Coated fine metal particle and process for producing the same

一种金属微粒、制造方法的技术,应用在金属加工设备、运输和包装、薄料处理等方向,能够解决不能满足磁珠子高耐腐蚀性、金属微粒烧结、生产效率低等问题,达到沉降速度慢、简单耐腐蚀性、高耐腐蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

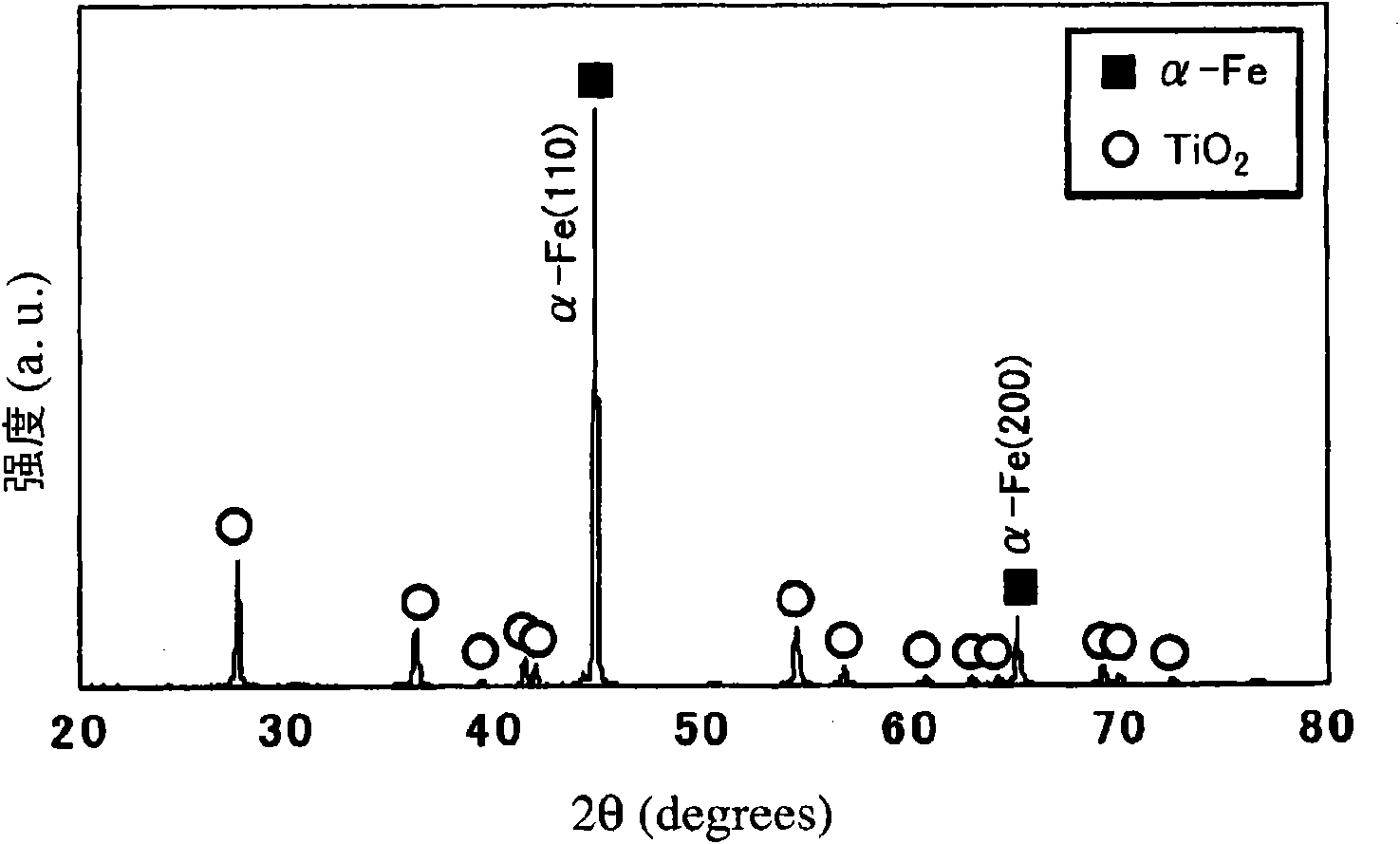

[0097] α-Fe with a median particle size of 0.03 μm 2 o 3 The powder and TiC powder with a median particle size of 1 μm were mixed with a ball mill at a mass ratio of 7:3 for 10 hours, and the resulting mixed powder was heat-treated in an alumina boat at 700°C for 2 hours in nitrogen. The X-ray diffraction pattern of the sample powder obtained is shown in figure 1 middle. figure 1 The horizontal axis of represents the 2θ (°) of diffraction, and the vertical axis represents the diffraction intensity (relative value). As a result of analysis based on the analysis software "Jade, Ver.5" manufactured by MDI Corporation, the diffraction peaks were identified as α-Fe and TiO 2 (rutile structure).

[0098] The average crystallite size of Fe calculated from the half-value width of the (200) peak of α-Fe using the Scherrer formula was 90 nm. TiO obtained at 2θ=27.5° 2 The half value width of the largest diffraction peak is 0.14, TiO 2 The ratio of the intensity of the maximum dif...

reference example 2

[0102] Reference example 2 to reference example 5

[0103] In addition to the α-Fe 2 o 3 Except that the masses of the powder and TiC powder were changed as shown in Table 1, sample powder was produced and purified in the same manner as in Reference Example 1 to obtain magnetic particles. The composition and magnetic properties of these magnetic particles were measured in the same manner as in Reference Example 1. The results are shown in Table 1.

[0104] α-Fe 2 o 3 The magnetic particle of Reference Example 5 obtained by setting the mass ratio of powder to TiC powder to 4:6 has high corrosion resistance, but the saturation magnetization Ms becomes 48Am 2 / kg, less than 50Am 2 / kg, the coercive force iHc becomes 18kA / m, exceeding 15kA / m. From the above, it can be seen that the TiC compounding ratio is preferably 30 to 50% by mass in order to maintain a high saturation magnetization value by utilizing the characteristics of the metal Fe particles.

[0105] [Table 1]

...

reference example 6

[0110] Magnetic-coated metal fine particles were obtained in the same manner as in Reference Example 1 except that the heat treatment temperature was set to 800°C. The magnetic properties of this sample powder were measured in the same manner as in Reference Example 1. The amount of C in the sample powder was measured by a high-frequency heating infrared absorption method (EMIA-520 manufactured by HORIBA), and the amount of N was measured by a heat conduction method (EMGA-1300 manufactured by HORIBA) in an inert gas. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com