Preparation method of lanthanum europium molybdate red luminescent powder

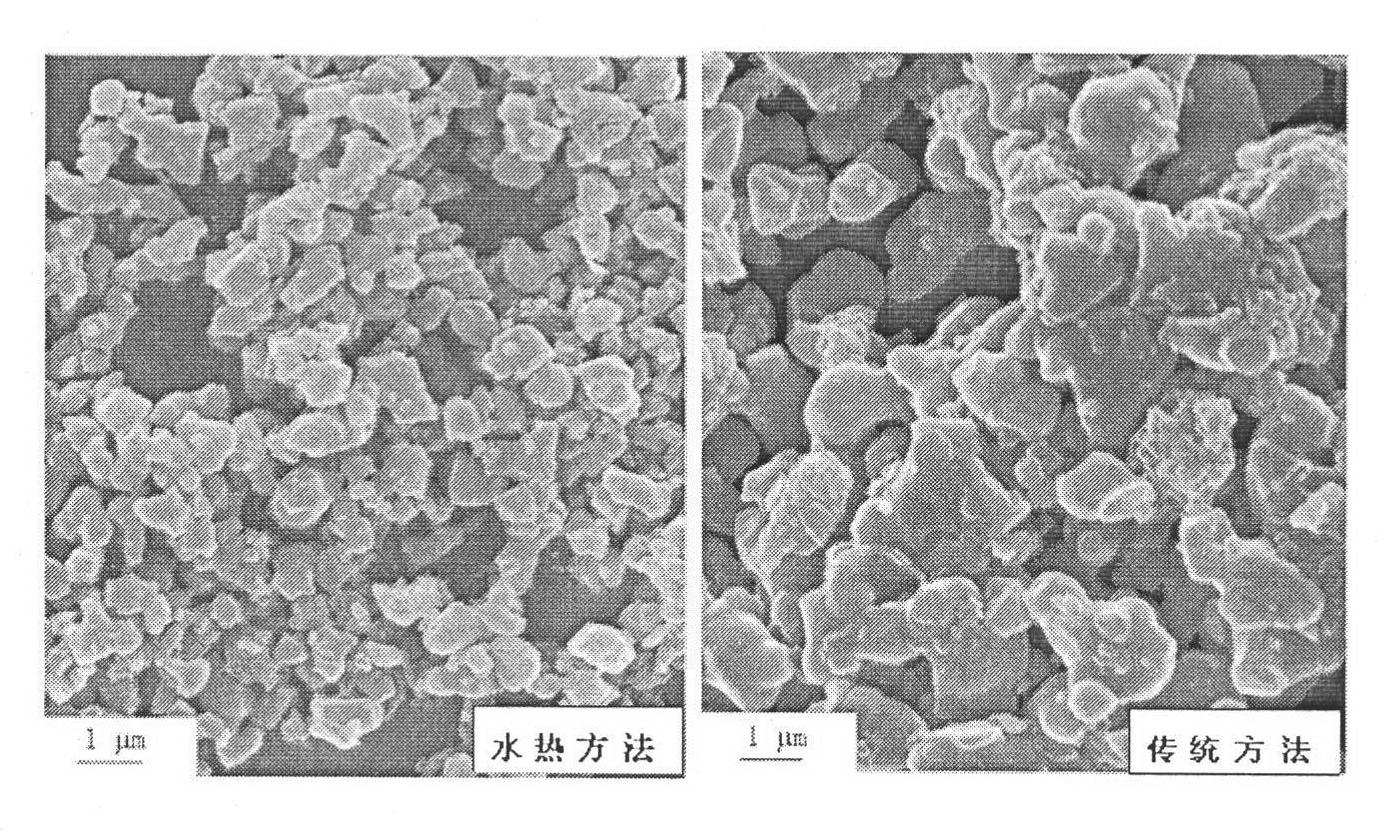

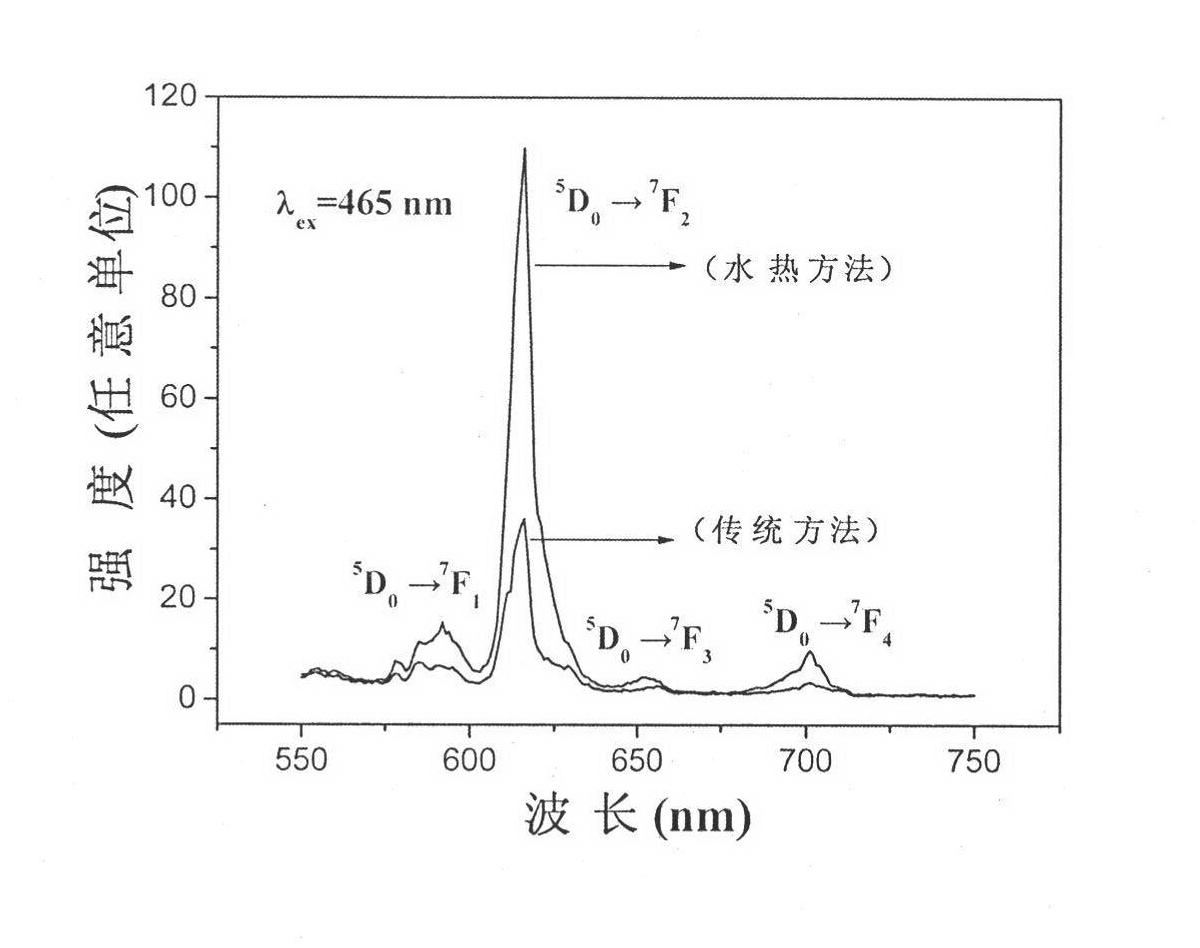

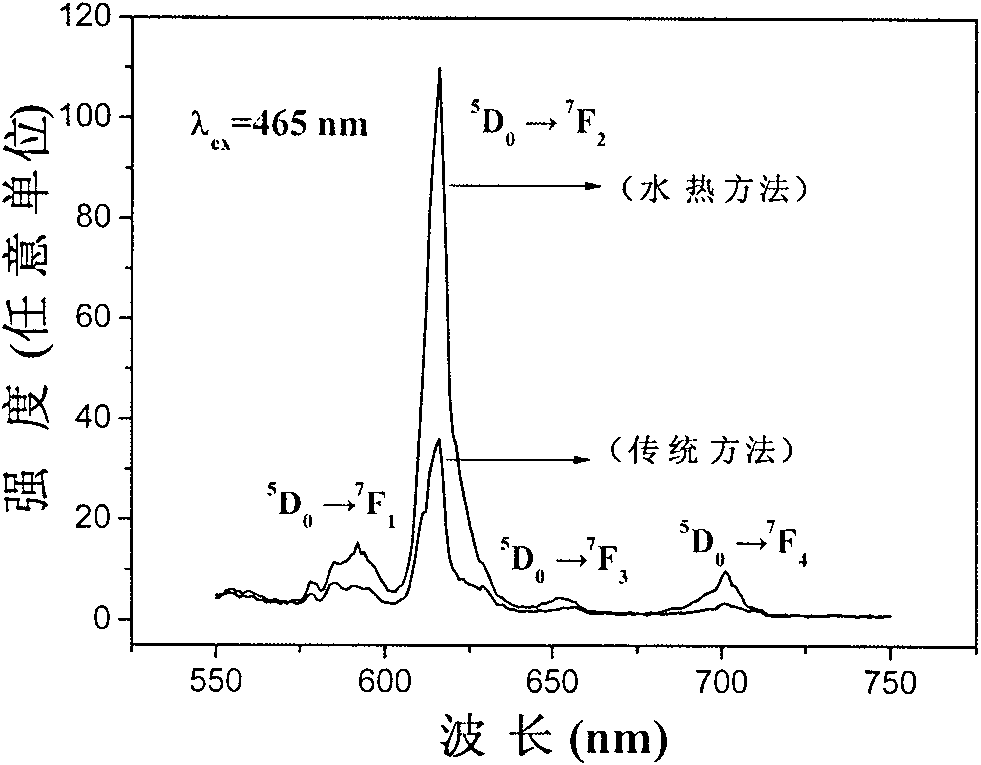

A technology of red luminescence and lanthanum molybdate, which is applied in the direction of luminescent materials, chemical instruments and methods, and the use of gas discharge lamps, can solve the problems of reduced luminous efficiency and difficulty in accurately perfecting the chemical composition, and achieve regular powder morphology, Uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Lanthanum oxide and europium oxide are dissolved in nitric acid respectively to make lanthanum nitrate and europium nitrate solutions, the concentration of lanthanum nitrate solution is 0.3mol / L, and the concentration of europium nitrate solution is 0.2mol / L; dissolve heptamolybdenum with 18ml deionized water Ammonium heptamolybdate 1.410g is mixed with ammonium heptamolybdate solution to make the ammonium heptamolybdate solution concentration 0.06mol / L;

[0021] (2) Take 18.6ml of lanthanum nitrate solution and 12.0ml of europium nitrate solution, add 15ml of water and stir to form a mixed solution, then add 3.2ml of surfactant (PEG 400) to the mixed solution, and keep stirring;

