Water quenching and cooling method and device for ultrahigh-strength strip steel

An ultra-high-strength, cooling device technology, used in quenching devices, furnaces, heat treatment equipment, etc., can solve the problem of not considering the elimination of strip thermal stress and phase transformation stress and uniform cooling, harmful furnace conditions and environment, and poor strip shape. It is easy to correct the shape of the board, the effect is good, and the effect of improving the shape of the board is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

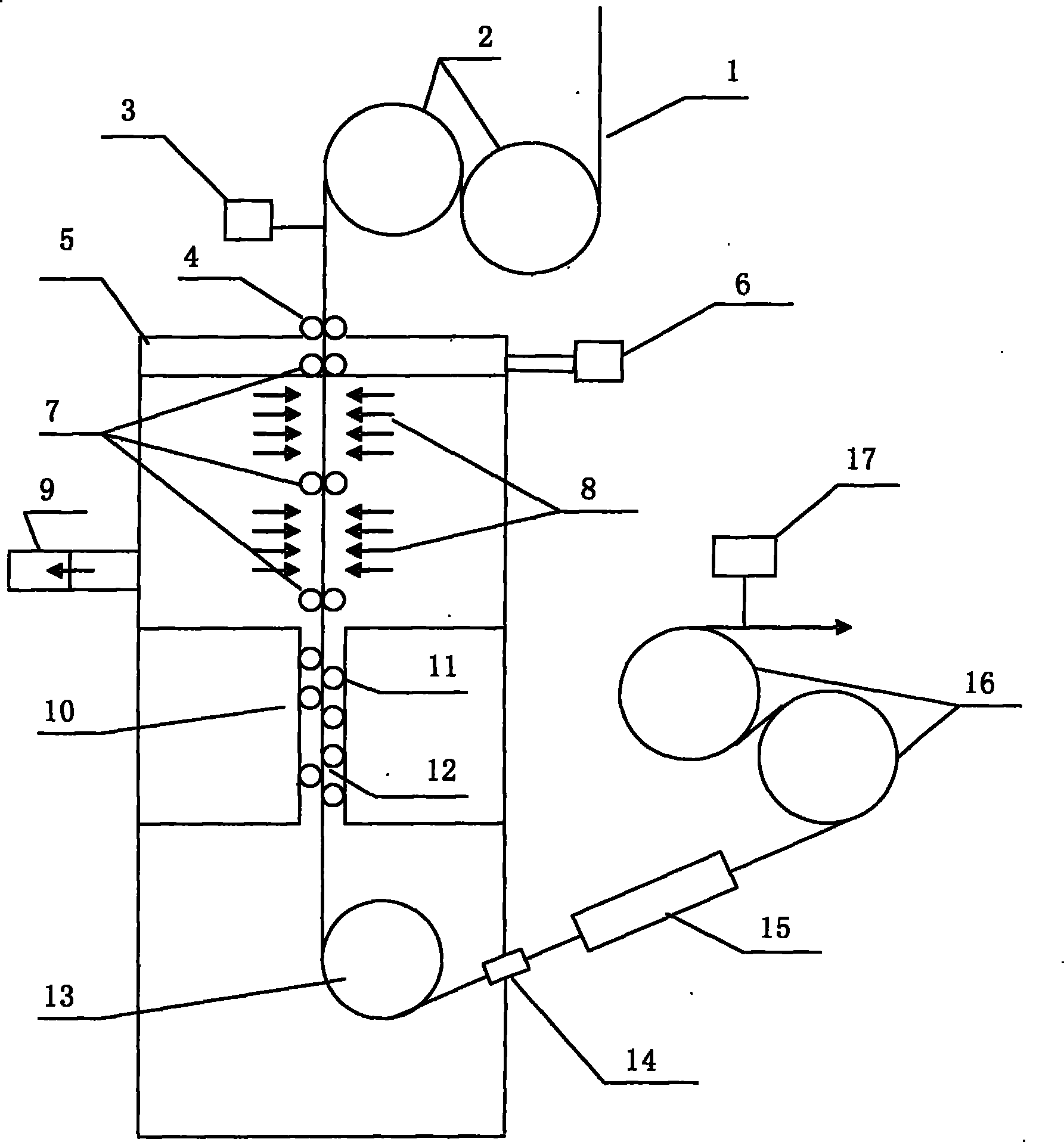

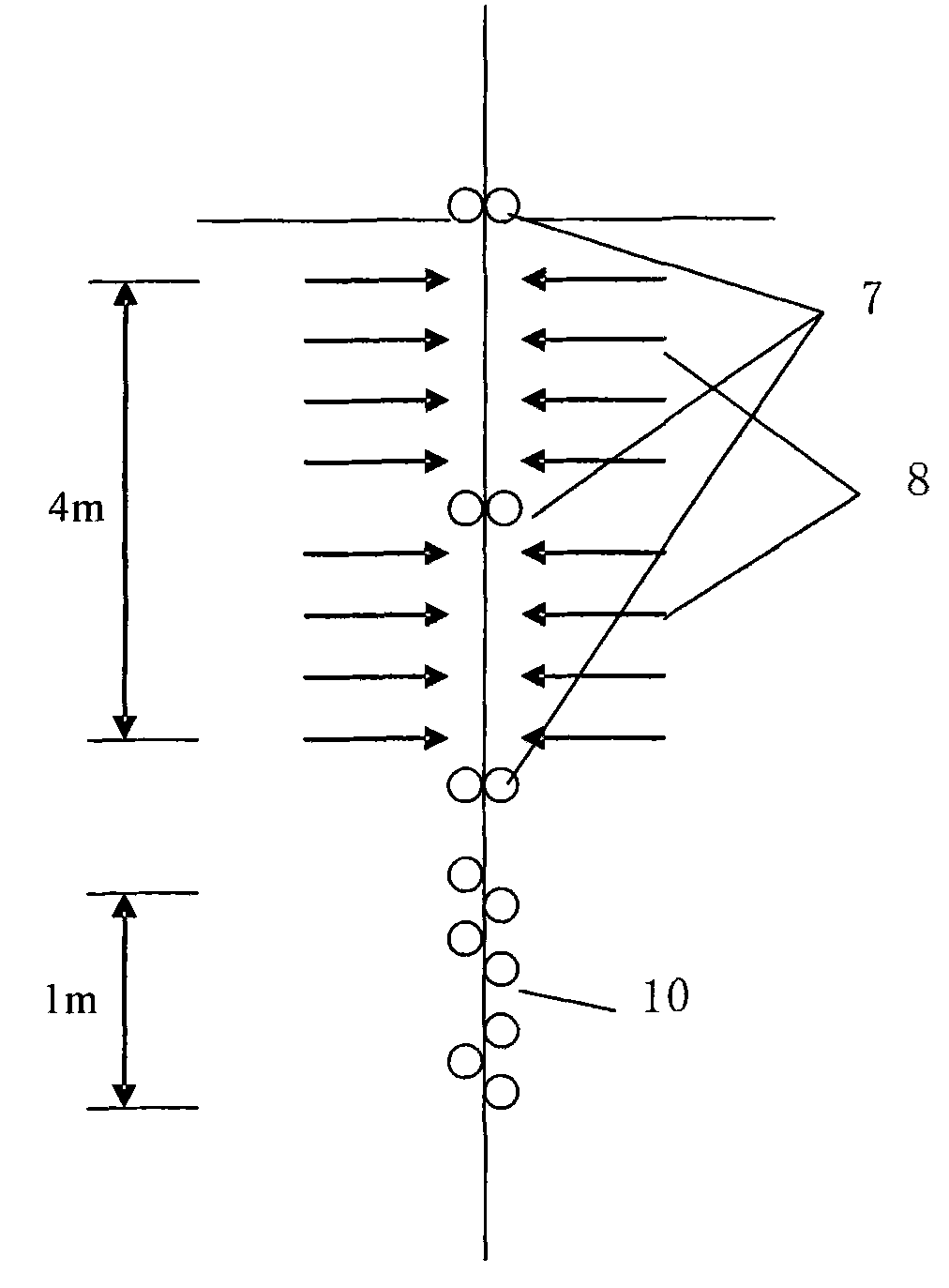

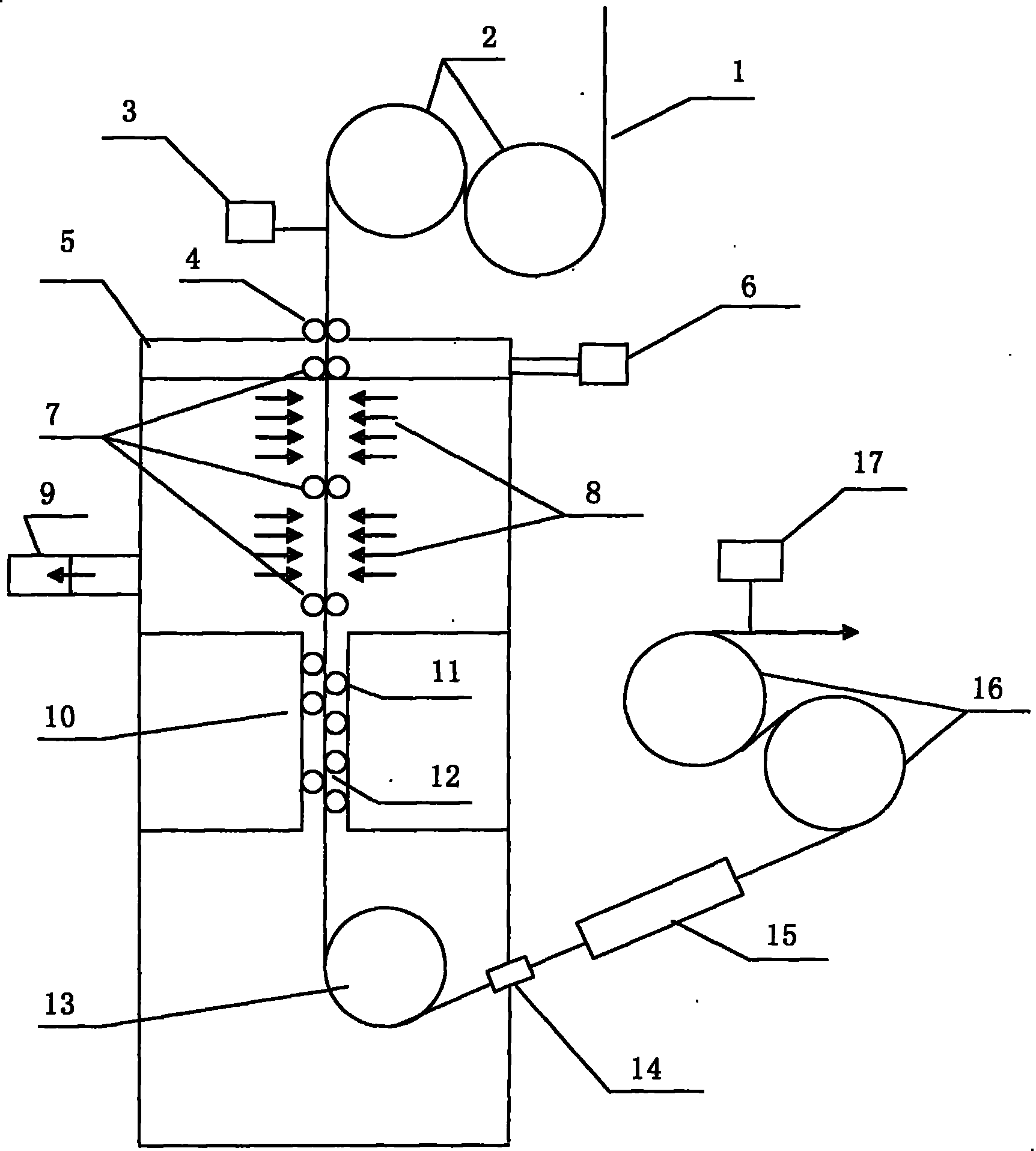

[0049] Example 1, the steel strip to be cooled is 980Mpa dual-phase steel with a thickness of 0.8mm (martensite content is about 30%). When the high-temperature strip steel at about 650°C after soaking and slow cooling enters the water quenching cooling tank 5 of the present invention through the entrance tension roller 2, the gas sealing device 4, etc., the water quenching nozzle 8 sprays 0.7-0.8Mpa desalination at about 60°C. Water cools the strip quickly on the surface of the high-temperature strip in operation, and at the same time, controls