receiving module package method for optical interconnection on chip

A receiving module and packaging method technology, applied in the direction of optical waveguide light guide, electrical components, circuits, etc., can solve the problems of low integration, high cost, and inability to use chips for shorter distance communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

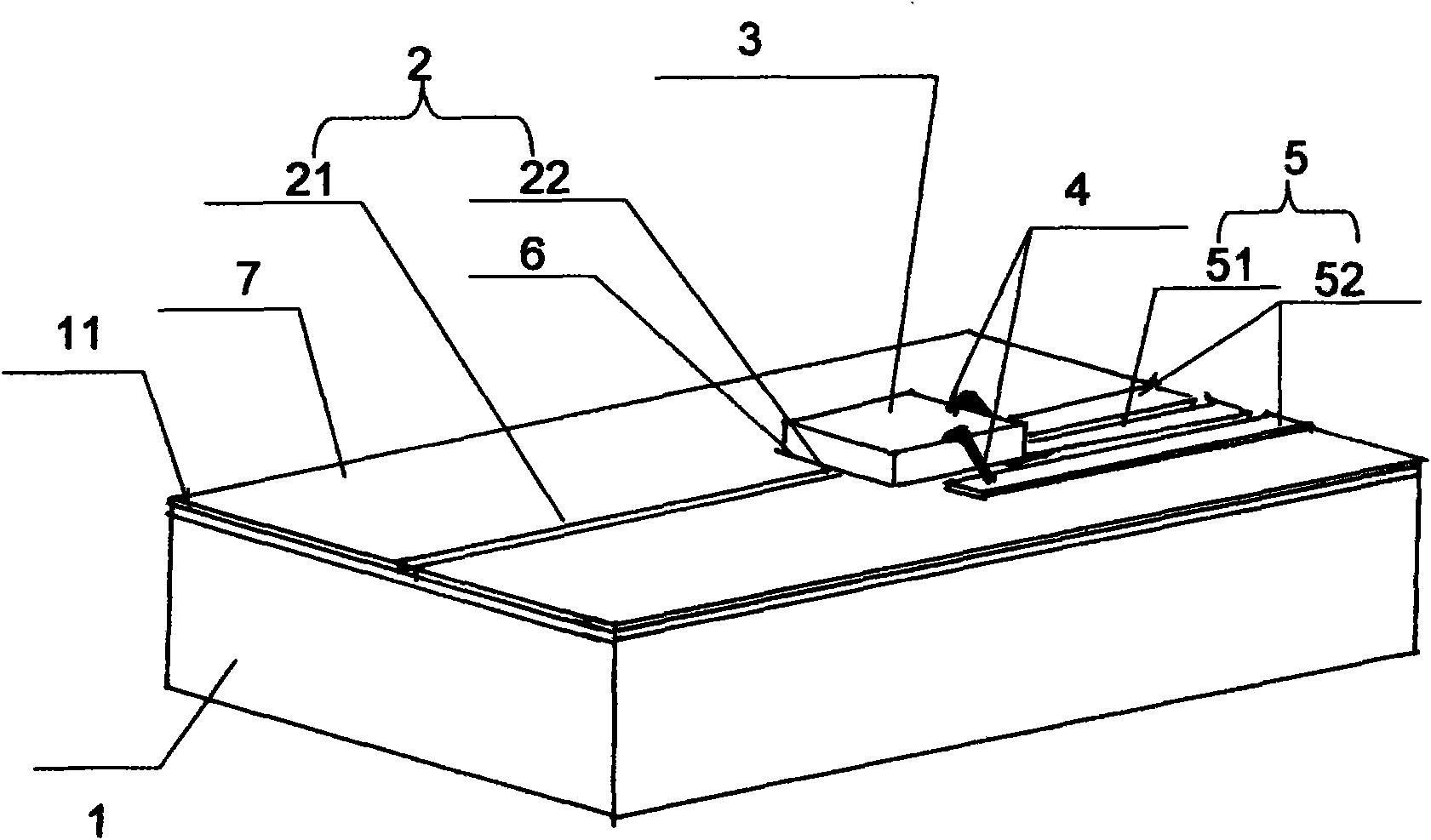

[0025] see figure 1 , a receiving module packaging method for on-chip optical interconnection, the method includes the following manufacturing steps:

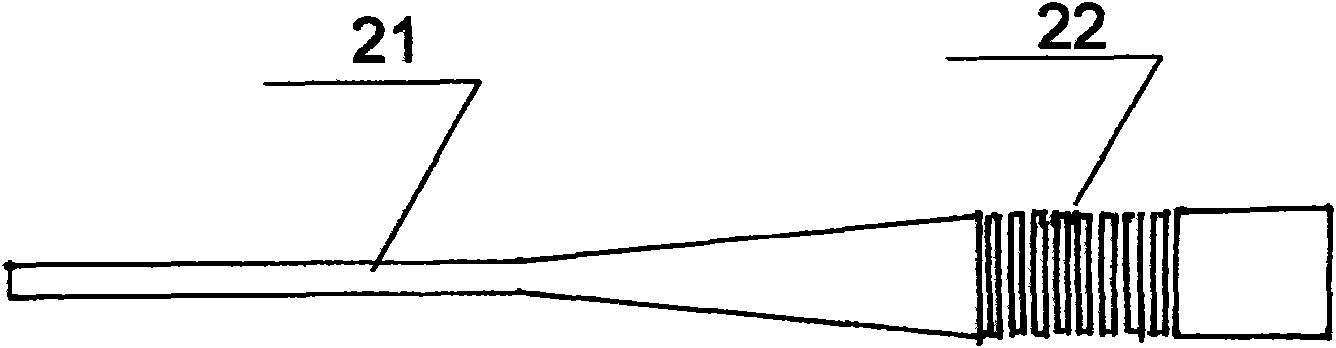

[0026] Step 1: First, clean the SOI substrate 1 to remove organic and inorganic impurities on the substrate, and then evenly coat the electron beam photoresist on the surface of the SOI substrate 1 through a coater. Based on methyl acrylate glue (PMMA) photoresist, pre-baking the SOI substrate 1 after coating, the pre-baking temperature is 180 degrees Celsius, and the time is 20 minutes, and then put the SOI substrate 1 into the electron beam exposure machine, Select an appropriate exposure dose to expose the pattern of the grating coupler 2 including the ridge waveguide 21 and the grating structure 22, then develop and fix, and finally perform post-baking on the exposed SOI substrate 1 at a post-baking temperature of 120 degrees Celsius , and the time is 20 minutes. After electron beam exposure, a fine submicron pattern is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com