Method for manufacturing transparent conductive lamination body

A technology of transparent conductivity and manufacturing method, applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of warping expansion coefficient, substrate 11 stress residue, anisotropy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

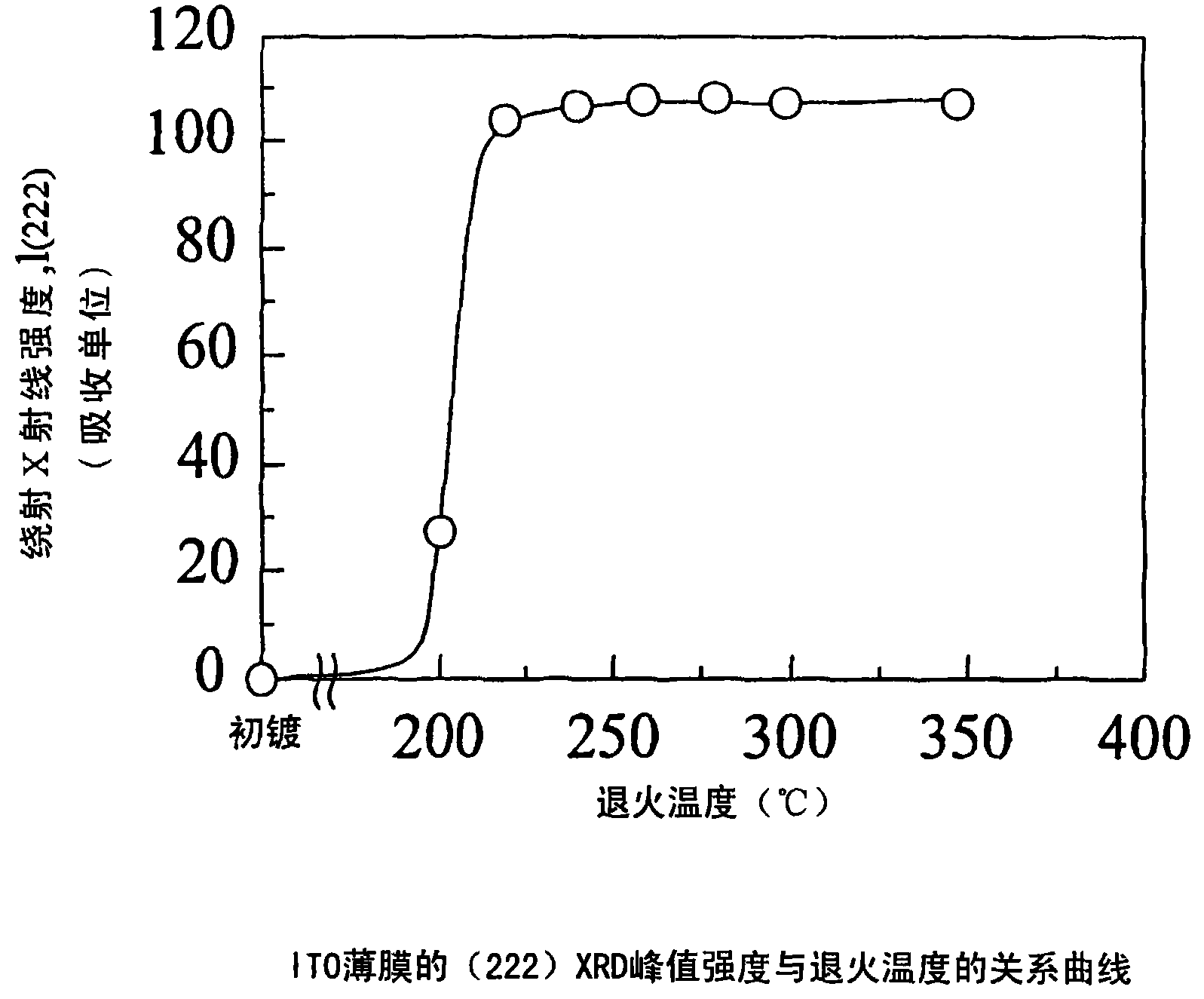

[0017] The present invention relates to a method for manufacturing a transparent conductive laminate. It mainly refers to the manufacturing method of the conductive laminate in the transparent conductive film. The transparent conductive film 2 includes at least one organic polymer substrate 21, and at least one laminate 22 is formed on the surface of the substrate 21, wherein the organic polymer substrate 21 Can include PC, PET... etc., at least one layer of the laminated body 22 can be a conductive layer 221 laminated mainly formed of indium tin oxide (ITO) material, the formation of the conductive layer 221 can be through Vacuum evaporation method, sputtering method, ion coating method, spray pyrolysis method, chemical plating method, electroplating method or their combination method to form, wherein preferred vacuum evaporation method, sputtering method, formed on the surface of substrate 21 After the conductive layer 221, it is irradiated with a light source with a specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com