the elongation of the tension leveling to about 3-5%, adopts the strip speed V=200mpm=3.3m / s, 8 pairs of high-pressure water-cooled nozzles 8 and two bends and one Straightening and straightening are all invested.

[0050] In this embodiment, by controlling the parameters of high-pressure water cooling, the steel plate is cooled to 320°C, and the warm straightening process is completed after the martensitic transformation occurs, and t...

example 2

[0051] Example 2, the strip steel to be cooled is 1470Mpa martensitic steel with a thickness of 1.2mm (martensite content is about 80%). When the high-temperature strip steel at about 700°C after soaking and slow cooling enters the water quenching cooling tank 5 of the present invention through the entrance tension roller 2, the gas sealing device 4, etc., the water quenching nozzle 8 sprays 0.8-0.9Mpa desalted water at about 40°C Quickly cool the strip steel on the surface of the high-temperature strip steel in operation, and control the elongation rate of tension leveling to about 4-6% at the same time, adopt a higher belt speed V=260mpm=4.3m / s, 8 pairs of high-pressure water-cooled nozzles and two bends and one Straightening and straightening are all invested.

[0052] In this embodiment, by controlling the parameters of high-pressure water cooling, the steel plate is cooled to 290°C, and the warm straightening process is completed after the martensitic transformation occur...

example 3

[0053] Example 3, the steel strip to be cooled is 1000Mpa multi-phase steel (containing about 40% martensite and bainite) with a thickness of 1.0mm. After soaking and slow cooling, the temperature of the strip steel is about 620°C, and the structure contains about 60% ferrite, 10% bainite and 30% austenite. When the strip steel passes through the entrance tension roller 2, gas sealing device 4, etc. When entering the water quenching cooling tank 5 of the present invention, the water quenching nozzle 8 sprays 0.7-0.8Mpa desalted water at about 65°C to the surface of the high-temperature strip steel in operation to rapidly cool the strip steel, and at the same time control the elongation rate of tension leveling by about 4-7% , using tape speed V=200mpm=3.3m / s, and 8 pairs of high-pressure water-cooled nozzles and two bends and one straightening are all put into use.

[0054] In this embodiment, by controlling the parameters of high-pressure water cooling, the steel plate is coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com