Polytetrafluoroethylene fiber self-lubricating sealing strip suitable for sealing doors and windows of carriage

A technology of polytetrafluoroethylene and sealing strips, which is applied in sealing devices, textiles, papermaking, knitting, etc., to achieve the effects of enhanced bonding strength, low friction coefficient, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

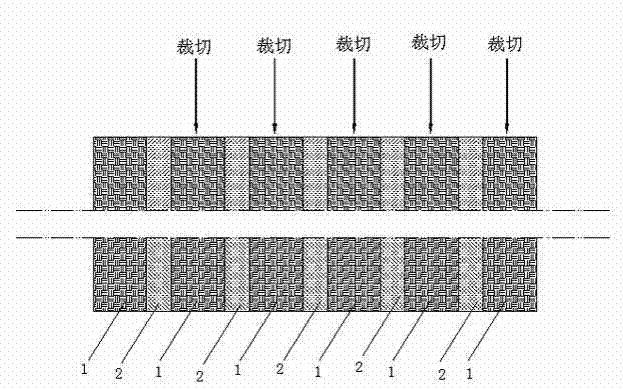

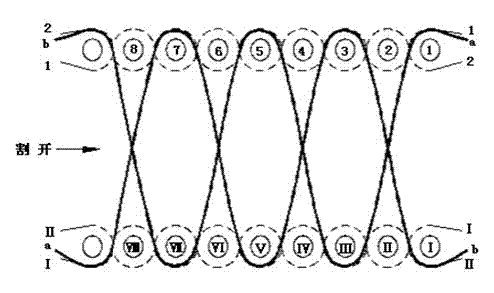

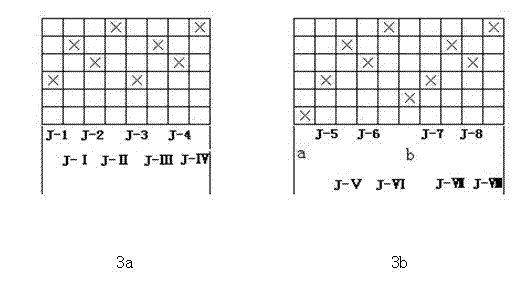

[0034] figure 1 Shown is that the polytetrafluoroethylene fiber self-lubricating sealing strip is an embodiment of the present invention, which is composed of a base layer that plays a fixing role and a fleece layer on the upper surface of the base layer. The base layer is a braided fabric made of polyester filaments 200d / 24f, and the velvet layer is a velvet formed by knitting polytetrafluoroethylene (PTFE) filaments 400d / 60f on the base layer braided fabric through a double-layer warp raising knitting method. The friction coefficient of the polytetrafluoroethylene fiber self-lubricating sealing strip: 0.16-0.20; operating temperature: -60°C-200°C; speed: ≤5m / s; pressure: ≤200Pa.

[0035] The self-lubricating sealing strip of this embodiment adopts the double rapier loom in the double-layer loom to weave the double-layer warp raising weaving method, that is, two system warp yarns (ground warp and pile warp) are used, and the same system weft yarn is interwoven made. When w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com