[0022] (3) Ammonium heptamolybdate solution is added dropwise in the above-mentioned mixed solution, and then a small amount of 6mol / L ammonia water is added to adjust the pH value of the solution to 8.5 to form a suspension;

[0023] (4) Transfer the suspension to a 100ml high-pressure r...

Embodiment 2

[0026] (1) Lanthanum oxide and europium oxide are dissolved in nitric acid respectively to make lanthanum nitrate and europium nitrate solution, the concentration of lanthanum nitrate solution is 0.3mol / L, and the concentration of europium nitrate solution is 0.2mol / L; dissolve heptamolybdenum with 12ml deionized water Ammonium heptamolybdate 1.130g is mixed with ammonium heptamolybdate solution to make the ammonium heptamolybdate solution concentration 0.08mol / L;

[0027] (2) Take 14.9ml of lanthanum nitrate solution and 9.6ml of europium nitrate solution, add 20ml of water and stir to form a mixed solution, then add 2.6ml of surfactant (PEG 400) into the mixed solution and keep stirring.

[0028] (3) Add the ammonium heptamolybdate solution dropwise to the above mixed solution, and then add a small amount of 6mol / L ammonia water to adjust the pH value of the solution to 8.5 to form a suspension.

[0029] (4) Transfer the suspension to a 100ml high-pressure reactor, and condu...

Embodiment 3

[0032] (1) Lanthanum oxide and europium oxide are dissolved in nitric acid respectively to make lanthanum nitrate and europium nitrate solutions, the concentration of lanthanum nitrate solution is 0.3mol / L, and the concentration of europium nitrate solution is 0.2mol / L; dissolve heptamolybdenum with 15ml deionized water Ammonium heptamolybdate 1.805g is mixed with ammonium heptamolybdate solution to make the ammonium heptamolybdate solution concentration 0.10mol / L;

[0033] (2) Take 23.8ml of lanthanum nitrate solution and 15.3ml of europium nitrate solution, add 5ml of water and stir to form a mixed solution, then add 4.1ml of surfactant (PEG 400) to the mixed solution and keep stirring.

[0034] (3) The ammonium heptamolybdate solution was added dropwise to the above mixed solution, and then a small amount of 6 mol / L ammonia water was added to adjust the pH value of the solution to 8.5. A suspension was formed.

[0035] (4) Transfer the suspension to a 100ml high-pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com